Electric or pneumatic continuous syringe

A syringe and electric drive technology, applied in veterinary instruments, medical science, etc., can solve the problems of continuous injection without better design and modification, and achieve the effect of improving injection accuracy and reducing injection fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

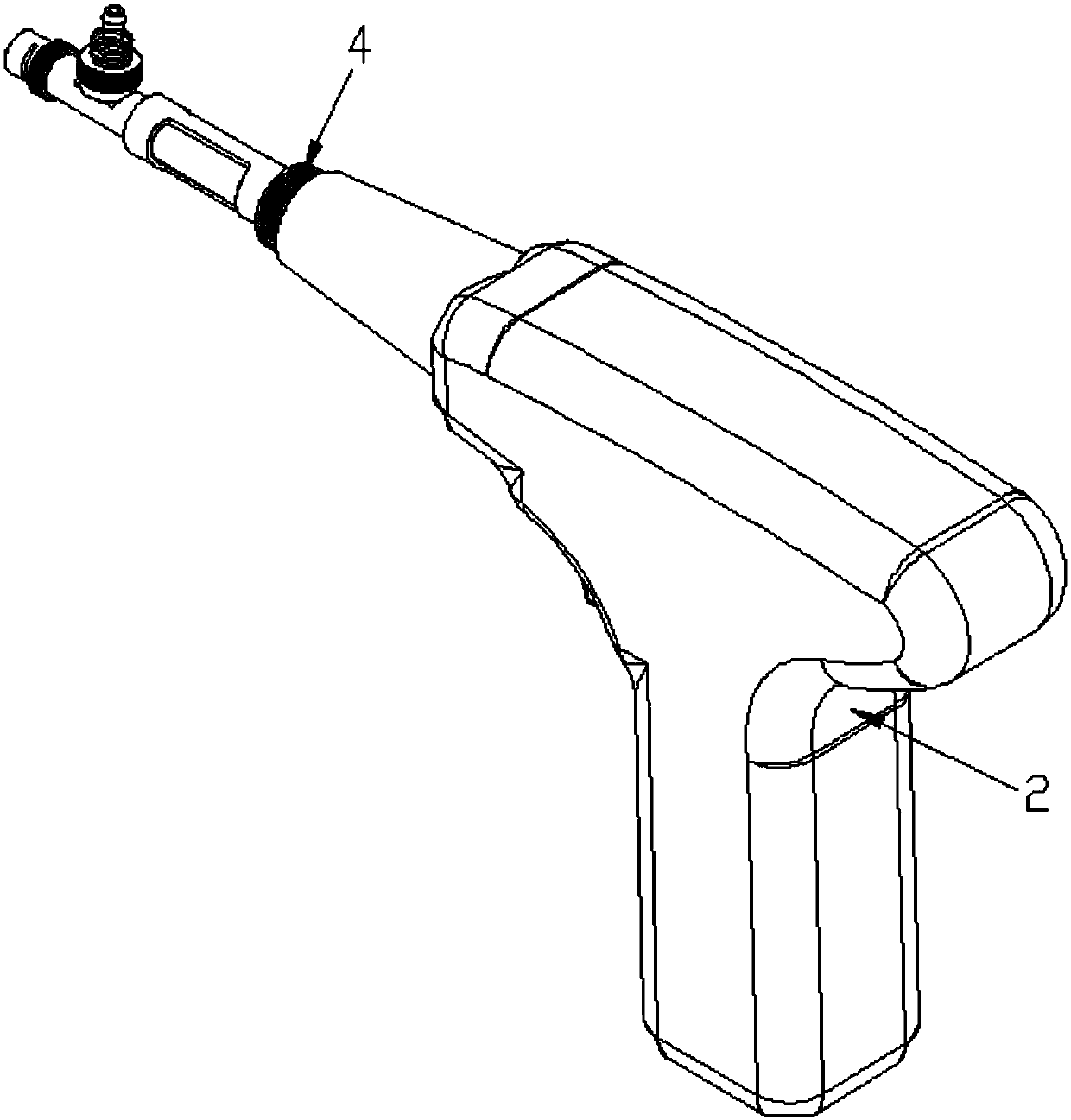

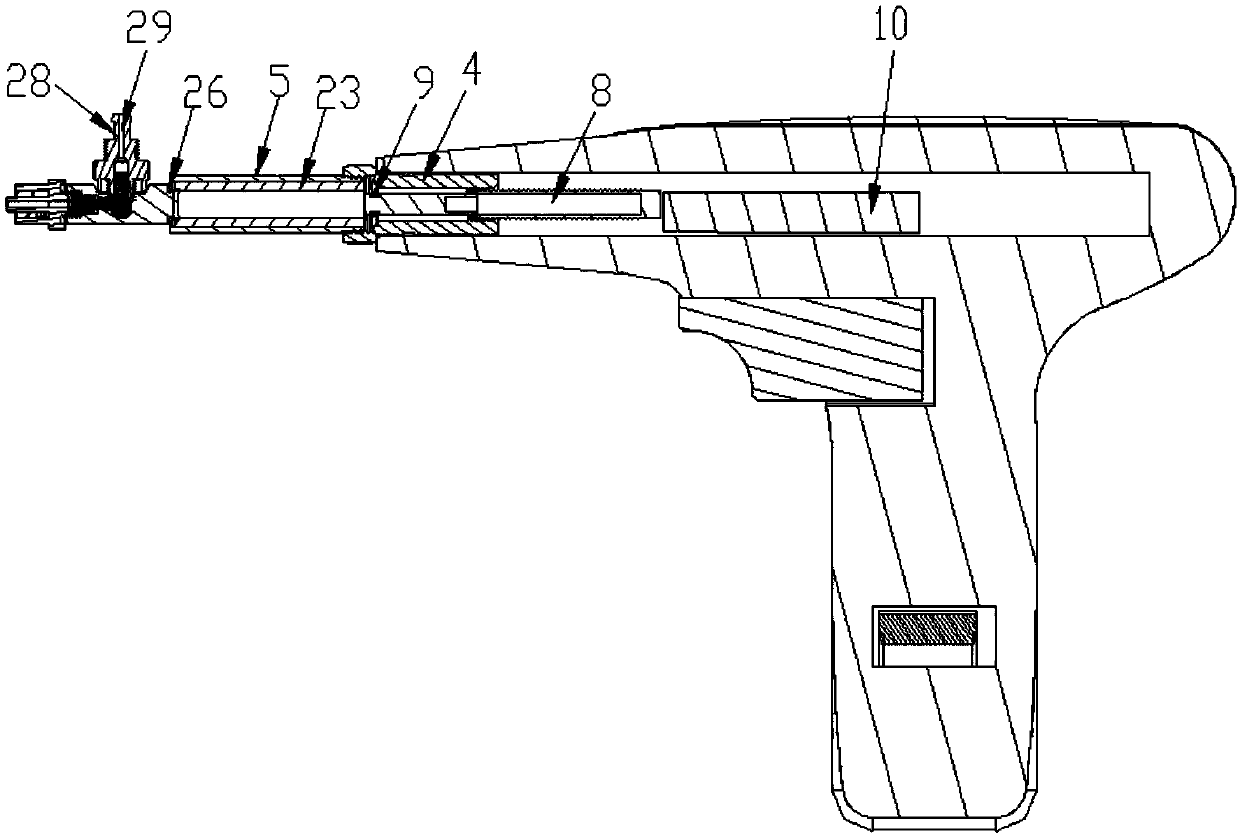

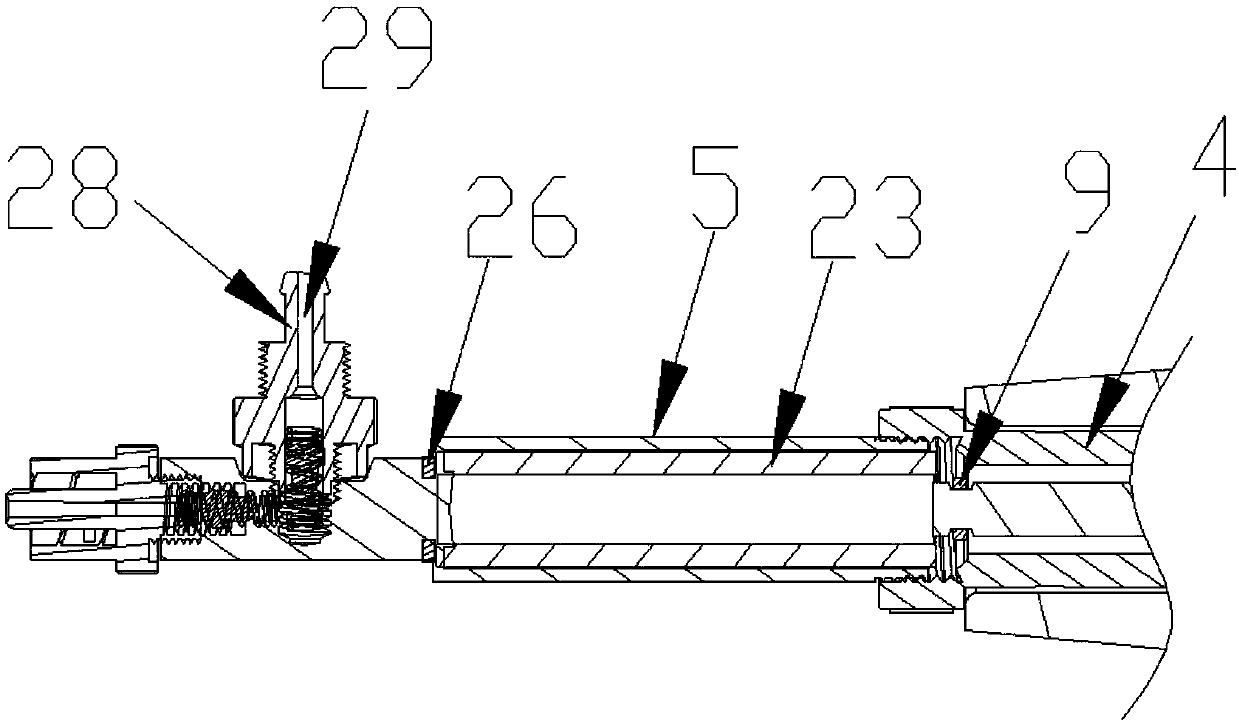

[0038] Such as Figure 1 to Figure 13 shown (for ease of illustration, Figure 1 to Figure 11All parts of the push rod drive mechanism are not shown, only the movable rod 10 inside is shown), the present invention is an electric or pneumatic continuous injector, including a handle 2 provided with a grip end 1, and the handle 2 also includes two A cavity 3 that runs through the handle 2 is provided between the opposite end and the two ends, and one end of the connecting shaft 4 of the push rod sleeve is arranged in the cavity 3, and the liquid medicine cartridge 5 is connected with the push rod sleeve through the connection structure 6 The other end of the shaft 4 is detachably connected, the liquid pumping port 7 is set on the liquid medicine cylinder 5, the push rod 8 is slid inside the liquid medicine cylinder 5, the piston 9 is set at one end of the push rod 8, and the other end of the push rod 8 is connected with the push rod The movable rod 10 of driving mechanism is fix...

Embodiment 2

[0040] The difference from Embodiment 1 is that, as Figure 14 As shown, the electric driving part includes a servo motor 20 arranged on the bottom wall of the cavity 3, the motor shaft of the servo motor 20 is connected with the gear 21 through a reducer, and the part facing the bottom wall of the cavity 3 on the movable rod 10 is connected with the gear 21. meshing racks.

Embodiment 3

[0042] The difference from Embodiment 1 is that, as Figure 15 As shown, the electric driving part includes a servo motor 20, and the servo motor 20 is arranged in the cavity 3 of the T-shaped handle. One side of the segment is in rolling connection with the friction wheel 37, and the other side of the friction segment is in rolling connection with the driven wheel 38, and the driven wheel 38 is connected with the housing of the T-shaped handle through a pin shaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com