Fuel shooting valve

A fuel injection valve and fuel flow technology, which is applied to fuel injection devices, charging systems, engine components, etc., can solve problems such as engine damage and valve body 105 falling off, and achieve the effect of smooth injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

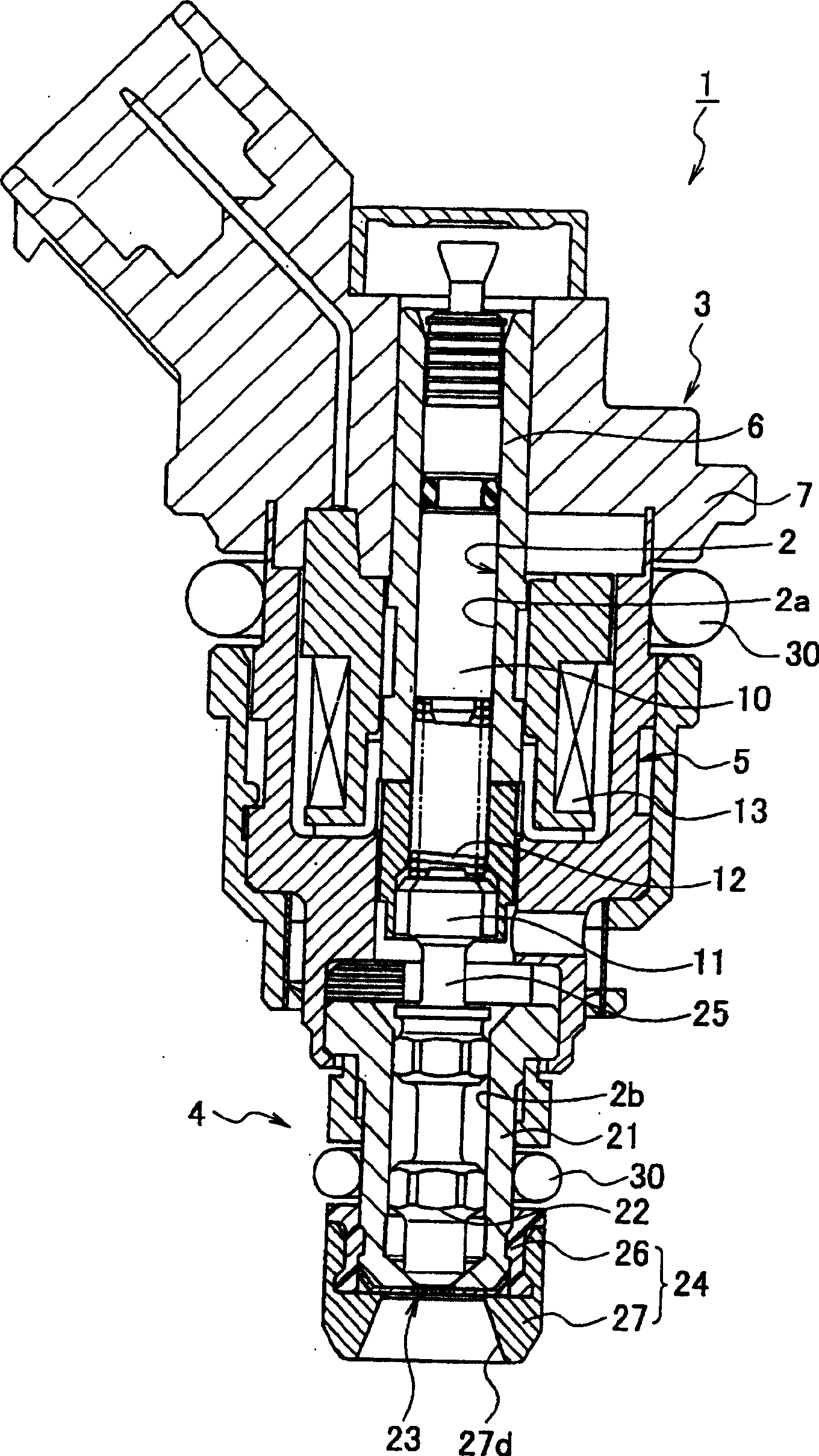

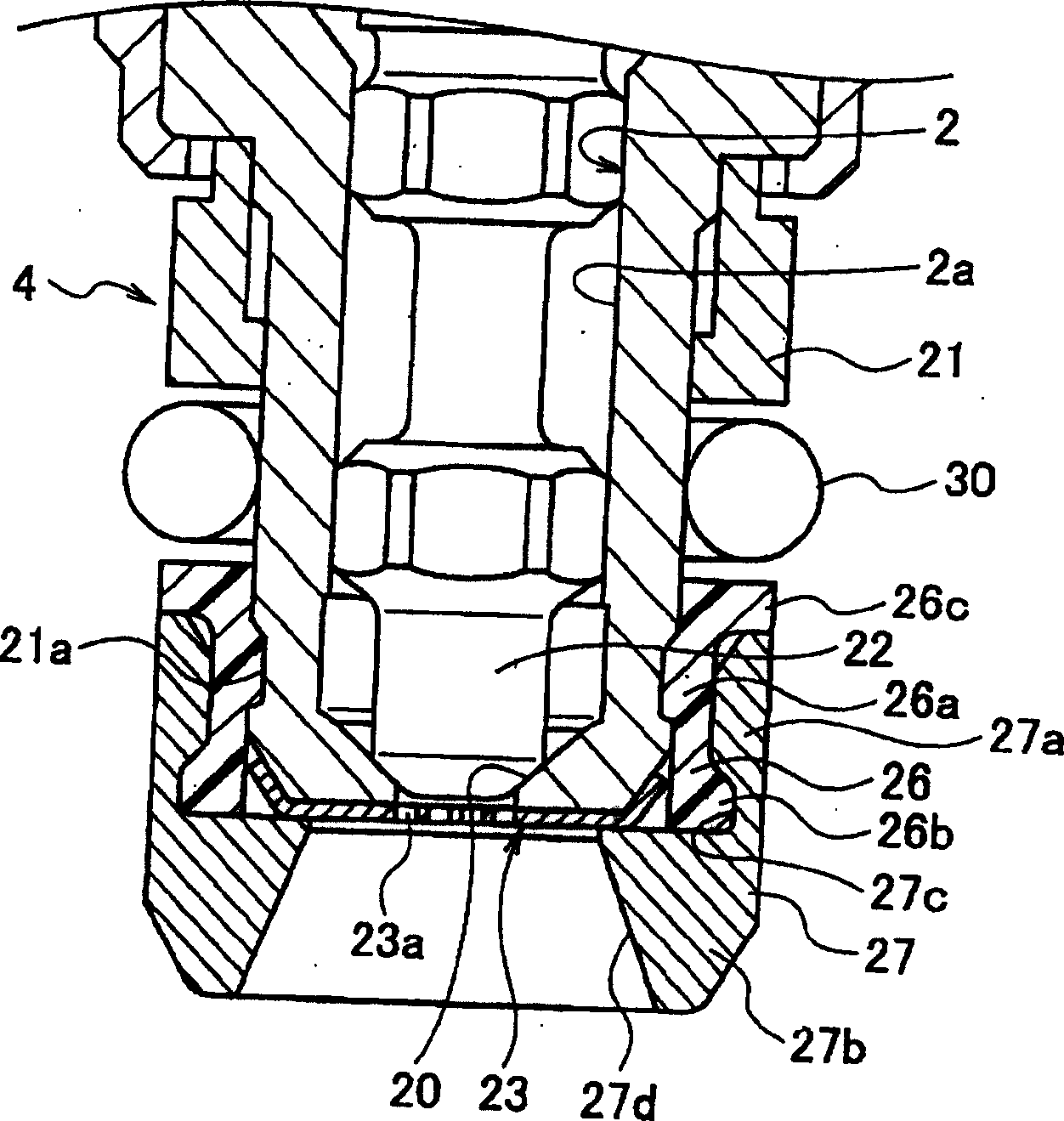

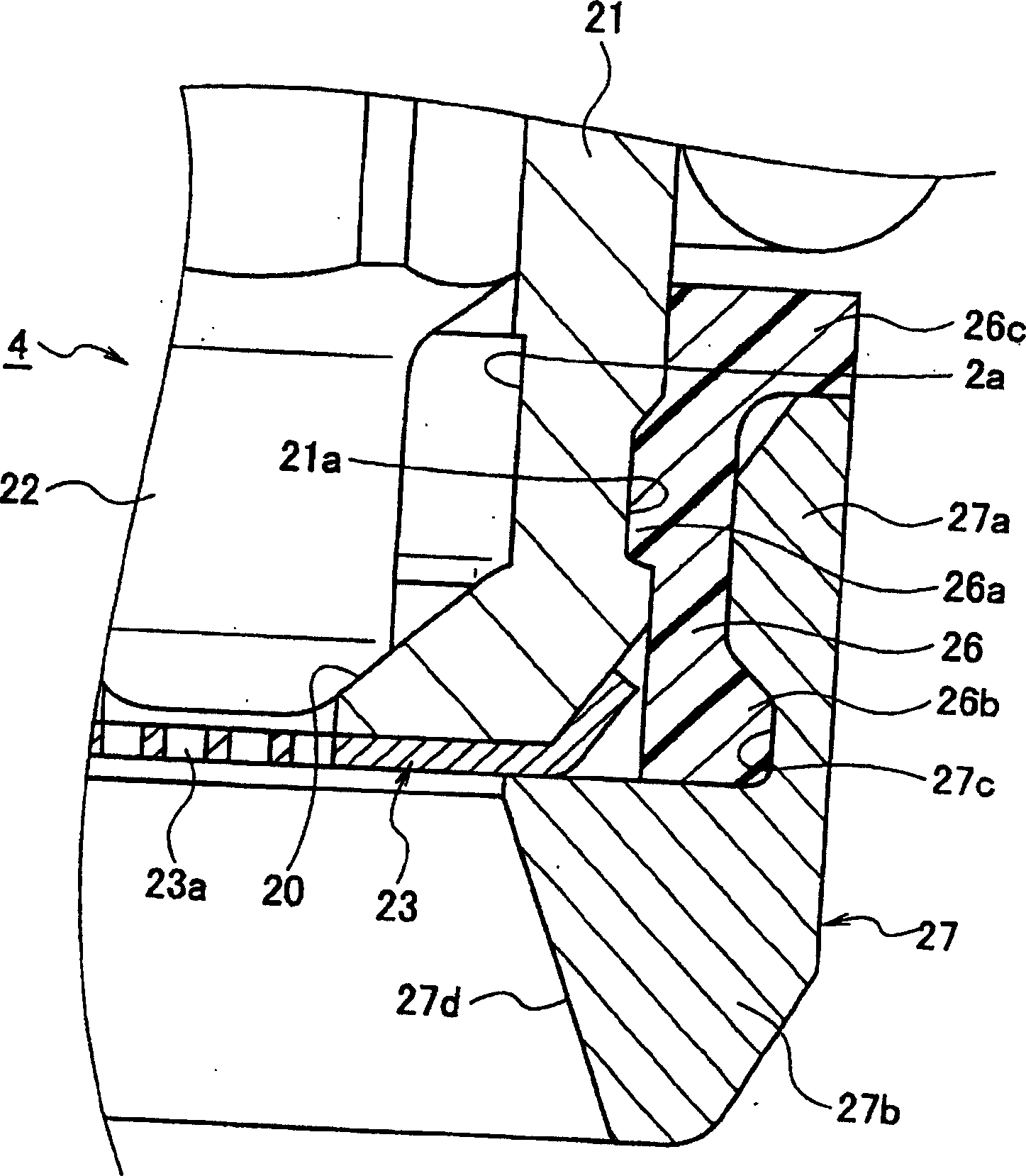

[0025] Hereinafter, an embodiment embodying the present invention will be described with reference to the drawings.

[0026] Figure 1 to Figure 5 represents an embodiment of the present invention, figure 1 is the overall sectional view of the fuel injection valve, figure 2 is a cross-sectional view of the valve mechanism, image 3 It is an enlarged sectional view of the main part of the valve mechanism, Figure 4 is a cross-sectional view of the resin shield part, Figure 5 It is a cross-sectional view of a metal shield component.

[0027] exist figure 1 Among them, the fuel injection valve 1 is provided with a housing 3 in which the upper portion 2a of the fuel flow passage 2 is formed, a valve mechanism 4 for opening and closing the fuel flow passage 2, and the valve mechanism 4 is set between a valve opening position and a valve closing position. Electromagnetic drive for movement5.

[0028] The casing 3 is constructed by assembling a plurality of components such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com