SCR urea injection protective system

A technology of urea injection and protection system, which is applied in exhaust gas treatment, mechanical equipment, engine components, etc., can solve the problem of low working efficiency of SCR system, avoid urea crystals from blocking nozzles, slow down the reduction of exhaust gas temperature, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

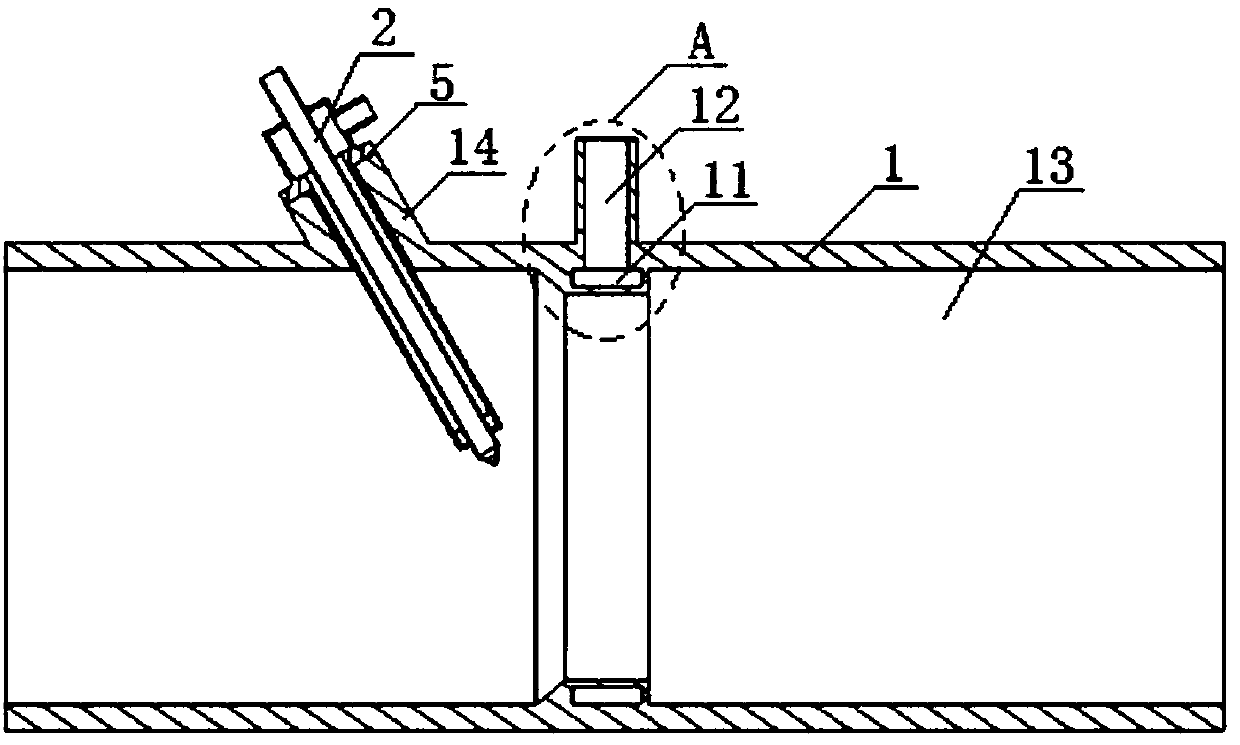

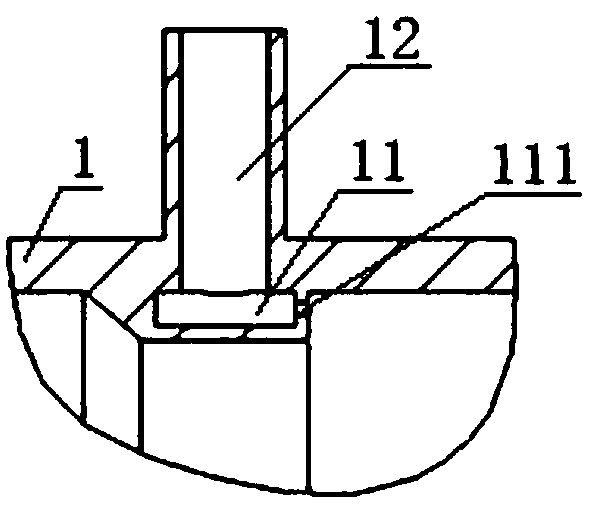

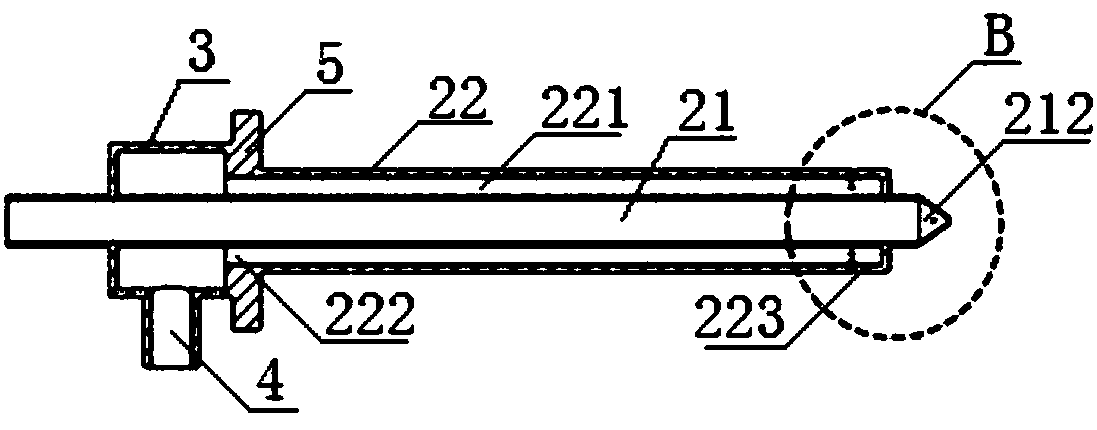

[0045] see Figure 1 to Figure 4 , an SCR urea injection protection system, comprising an exhaust pipe 1, a urea nozzle assembly 2 whose urea injection end is inserted into the exhaust pipe 1, the exhaust pipe 1 is provided with an annular air cavity 11 along its inner wall, the One side of the annular air cavity 11 is communicated with the outside of the exhaust pipe 1 through the intake passage 12 , and the other side of the annular air cavity 11 is evenly provided with a plurality of No. 1 air nozzle holes 111 that communicate with the inside of the exhaust pipe 1 . The air injection holes 111 are disposed toward the exhaust gas outlet 13 of the exhaust pipe 1 . The urea injection nozzle assembly 2 includes a urea injection pipe 21 and an air cooling pipe 22 coaxially sleeved outside the urea injection pipe 21 . The urea injection pipe 21 It is a straight pipe structure, the angle formed by it and the pipe wall of the exhaust pipe 1 is 135°, the liquid inlet end of the urea...

Embodiment 2

[0047] see Figure 5 , the structure is the same as that of Example 1, the difference is:

[0048] The urea injection pipe 21 is an L-shaped elbow structure, including a vertical pipe 213 and a horizontal pipe 214. The angle formed by the vertical pipe 213 and the wall of the exhaust pipe 1 is 90°. The spray end of 214 extends into the area enclosed by the annular air cavity 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com