Test device and method of cement mortar fluidity

A cement mortar and testing device technology, which is applied in the field of road engineering, can solve the problems of affecting performance, insufficient bearing capacity, inconvenient construction operation, etc., and achieve the effect of reasonable design, simple structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

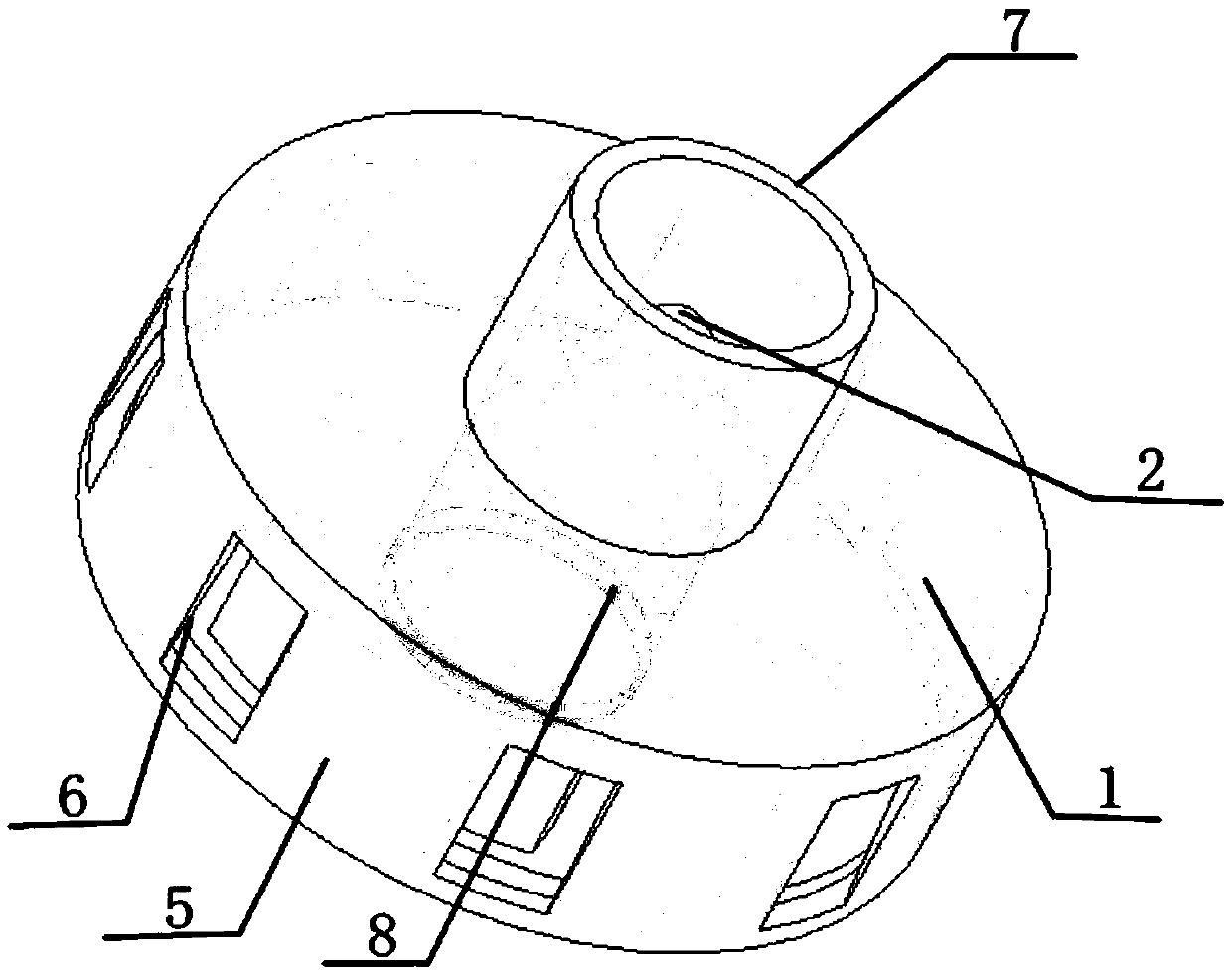

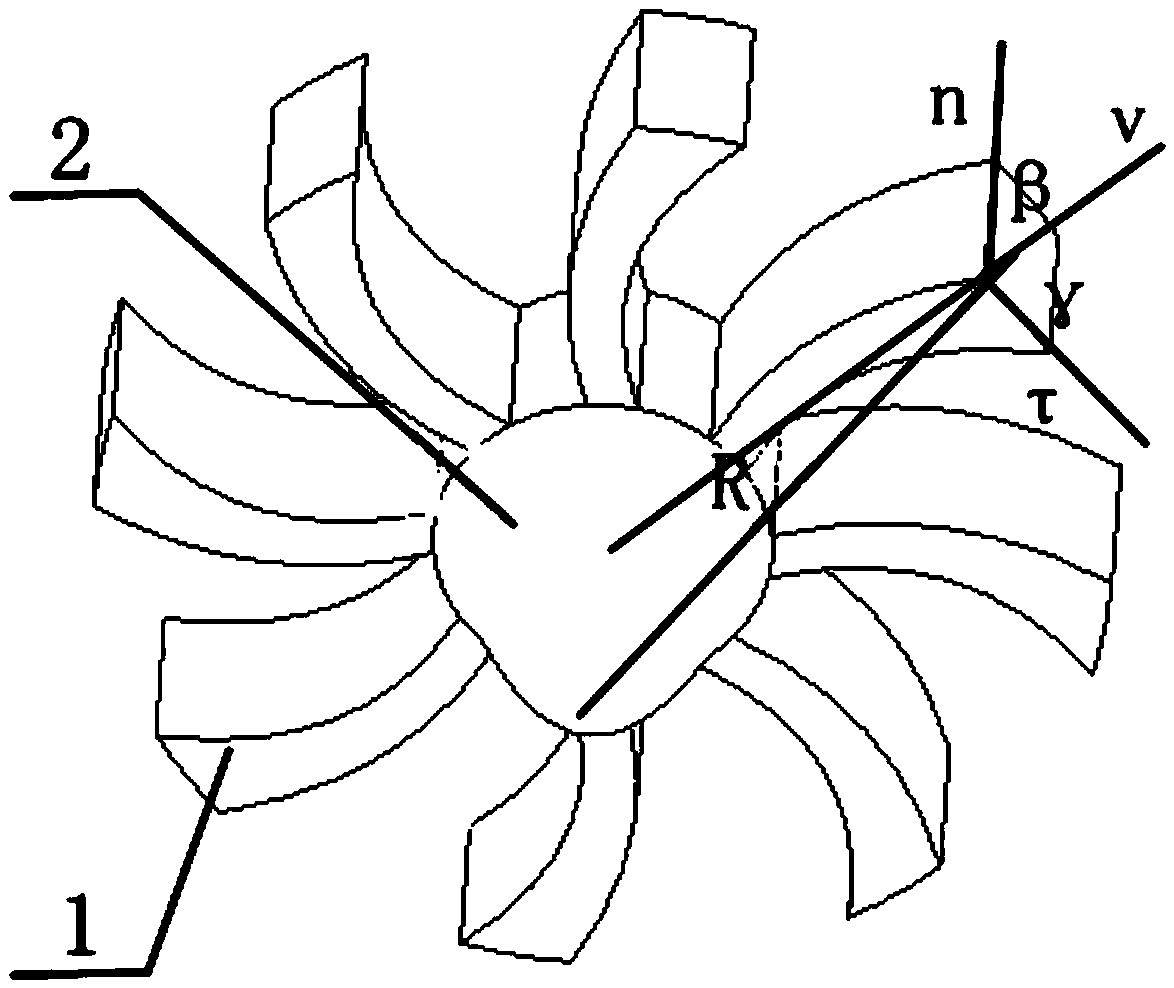

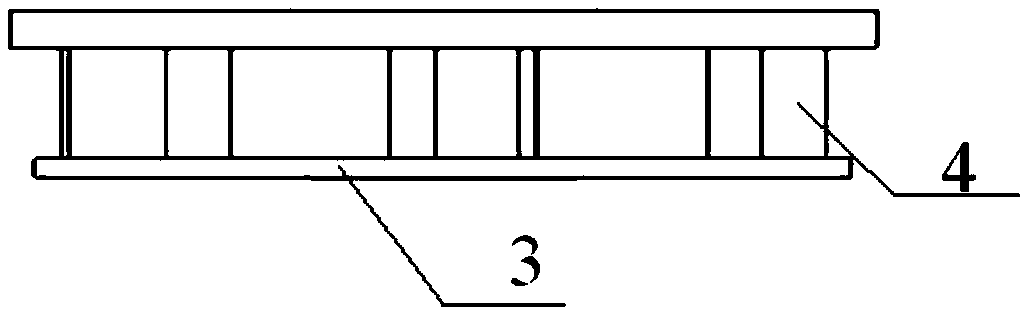

[0025] refer to figure 1 , the test device for the fluidity of cement mortar according to the present invention includes a cement mortar jet, a casing 5, a shaft, a turbine 1, a speed friction control sheet 4, a support, and a height-adjustable baffle; The central position is provided with a cement mortar inlet, the outlet of the cement mortar injection machine is connected with the cement mortar inlet, the side of the casing 5 is provided with a number of injection ports 6, the turbine 1 is located in the casing 5, and the front of the turbine 1 is provided with a cone The protrusion 2 of the shape structure, the protrusion 2 is facing the inlet of the cement mortar, one side of the speed friction control sheet 4 is fixed on the back of the turbine 1, and one side of the baffle is movably connected with the inner wall of the casing 5, the blocking The other side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com