Continuous flow intermittent aeration type biological film nitrogen and phosphorus removal device and method

A biological aeration, nitrogen and phosphorus removal technology, applied in the field of sewage treatment, can solve the problems of high cost of sludge treatment, large amount of residual sludge, long process chain, etc., to improve the utilization rate of carbon sources, high degree of automation, The effect of a short process chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

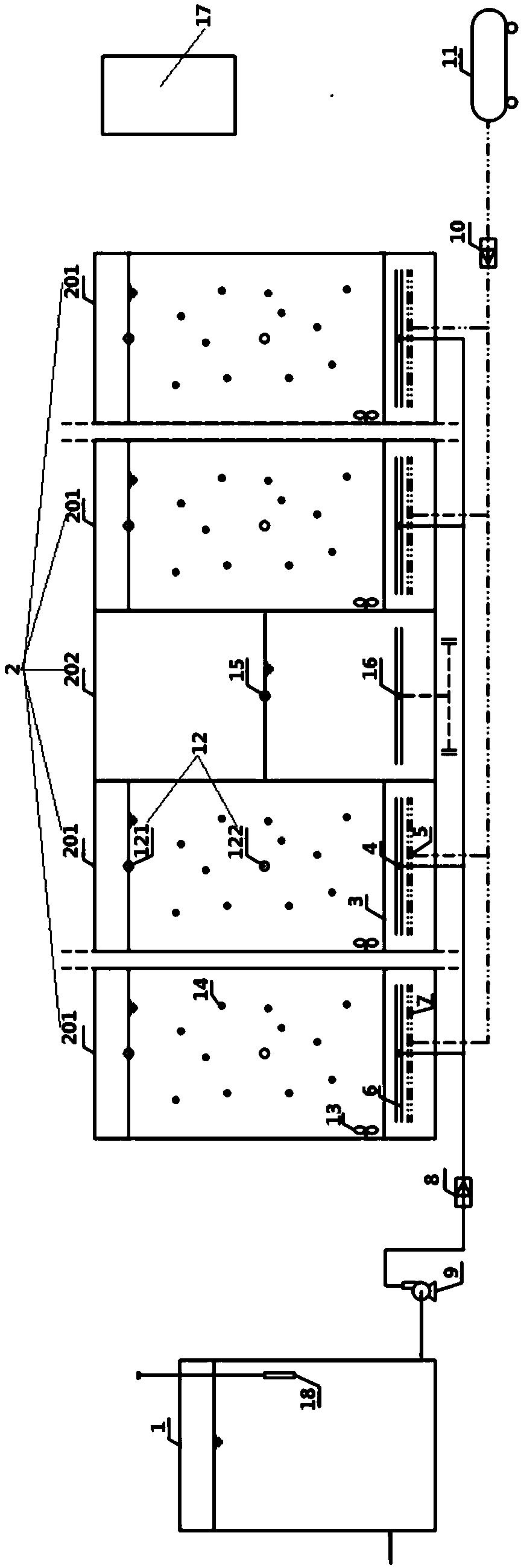

[0063] This embodiment adopts a continuous flow intermittent aeration biofilm denitrification and phosphorus removal device, as attached figure 1 As shown, it includes a regulating tank 1 connected in sequence, and an integrated reactor 2. The reactor 2 includes a plurality of reaction zones 201 and a water outlet zone 202. A porous partition 3 is horizontally arranged in the reaction zone 201.

[0064] The interior of the reaction zone 201 is located below the porous partition 3 and is provided with a reaction zone water inlet 4 and a reaction zone air inlet 5. The reaction zone water inlet 4 is provided with a water distribution mechanism 6, and the reaction zone air inlet 5 is provided with a Valve train 7. The water inlet 4 of the reaction zone is connected to the liquid flow meter 8, the water inlet pump 9, and the regulating tank 1 in sequence through the pipeline, and the air inlet 5 of the reaction zone is connected to the air flow meter 10 and the blowing device 11 in...

Embodiment 2

[0082] The continuous flow intermittent aeration biofilm denitrification and phosphorus removal device used in this example is the same as that in Example 1. The difference from Embodiment 1 is that each reaction zone 201 of the reactor 2 described in this embodiment adopts the intermittent operation cycle variable water level operation mode. The operation method and process of the device are as follows:

[0083] The reactor 2 can realize continuous water inflow and continuous water outflow. The reaction zone 201 adopts a sequential batch operation mode, including water inflow, reaction, standing, water outflow and other processes. The intelligent control system 17 controls the operation of the device.

[0084] Sewage is introduced into the adjustment tank 1 to balance the water quality and quantity, and the effluent from the adjustment tank 1 is introduced into the reactor 2 . During the water intake process, the control valves of the water inlet 4 of the reaction zone from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com