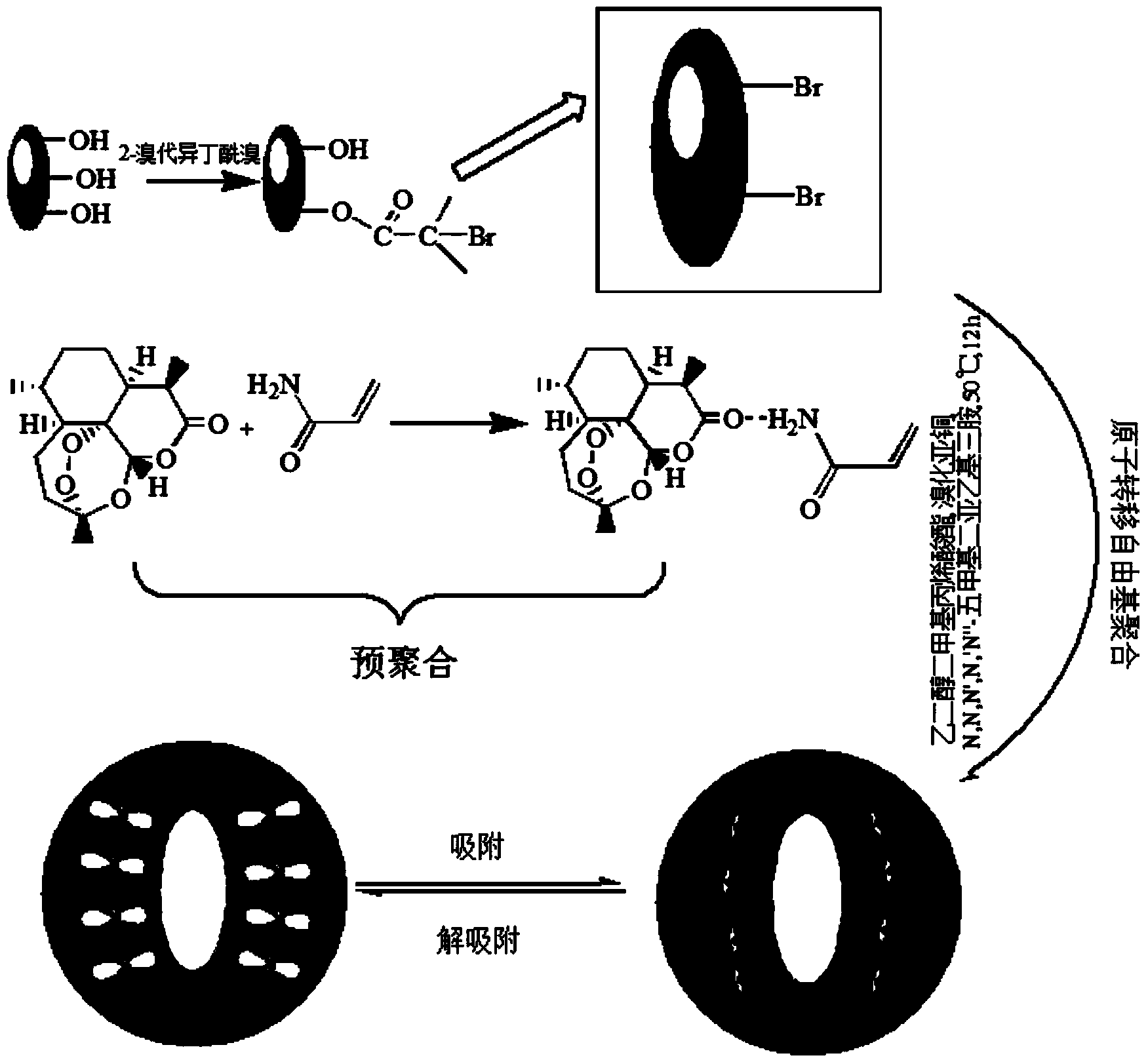

Preparation method and application of arteannuin molecularly imprinted membrane

A molecularly imprinted membrane, molecularly imprinted technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve high selectivity, significant separation effect, and repeated use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Purification of regenerated cellulose membrane surface

[0039] Take a piece of regenerated cellulose membrane and place it in 100ml of methanol, let it stand at room temperature for 30 minutes, wash it thoroughly with deionized water, and dry it in a vacuum oven at 60°C to constant weight.

[0040] (2) Atom transfer-based polymerization initiator fixed on the surface of regenerated cellulose membrane

[0041]Add 1 mL of bromoisobutyryl bromide (2-BIB) to 15 mL of refined tetrahydrofuran, mix well and add to the dropping funnel for later use. Place the regenerated cellulose membrane in a 100 mL three-neck round bottom flask, add 25 mL Refined tetrahydrofuran and 1 mL of dry triethylamine, shaken at 0°C and blown nitrogen gas for 30 min, added the above 2-BIB solution dropwise, and kept at 0°C for 2 h, took out the flask, and sealed it with paraffin after 25 Continue to shake the reaction for 24 h at ℃, take out the membrane after the reaction, wash thoroughly with ...

Embodiment 2

[0052] (1) Purification of regenerated cellulose membrane surface

[0053] A piece of regenerated cellulose membrane was placed in methanol, and after standing at room temperature for 30 min, it was fully washed with deionized water, and dried in a vacuum oven at 60 °C to constant weight.

[0054] (2) Atom transfer-based polymerization initiator fixed on the surface of regenerated cellulose membrane

[0055] Add 1 mL of bromoisobutyryl bromide (2-BIB) to 15 mL of refined tetrahydrofuran, mix well and add to the dropping funnel for later use. Place the regenerated cellulose membrane in a 100 mL three-neck round bottom flask, add 25 mL Refined tetrahydrofuran and 1 mL of dry triethylamine, shaken at 0°C and blown nitrogen gas for 30 min, added the above 2-BIB solution dropwise, and kept at 0°C for 2 h, took out the flask, and sealed it with paraffin after 25 Continue to shake the reaction for 24 h at ℃, take out the membrane after the reaction, wash thoroughly with tetrahydrofu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com