Liquid raw material spraying method and device used for three-dimensional printing

A liquid raw material and three-dimensional printing technology, applied in the field of additive manufacturing, can solve the problems of low controllability of electric field jetting process, low controllability of high-voltage electric field, and low controllability of droplets, and achieve strong maintainability, High controllability, low power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

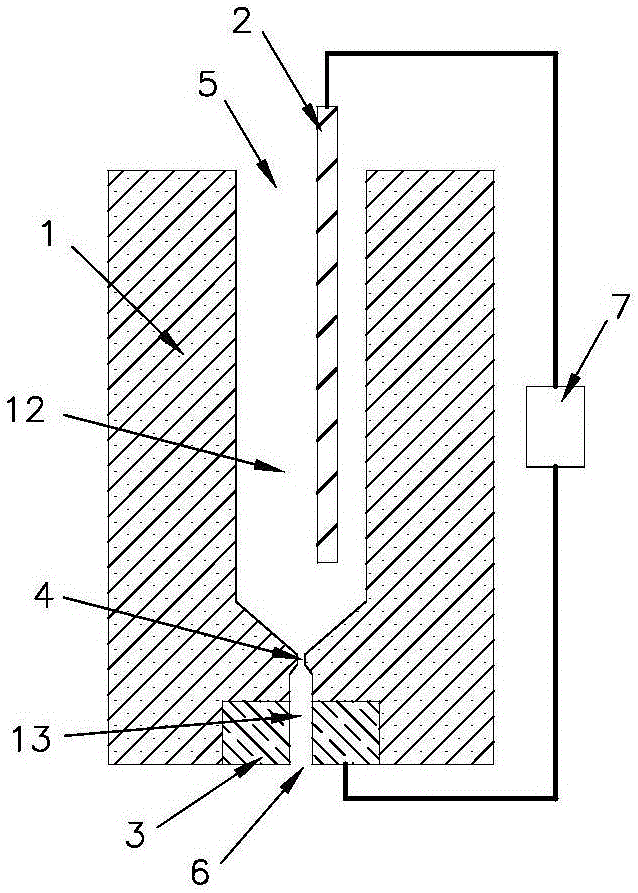

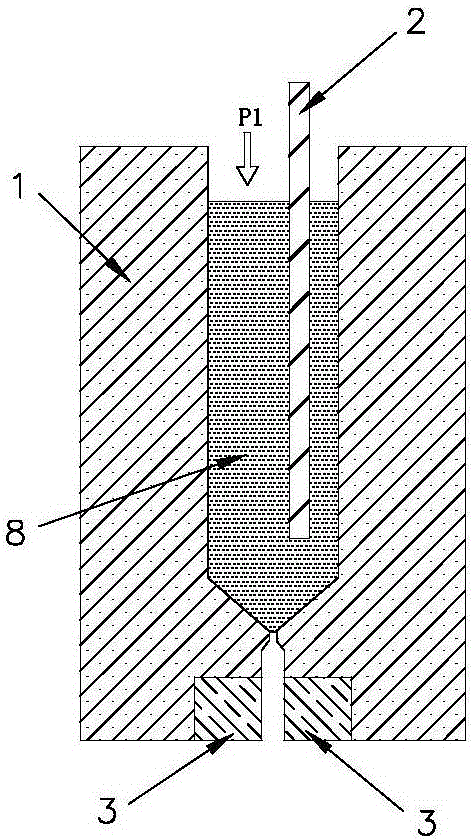

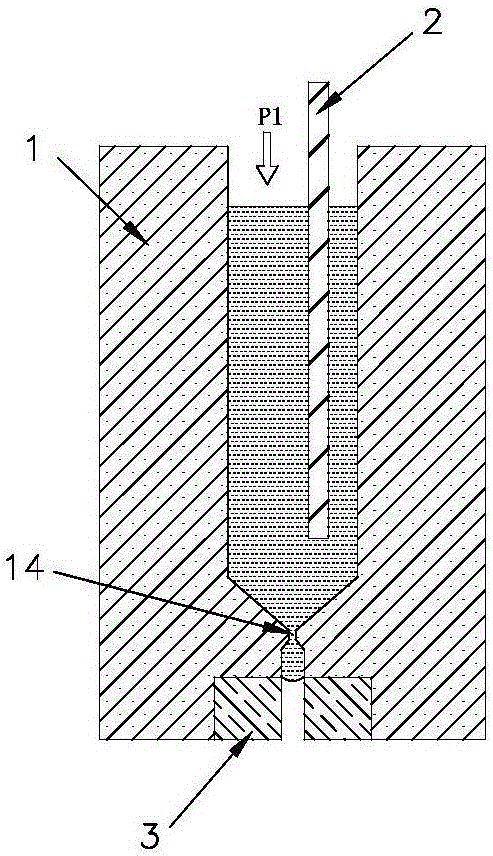

[0087] Such as Figure 8 Shown is a second specific embodiment of a liquid material ejection device for three-dimensional printing of the present invention, which is an application Figure 9 to Figure 12 The second specific embodiment of a liquid raw material ejection method for three-dimensional printing shown in the present invention: a liquid raw material ejection device for three-dimensional printing, which is mainly controlled by a housing (i.e. housing two 18), circuit (i.e. control circuit two 25) and a heating unit (not shown in the accompanying drawings); wherein: two raw material inlets (i.e. raw material inlet two 23 and raw material inlet three 24) and one The raw material outlet (namely raw material outlet 22), is provided with an electrode (ie electrode 3 19) at the raw material outlet; there is a flow channel inside the shell 2 18, and the number of flow channels is two; the first flow channel is the main flow channel , the main flow channel runs through the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com