Cell printing self-adaptive inkjet driving control method

A cell printing and self-adaptive technology, applied in tissue cell/virus culture devices, printing devices, biochemical equipment and methods, etc., can solve nozzle clogging, difficulty in ejecting high-viscosity and high-density liquids, and hinder cell Problems such as the realization of printing projects, to achieve the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The specific results and working principle of the piezoelectric nozzle:

[0065] (1) The specific structure of the piezoelectric nozzle

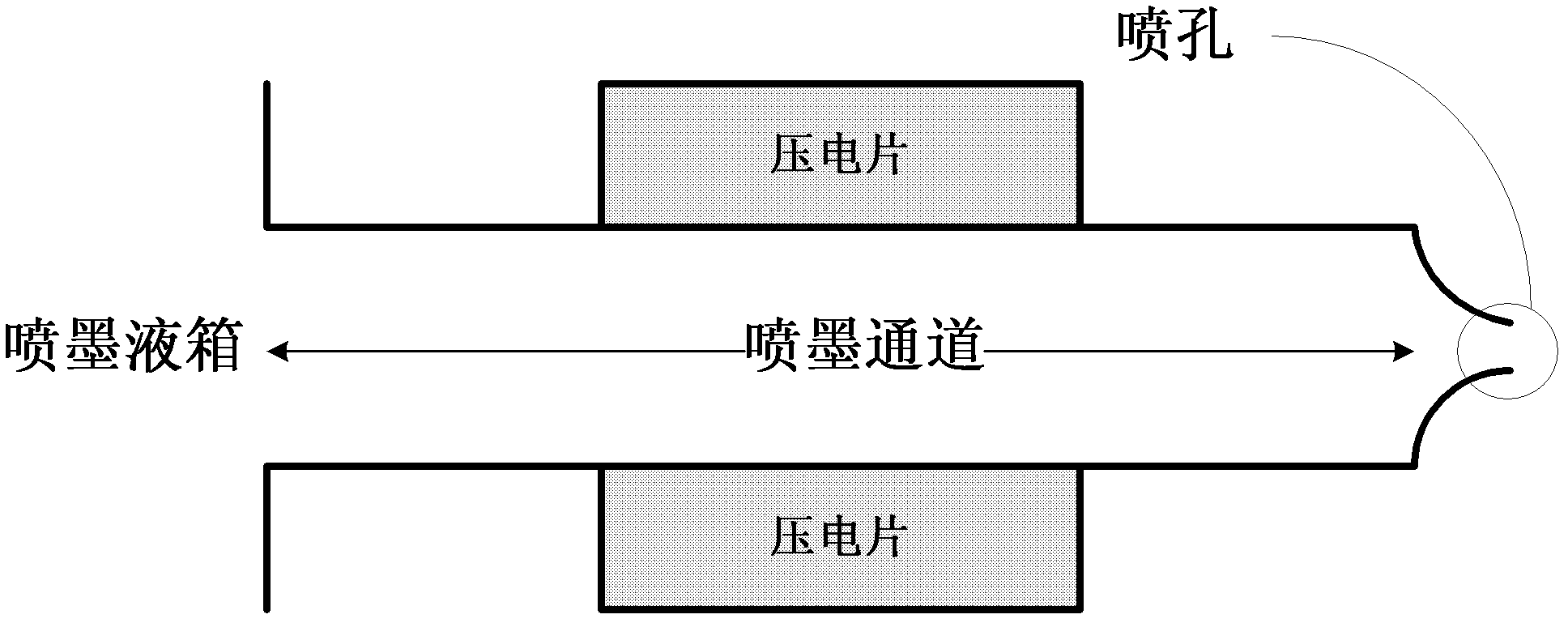

[0066] refer to figure 2 The schematic diagram of the structure of the piezoelectric nozzle shown includes an inkjet liquid tank, an ink jet channel, a nozzle hole and a piezoelectric sheet. One end of the ink jet channel is connected to the nozzle hole, and the other end communicates with the ink jet liquid tank. Electric sheets and piezoelectric sheets are distributed above and below the inkjet channel.

[0067] (2) Working principle of piezoelectric nozzle

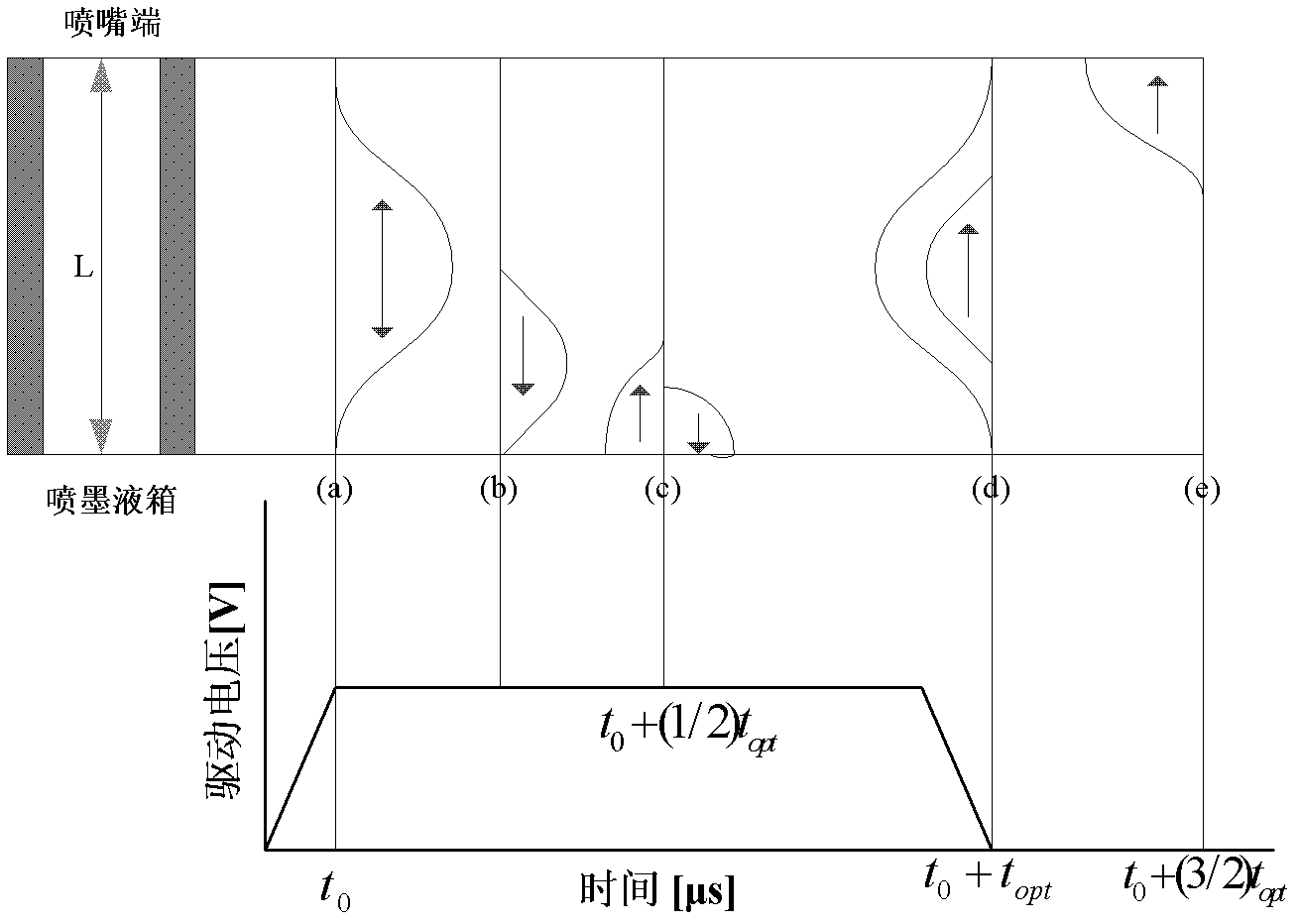

[0068] refer to figure 1 , at t 0 At this time, the driver applies a square wave signal with a width of T0 to the piezoelectric sheet, and the voltage causes the piezoelectric sheet to contract, forming a negative pressure in the inkjet channel chamber, and the negative pressure propagates toward the inkjet liquid tank (b); when it reaches At the inkjet liquid tank, becau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com