Device for preparing microdroplets based on magnetofluid excitation technology jet breakup

A magnetic fluid and excitation technology, applied in the direction of additive processing, etc., can solve the problems of complex equipment, difficult air pressure pulse, and low frequency of droplet preparation, and achieve the effect of simplifying the test device and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

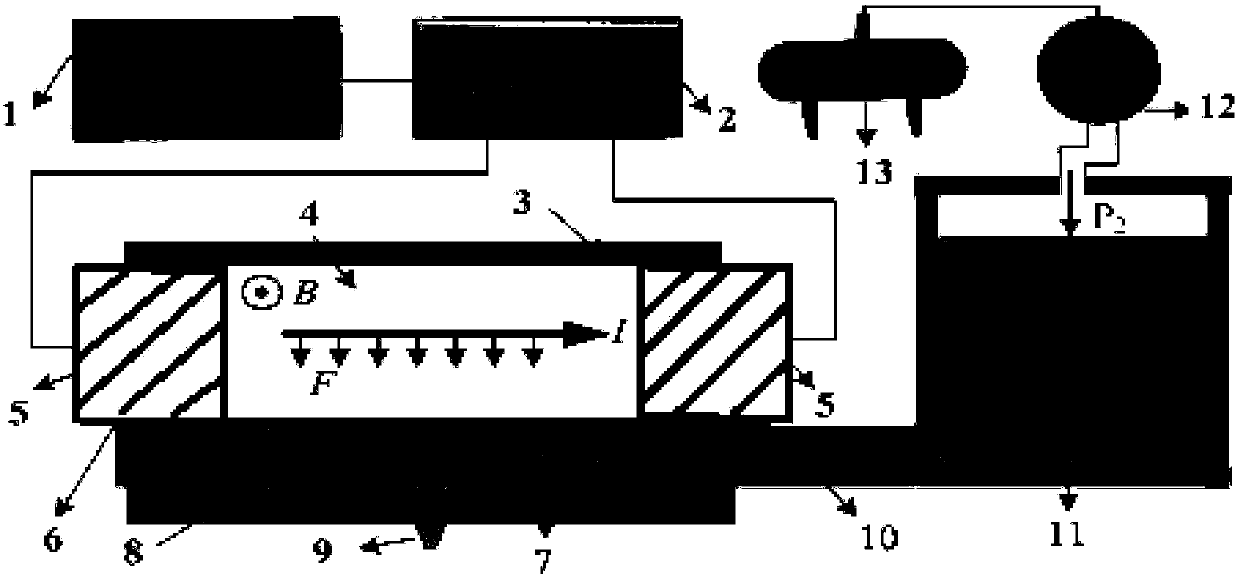

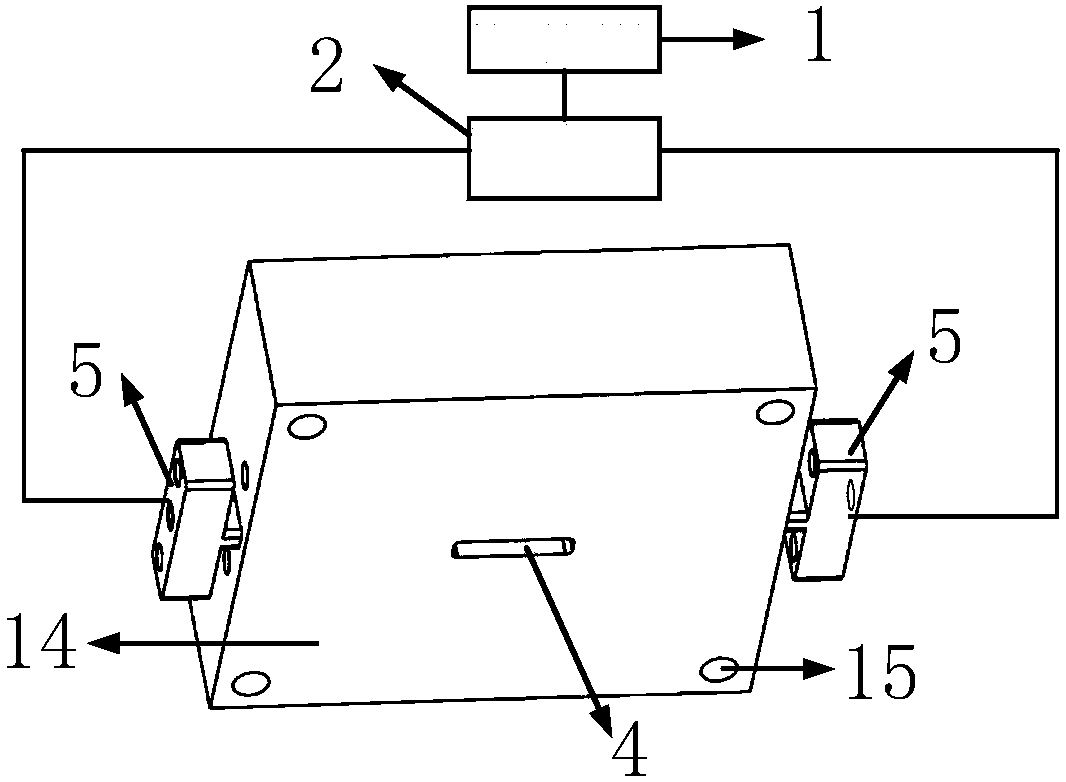

[0017] see Figure 1-2 , the embodiment of the present invention is provided with a signal generator 1, a power amplifier 2, a disturbance generator upper cover plate 3, a liquid metal placement chamber 4, a copper electrode 5, a diaphragm 6, an injection chamber 7, and a lower cover plate 8 with nozzles , Nozzle 9, Catheter 10, Liquid Storage Chamber 11, Pressure Reducing Valve 12, Air Compressor 13, Disturbance Generator 14, Device Fixing Hole 15.

[0018] A permanent magnet is loaded inside the disturbance generator 14 to generate a constant magnetic field. The copper electrode 5 is placed inside the disturbance generator 14, and the variable high-frequency electric signal generated by the signal source 1 and the power amplifier 2 is connected to the copper electrode 5 with its positive and negative poles. The liquid metal placement chamber 4 is filled with liquid metal, and the disturbance generator 14 and the injection chamber 7 are assembled together by the diaphragm 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com