Reactor for treating village and town sewage based on aerobic granular sludge and sewage treatment method

An aerobic granular sludge and reactor technology, which is applied to the adjustment method of biological treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of low intelligence of monitoring equipment and denitrification The efficiency of phosphorus removal is not high enough, the design and operation capacity of sewage treatment facilities is too large, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

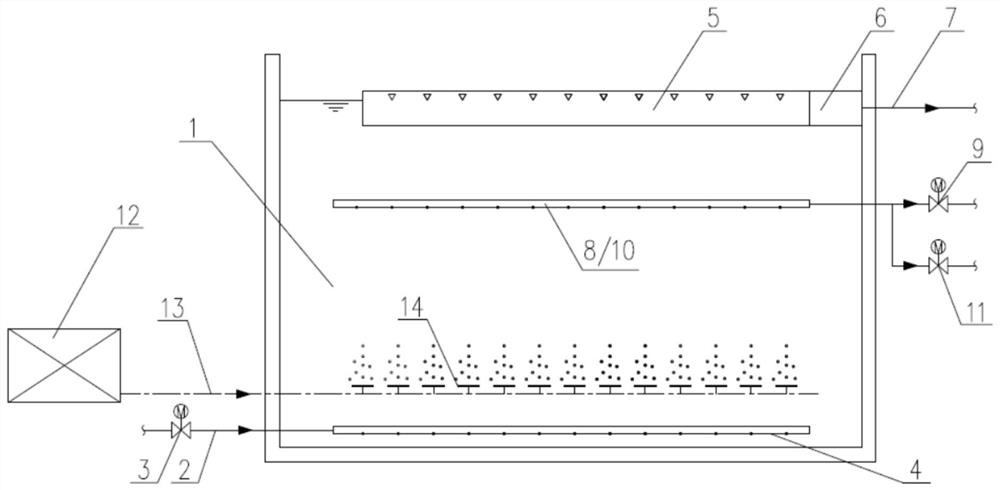

[0054] This example relates to a reactor based on aerobic granular sludge treatment of village and town sewage, see attached figure 1 , 2 Shown:

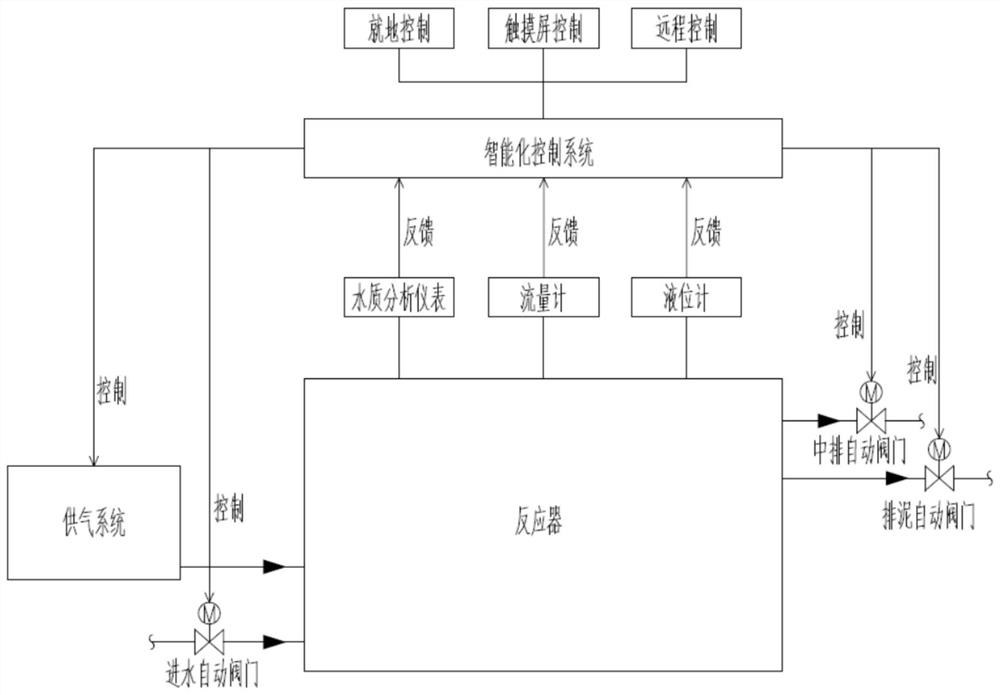

[0055] A reactor for treating sewage in villages and towns, including: a water inlet system, a drainage system, a middle drainage system, a mud discharge system, an aeration system and an intelligent control system;

[0056] The water inlet system includes: a water inlet pipe 2, an automatic water inlet valve 3, and a water distribution pipe 4 arranged at the bottom of the reactor;

[0057] The drainage system includes: an outlet weir 5, an outlet channel 6, and an outlet pipe 7 arranged at the top of the reactor;

[0058] The middle row system includes: a middle row pipeline 8 and a middle row automatic valve 9 arranged in the middle of the reactor;

[0059] The sludge discharge system includes: a sludge discharge pipeline 10 and an automatic sludge discharge valve 11 arranged in the middle of the reactor;

[0060] The aeration...

Embodiment 2

[0068] This example relates to a reactor based on aerobic granular sludge treatment of village and town sewage, see attached figure 1 , 2 Shown:

[0069] A reactor for treating village and town sewage based on aerobic granular sludge, including: water intake system, drainage system, middle drainage system, sludge discharge system, aeration system and intelligent control system;

[0070] The water inlet system includes: a water inlet pipe 2, an automatic water inlet valve 3, and a water distribution pipe 4 arranged at the bottom of the reactor;

[0071] The drainage system includes: an outlet weir 5, an outlet channel 6, and an outlet pipe 7 arranged at the top of the reactor;

[0072] The middle row system includes: a middle row pipeline 8 and a middle row automatic valve 9 arranged in the middle of the reactor;

[0073] The sludge discharge system includes: a sludge discharge pipeline 10 and an automatic sludge discharge valve 11 arranged in the middle of the reactor;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com