Ultra-high purity hydrogen separator

A separator and ultra-high technology, applied in the field of ultra-high-purity hydrogen separators, to achieve the effect of improving the efficiency and rate of hydrogen separation, simplifying the hydrogen separation system, and having a compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

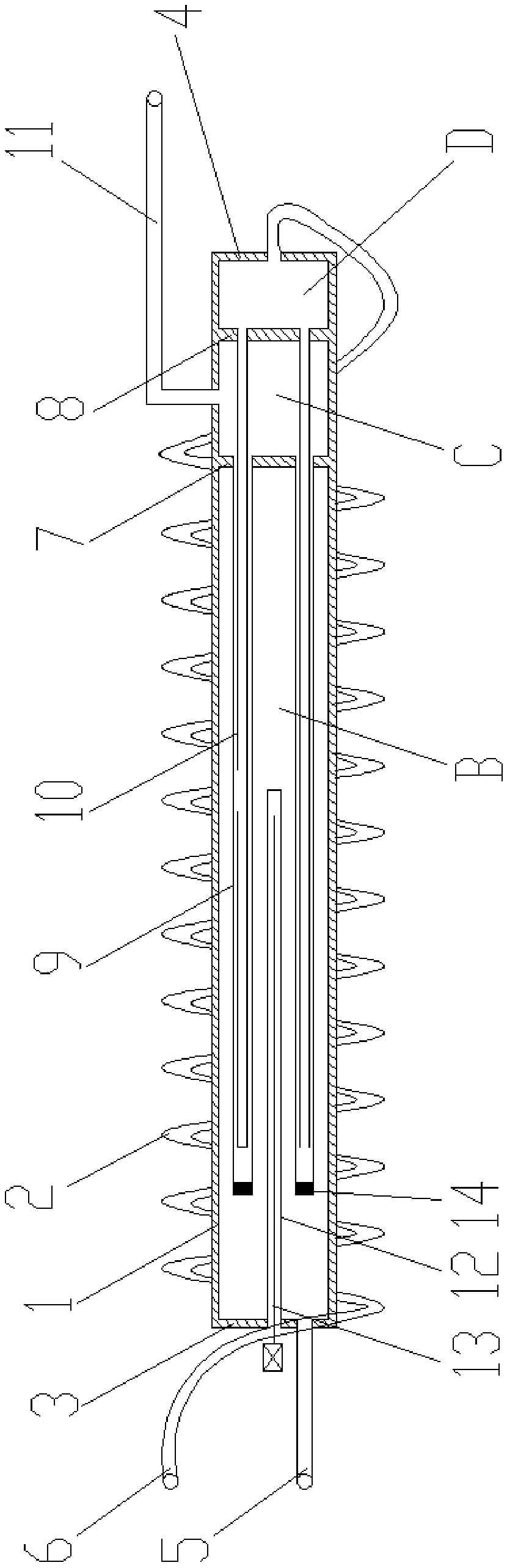

[0030] Such as figure 1 A kind of ultra-high-purity hydrogen separator shown comprises a shell 1 shaped as a circular tube and a coil 2 spirally wound outside the shell 1. One end of the shell 1 is provided with a first plug 3, and the other end is A second plug 4 is provided, the first plug 3 is provided with an ultra-high-purity hydrogen outlet and the outlet is communicated with the ultra-high-purity hydrogen outlet pipe 5, and the second plug 4 is provided with a mixed hydrogen inlet and The inlet is communicated with one end of the coil pipe 2, and the other end of the coil pipe 2 is communicated with the mixed hydrogen inlet pipe 6. In the housing 1, a first baffle plate 7 and a second baffle plate 8 are provided to separate the inside of the housing 1. It is divided into three chambers: a working chamber B, an exhaust gas collecting chamber C, and an intake gas collecting chamber D. The working chamber B is provided with a palladium membrane tube 9 and an inner liner 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com