Jetting glue dispensing valve device and jetting glue dispensing method

A spray point and glue valve technology, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of inconsistent volume of sprayed glue, decreased packaging quality, and difficulty in spraying large-viscosity glue, and achieves motion symmetry. And the effect of uniform, uniform and tidy movement, and symmetrical, uniform and tidy glue movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

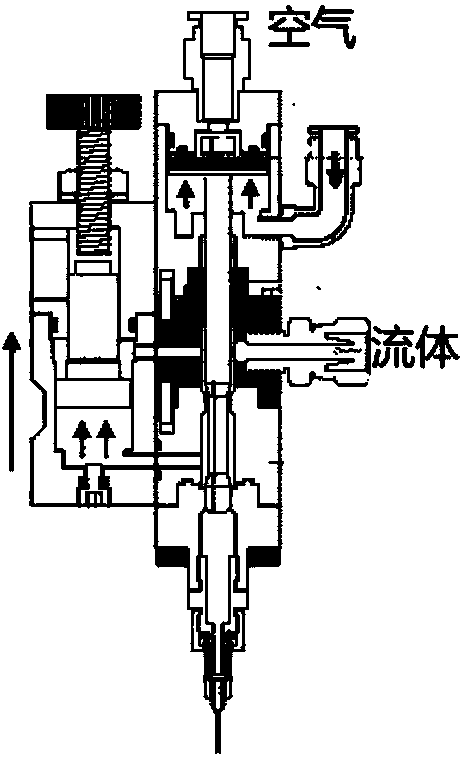

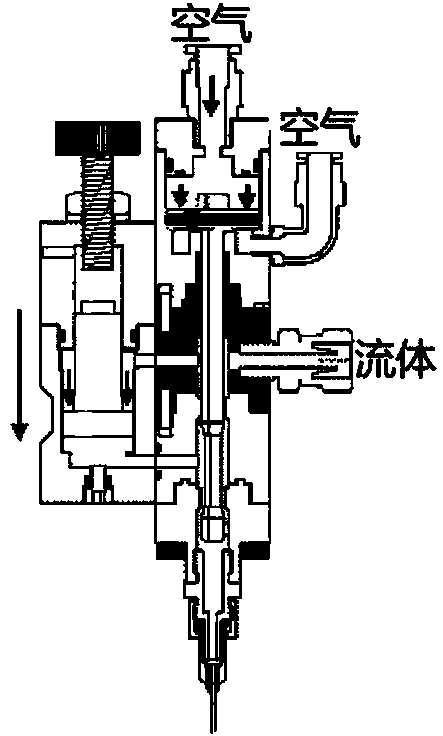

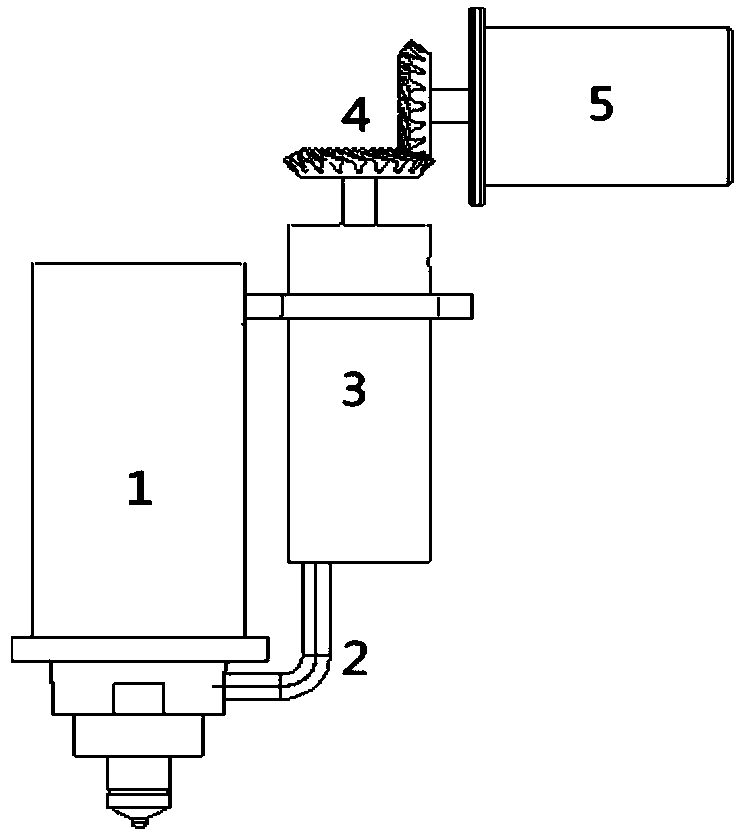

[0032] Such as image 3 and Figure 4 As shown, it is a schematic diagram of the device structure of the present invention, a jet dispensing valve device, including a jet dispensing valve main body 1, a glue supply valve 3 and a glue supply pipeline 2, and the jet dispensing valve main body 1 is provided with a tail end Connect the striker 10 of the spring 6 and the first air supply hole 7 that inflates the injection dispensing valve cavity 8 from the outside; the glue supply valve 3 is provided with a second air supply hole 14 that inflates the glue supply valve cavity 13 from the outside, and the injection point The glue valve cavity 8 communicates with the glue supply valve 3 through the glue supply pipeline 2; it is characterized in that it also includes a transmission gear 4, a drive motor 5 and a turntable 12 arranged inside the glue supply valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com