Welding clamping fixture for midpiece of monocoque bus frame

A full-load, frame technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of inconvenient adjustment of welding tires in the middle of the frame, and achieve high cost, high production efficiency, The effect of shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

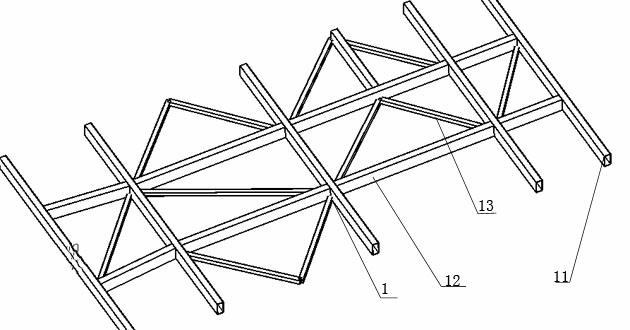

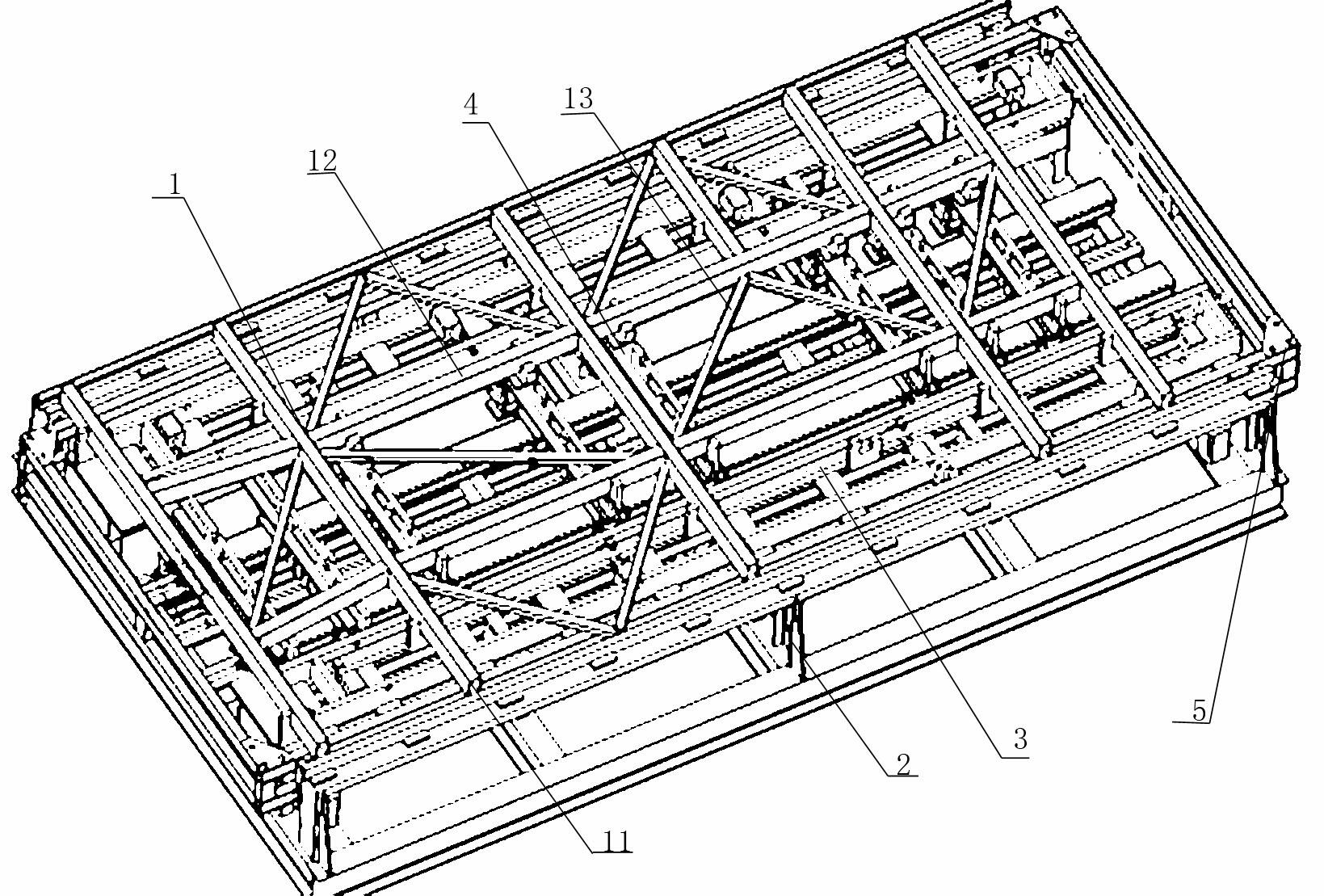

[0016] The embodiment of the welded mold in the middle section of the frame of the full-loaded passenger car: as Figure 1 to Figure 4 As shown, the welding tire is mainly composed of the underframe 2, the longitudinal beam positioning device 4 for positioning the frame 1 longitudinal beam 12 and the brace 13, and the beam positioning device 3 for positioning the vehicle frame 1 beam 11.

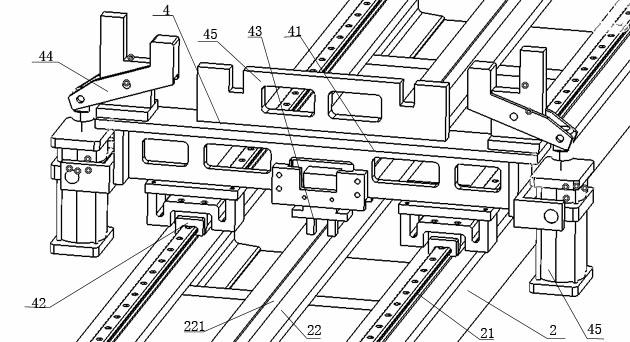

[0017] Wherein, two guide rails 21 are arranged on the underframe 2, and there are eight longitudinal beam positioning devices 4 and are all perpendicular to the guide rails 21. The main body of the longitudinal beam positioning device is composed of a bracket 41, and the bottom of the bracket 41 is provided with a Along the lengthwise direction of the guide rail 21 is a sliding block 42 that is guided and matched. A pneumatic finger 43 for locking the longitudinal beam positioning device on the chassis 2 is arranged between the two sliding blocks 42, and the chassis 2 is positioned on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com