CO2-trapping spray device and technology

A technology of spray device and nozzle device, which is applied to the separation of dispersed particles, air quality improvement, chemical instruments and methods, etc., and can solve problems such as uneven spatial distribution and reduced capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

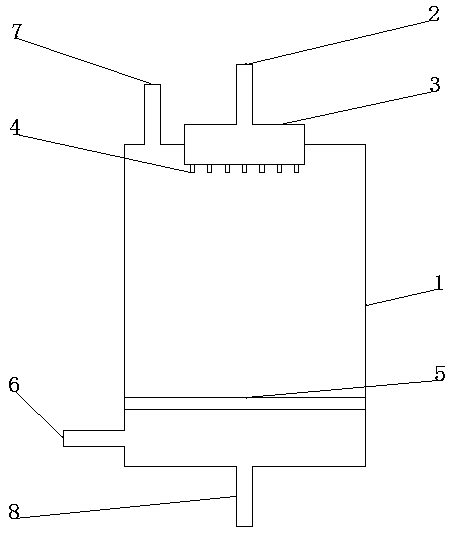

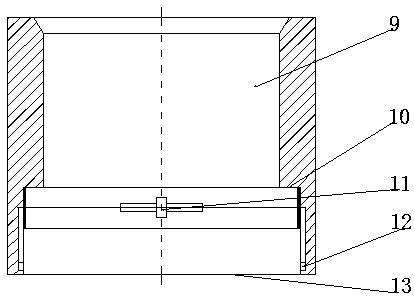

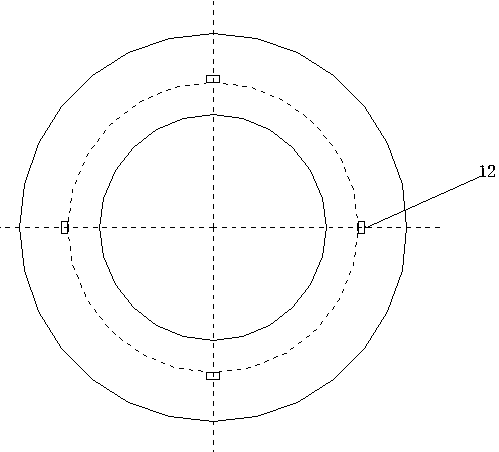

[0027] like Figure 1~6 As shown, a CO capture 2 The spraying device comprises a spray tower, and the top of the spray tower body 1 is provided with a liquid inlet 2 and a gas outlet 7, and the bottom is provided with a liquid outlet 8 and an air inlet 6, and a gas distributor 5 is arranged above the air inlet 6 , the liquid inlet 2 is connected to the liquid reservoir 3, the liquid reservoir 3 is connected to the nozzle device 4, and the nozzle device 4 is composed of nozzle units arranged in an orderly manner, and each nozzle unit is composed of a double-layer nozzle plate, a rotary drive assembly 11 and a pressure sensor 12; the double-layer nozzle plate includes a nozzle front plate 13 and a nozzle rear plate 10, and nozzle holes are uniformly arranged on the nozzle front plate 13 and the nozzle rear plate 10; the rotary drive assembly 11 includes a rotary core 14 and a rotating ring 15, The rotary core 14 is equipped with an electromagnetic induction device; the rotary d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com