Gasoline engine ignition mechanism comprising pre-combustion chamber with shared jet orifice

A technology of ignition mechanism and pre-combustion chamber, applied in combustion engine, machine/engine, internal combustion piston engine, etc., can solve the problem that the flame of pre-combustion chamber cannot spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

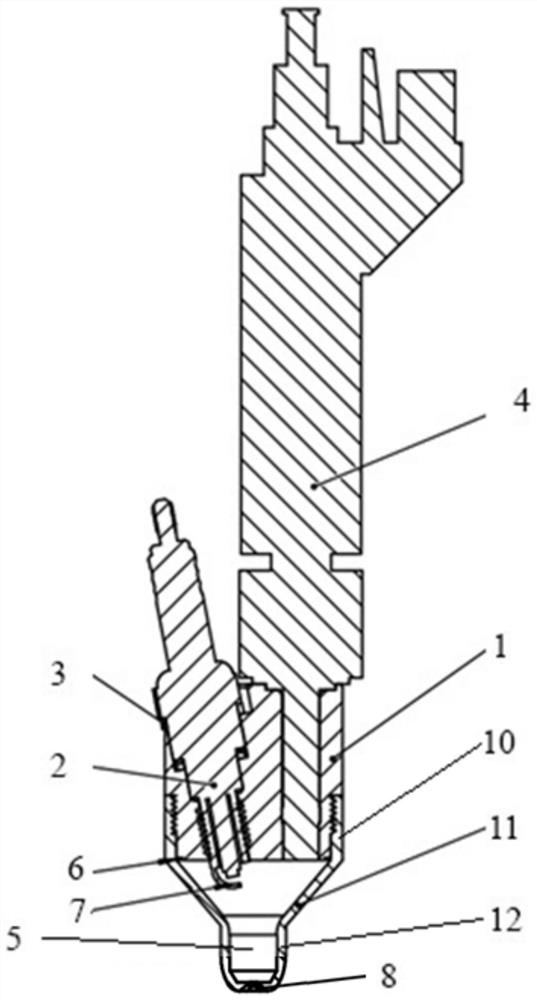

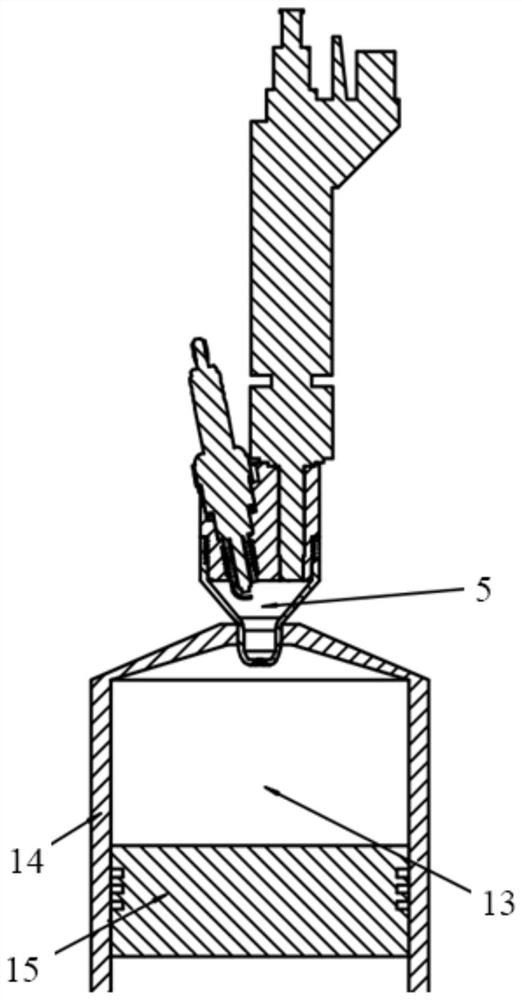

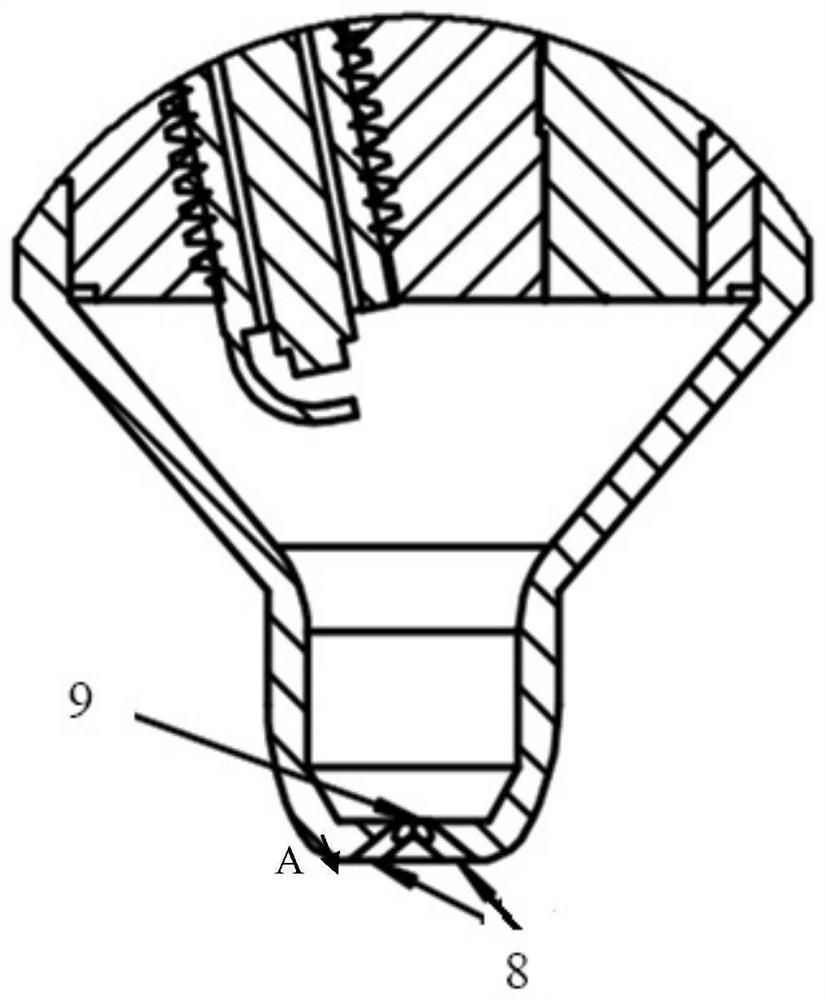

[0015] control attached Figure 1-4 , to illustrate specific embodiments of the present invention.

[0016] An ignition mechanism for a gasoline engine containing a strong tumble pre-combustion chamber, comprising: a cylindrical connecting piece 1, an injector mounting hole penetrating through the upper end surface and the lower end surface of the connecting piece, and a spark plug installation hole penetrating through the upper end surface and the lower end surface of the connecting piece , the pre-combustion chamber 5 connected with the outer peripheral surface of the connector through threads, the pre-chamber injector 4 that works with the injector installation hole, and the pre-chamber spark plug 2 that cooperates with the spark plug installation hole;

[0017] The above-mentioned pre-combustion chamber is composed of three sections, from top to bottom are the first cylindrical casing 10, the conical casing 11 and the second cylindrical cavity 12, the inner diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com