Fischer-Tropsch synthesis system and method

A Fischer-Tropsch synthesis, qualified technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve problems such as catalyst separation difficulties, and achieve solutions to catalyst fine particle aggregation, scientific design, and flow reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

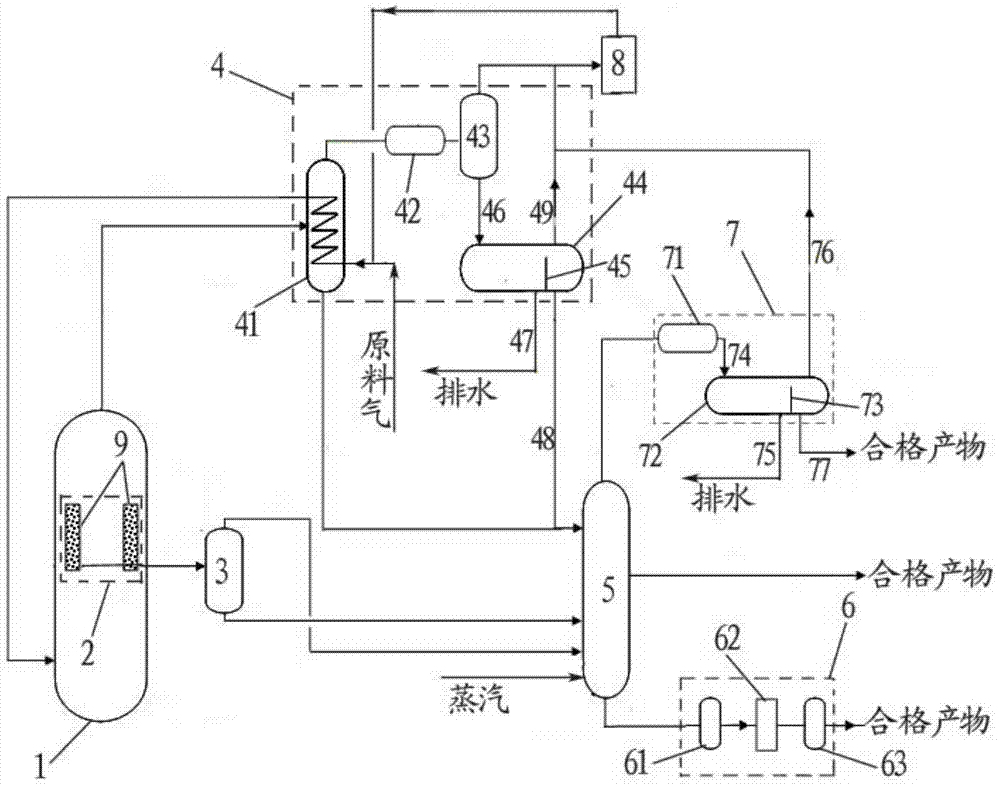

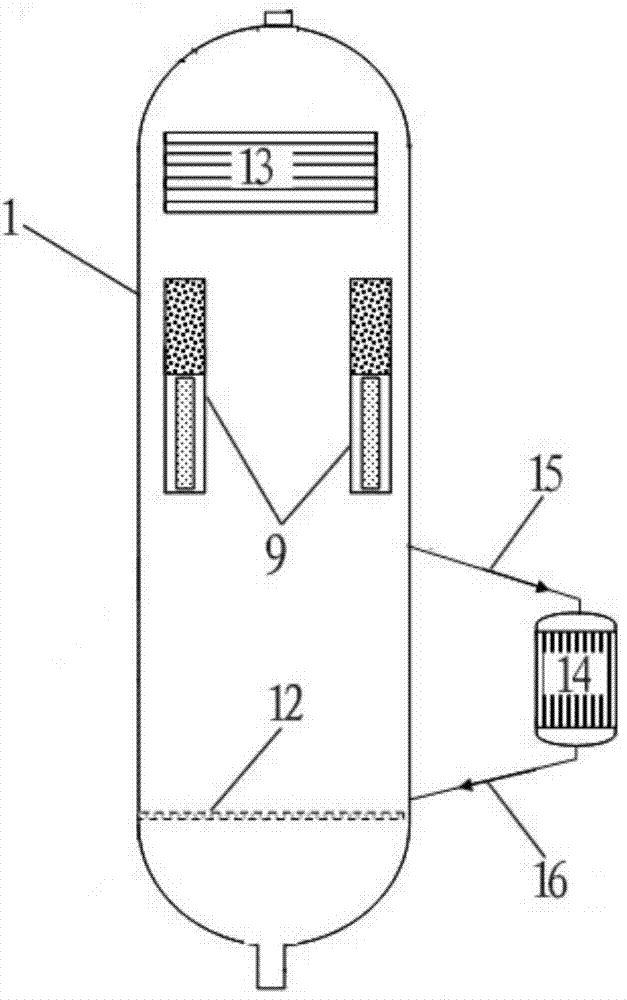

[0043] Such as figure 1 As shown, the Fischer-Tropsch synthesis system with a slurry bed reactor provided by the present invention includes a slurry bed reactor 1 , a first filter device 2 , a first separation device 3 , a second separation device 4 and a stripping column 5 .

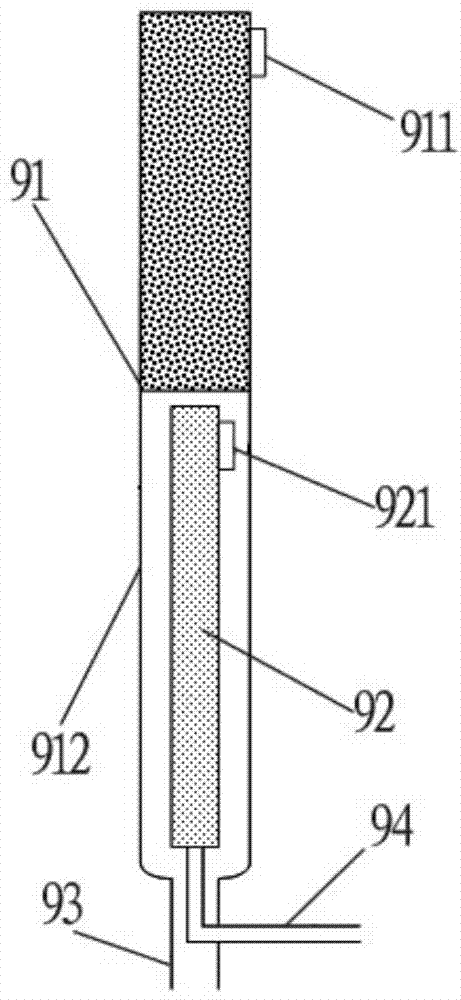

[0044] Wherein, the first filter device 2 is arranged in the slurry bed reactor 1, and is used to filter the catalyst in the liquid phase output to be drawn out of the slurry bed reactor 1, so as to reduce the amount of liquid phase output. The content of large particle catalysts with catalytic activity in the middle. In a preferred embodiment, as figure 2 As shown, the first filter device 2 includes one or more filter pipes 9, and the filter pipe 9 includes an outer filter pipe 91, an inner filter pipe 92, an outer discharge pipe 93 and an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com