Control method for synthesizing ethyl acetate by esterification method

A technology of ethyl acetate and control methods, which is applied in the preparation of organic compounds, chemical instruments and methods, and preparation of carboxylate esters. Effects of reduced consumption, simplified separation system, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, present embodiment provides a kind of control method of synthetic ethyl acetate by esterification method

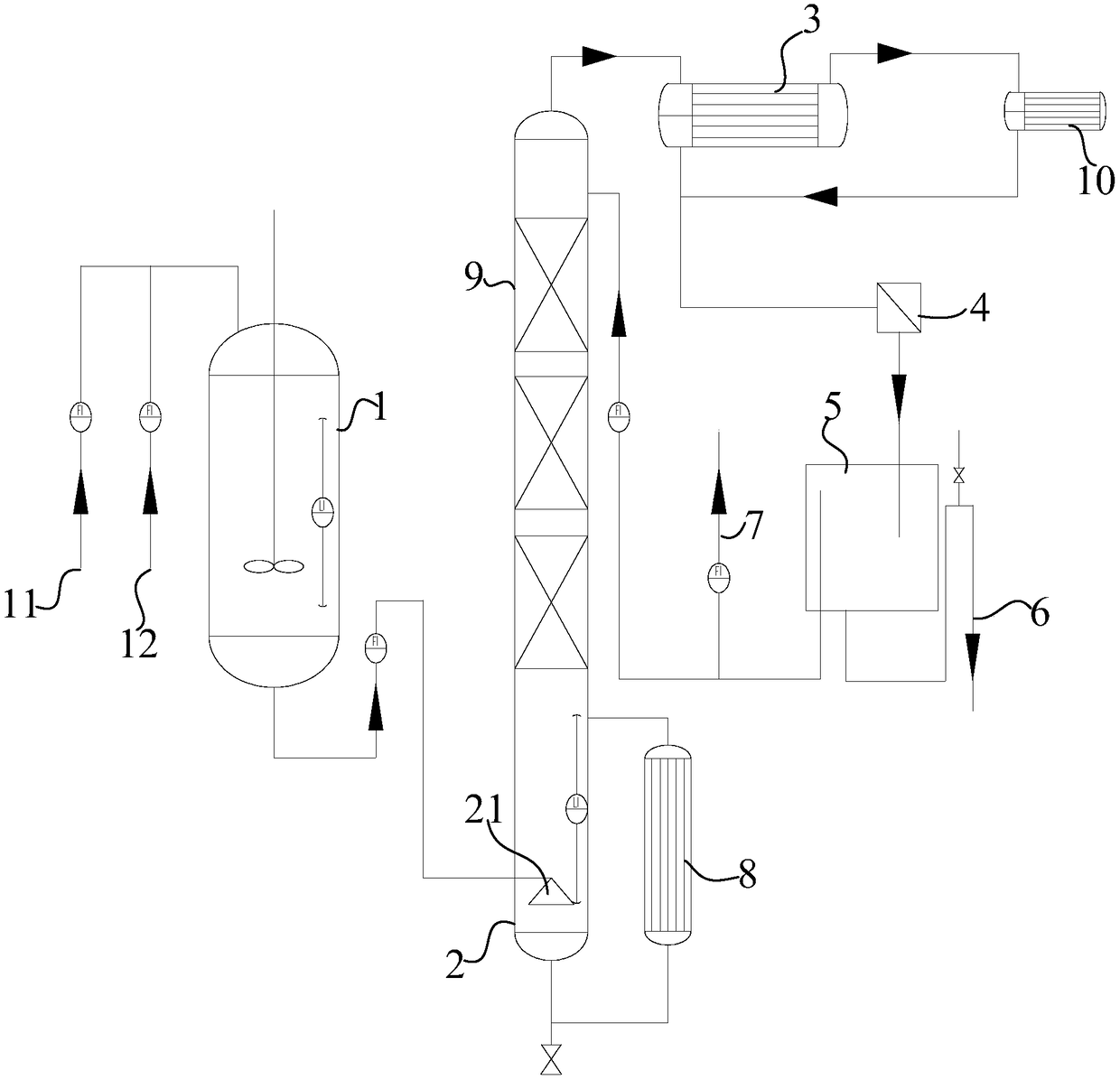

[0027] like figure 1 As shown, the present embodiment first simplifies the system for synthesizing ethyl acetate by the traditional industrial esterification method, removes most of the devices, and retains the necessary mixer 1, esterification tower 2, esterification condenser 3, esterification cooling Device 4 and esterification phase separator 5, mixer 1, esterification tower 2, esterification condenser 3, esterification cooler 4 and esterification phase separator 5 are communicated in sequence through pipelines, and ethanol is set on mixer 1 Inlet 12 and acetic acid inlet 11, the material inlet of the mixer 1 set in the esterification tower 2 should also be set in the lower part of the esterification tower 2, specifically above the distributor 21, and enter the esterification tower 2 from the mixer 1 The material, after being distributed by the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com