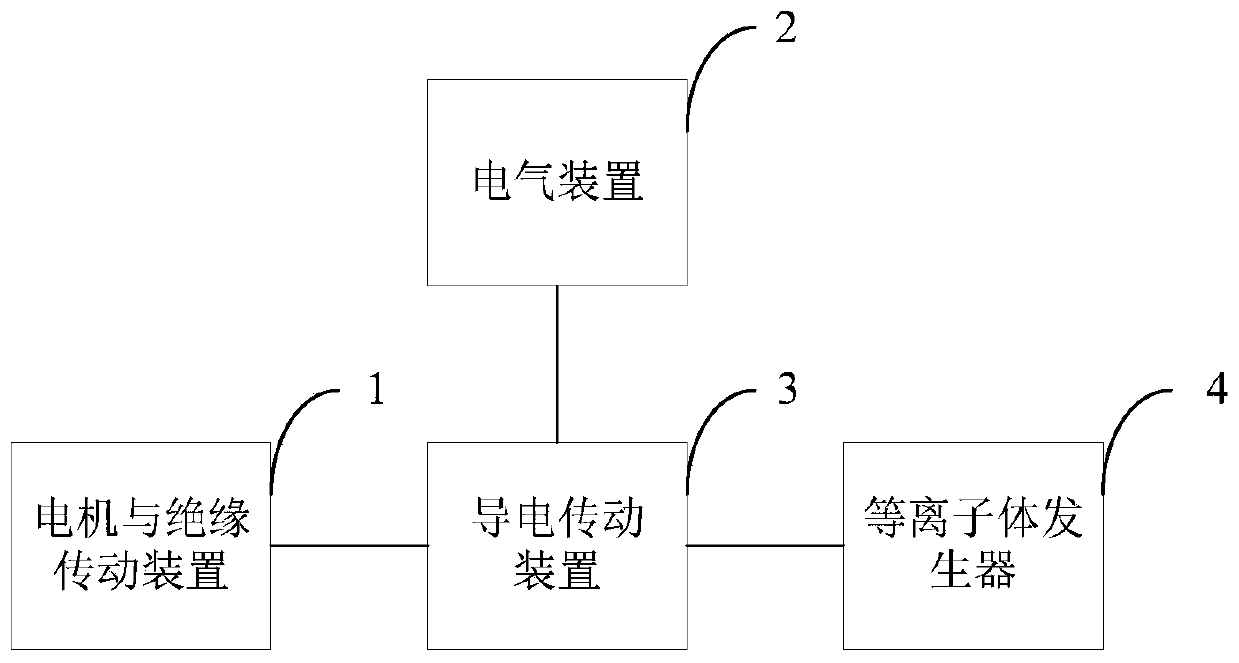

Atmospheric pressure plasma jet device

A plasma and jet device technology, applied in the field of plasma, can solve problems such as difficulty, and achieve the effects of high application efficiency, high discharge efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

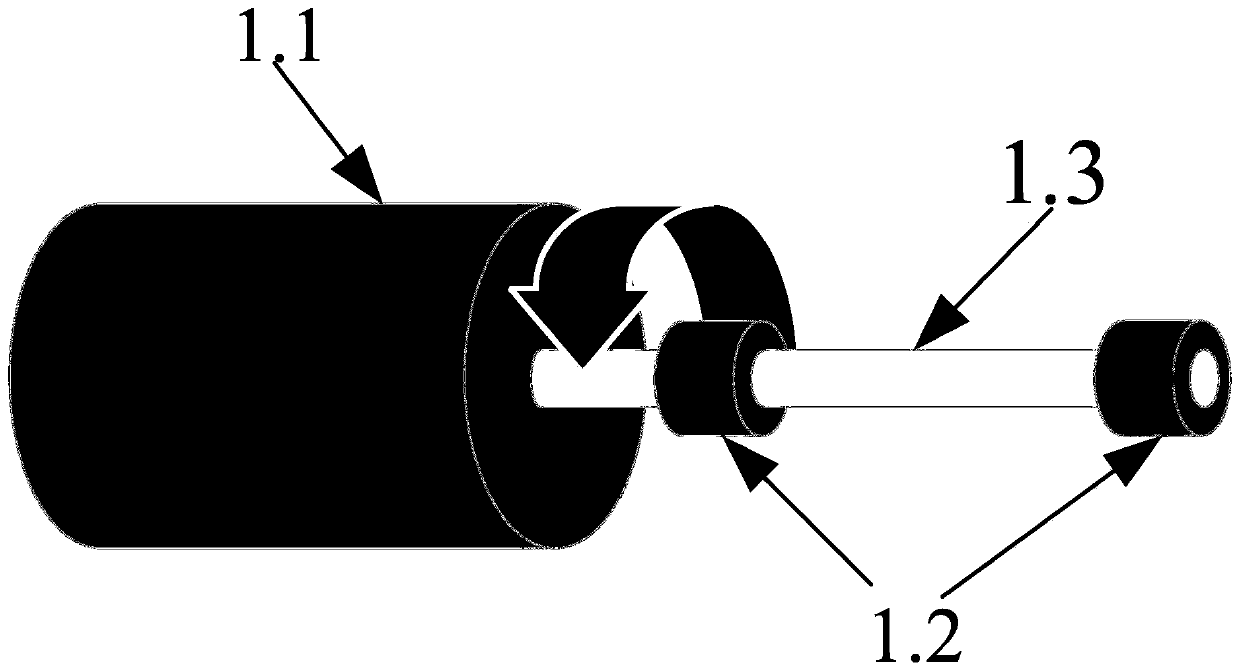

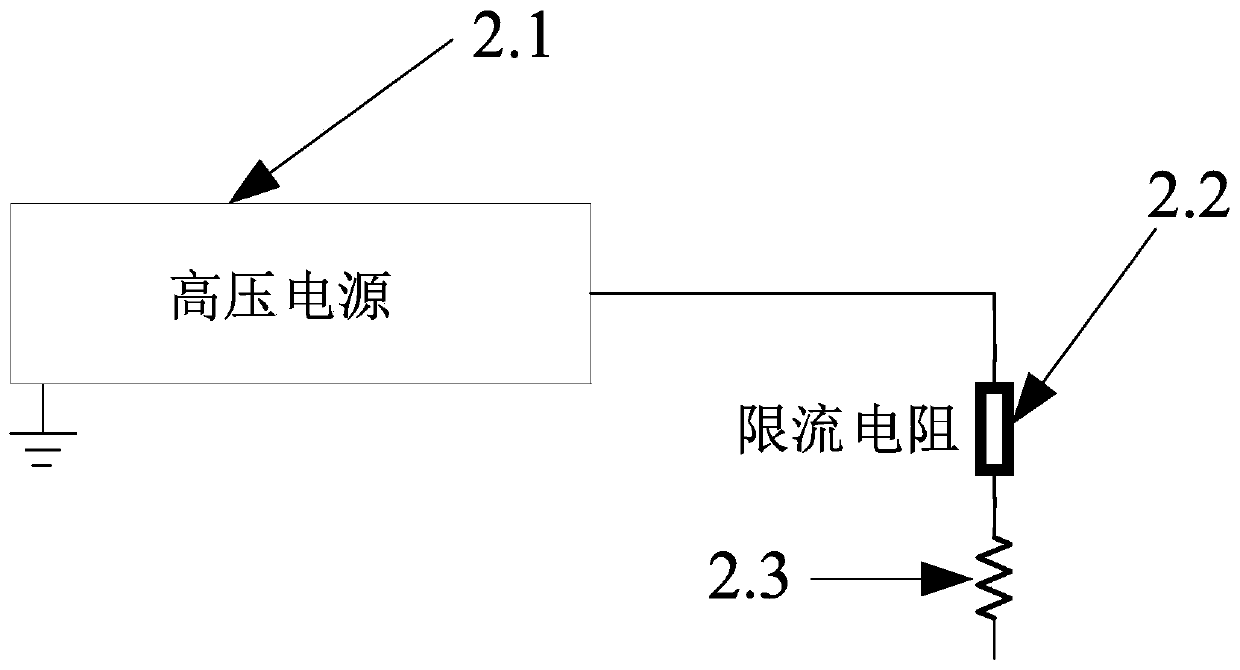

Embodiment 1

[0057] In the embodiment of the present invention, air is used as the working gas; the rotating electrode is used as the high voltage electrode, and the fixed electrode is used as the ground electrode; the speed of the motor is selected to be 5000r / min; the coupling is made of polytetrafluoroethylene; the transmission connecting rod is made of alumina ceramics Material; the brush is made of graphite; the fixing device of the brush is made of polytetrafluoroethylene; the shaft is made of stainless steel; the high-voltage wire is made of a high-voltage wire with a withstand voltage of 20kV; shaped, integrally formed with the shell of the plasma generator; the rotating electrode is in the shape of a four-pointed star, and its material is stainless steel; the panel where the nozzle is located is made of alumina ceramic sheet; the nozzle is rectangular, obtained by cutting on the alumina ceramic panel; the fixed electrode is made of metal , the material is stainless steel; the base ...

Embodiment 2

[0067] as attached Image 6As shown, in the embodiment of the present invention, the fixed electrodes are set to be arranged on both sides of the nozzle. The nozzle is rectangular, 1 cm long and 2 mm wide. breath. Air is used as the discharge gas, the fixed electrode is used as the high voltage electrode, and the rotating electrode is used as the ground electrode.

Embodiment 3

[0071] as attached Figure 8 As shown, in the embodiment of the present invention, the telescopic motor controls the vertically telescoping electrode 4.8 to stretch up and down through the insulating transmission device, and the high-voltage power supply supplies power to the telescopic electrode 4.8 through the conductive transmission device. In the initial state, the telescopic electrode 4.8 moves downward and approaches the fixed electrode 4.1. When the distance decreases to the maximum breakdown distance, the discharge starts to generate plasma flow. The sensor 4.7 detects the discharge and sends a signal to the telescopic motor to make it pull The telescopic electrode 4.8 is far away from the fixed electrode 4.1; as the distance becomes longer, the plasma flow will be elongated, and the discharge will gradually stop at the same time. After the sensor 4.7 detects that the discharge stops, it will send a signal to the telescopic motor to let it pull the telescopic electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com