Methods and apparatus for assembling and operating semi-monocoque rotary machines

A semi-hard shell, shell technology, applied in mechanical equipment, engines, wind turbines, etc., can solve problems such as increasing infrastructure costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

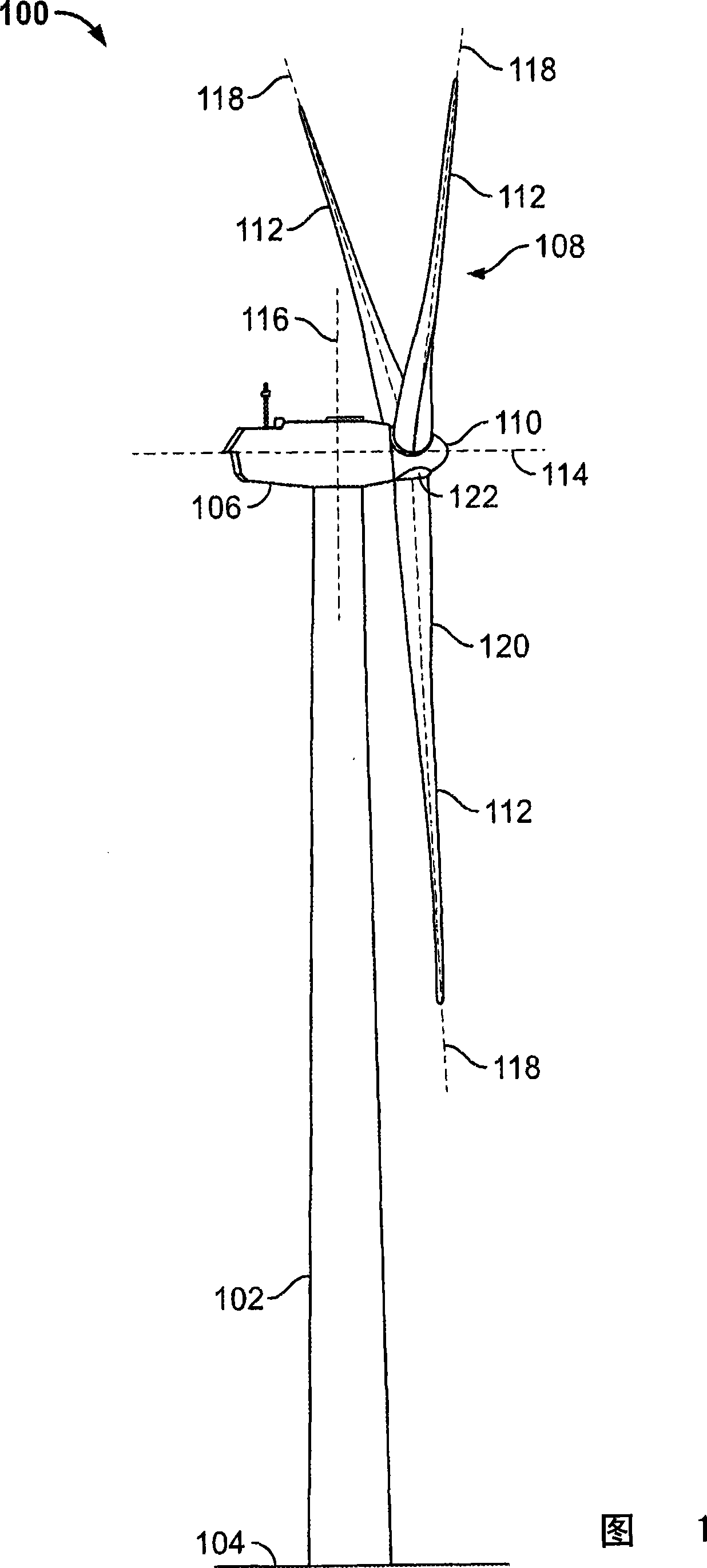

[0013] FIG. 1 is a schematic diagram of a typical wind turbine generator 100 . In a typical embodiment, wind turbine generator 100 is a horizontal axis wind turbine. Alternatively, wind turbine 100 may be a vertical axis wind turbine. Wind turbine 100 has a tower 102 extending from a support surface 104 , a nacelle 106 mounted on tower 102 , and a rotor 108 mounted on nacelle 106 . Rotor 108 has a rotatable hub 110 and a plurality of rotor blades 112 mounted to hub 110 . In the exemplary embodiment, rotor 108 has three rotor blades 112 . In alternative embodiments, the rotor 108 may have more or less than three rotor blades 112 . In a typical embodiment, tower 102 is made of steel pipe with a cavity (not shown in FIG. 1 ) extending between support surface 104 and nacelle 106 . In an alternative embodiment, the tower 102 is a lattice tower. The height of tower 102 is selected according to factors and conditions known in the art.

[0014] Blades 112 are positioned about ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com