Microdroplet spray device, and method for preparing CNTs film by deposition through microdroplet spray device

A technology of droplet jetting and thin film, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of poor quality of CNTs thin film, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

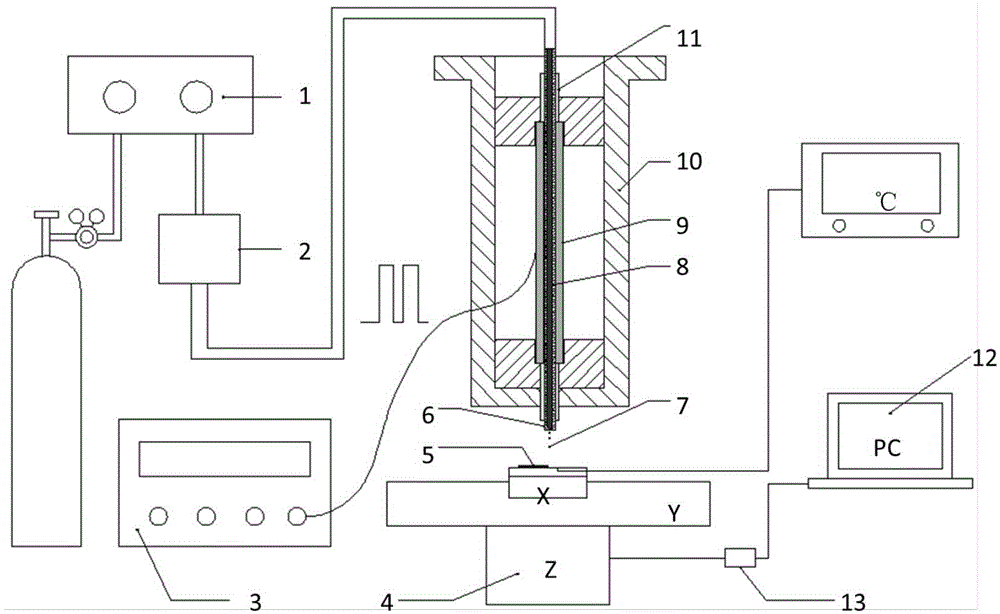

[0018] Reference figure 1 . The droplet ejection device of the present invention includes a pressure controller 1, a reservoir 2, a vibration driver 3, a three-dimensional motion substrate 4, a nozzle 6, a resonance glass tube 8, a piezoelectric ceramic tube 9, a fixed sleeve 10, a plastic tube 11, and a computer 12. And three-dimensional motion substrate controller 13. One end of the reservoir 2 is connected to the pressure controller 1, and the other end is connected to one end of the resonance glass tube 8 through a silicone hose. The other end of the resonant glass tube 8 is coaxially connected to the nozzle 6 through the plastic tube 11, and the two ends of the piezoelectric ceramic tube 9 are fixed by stepped holes on the fixing sleeve 10. There is a gap between the fixing sleeve 10 and the piezoelectric ceramic tube 9 To fill the sealant. The nozzle 6 is coaxial with the resonant glass tube 8 and the plastic tube 11. The resonant glass tube 8 is fixed in the piezoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com