Boiler for generating power by combusting exhausting gas of yellow phosphorus

A technology for power generation boilers and yellow phosphorus tail gas is applied in the field of power generation boilers and yellow phosphorus tail gas power generation boilers, which can solve the problems of large heating area, large volume of waste heat boilers, and large heat dissipation losses of adiabatic combustion furnaces, saving energy resources, The setting is compact and the effect is favorable for environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

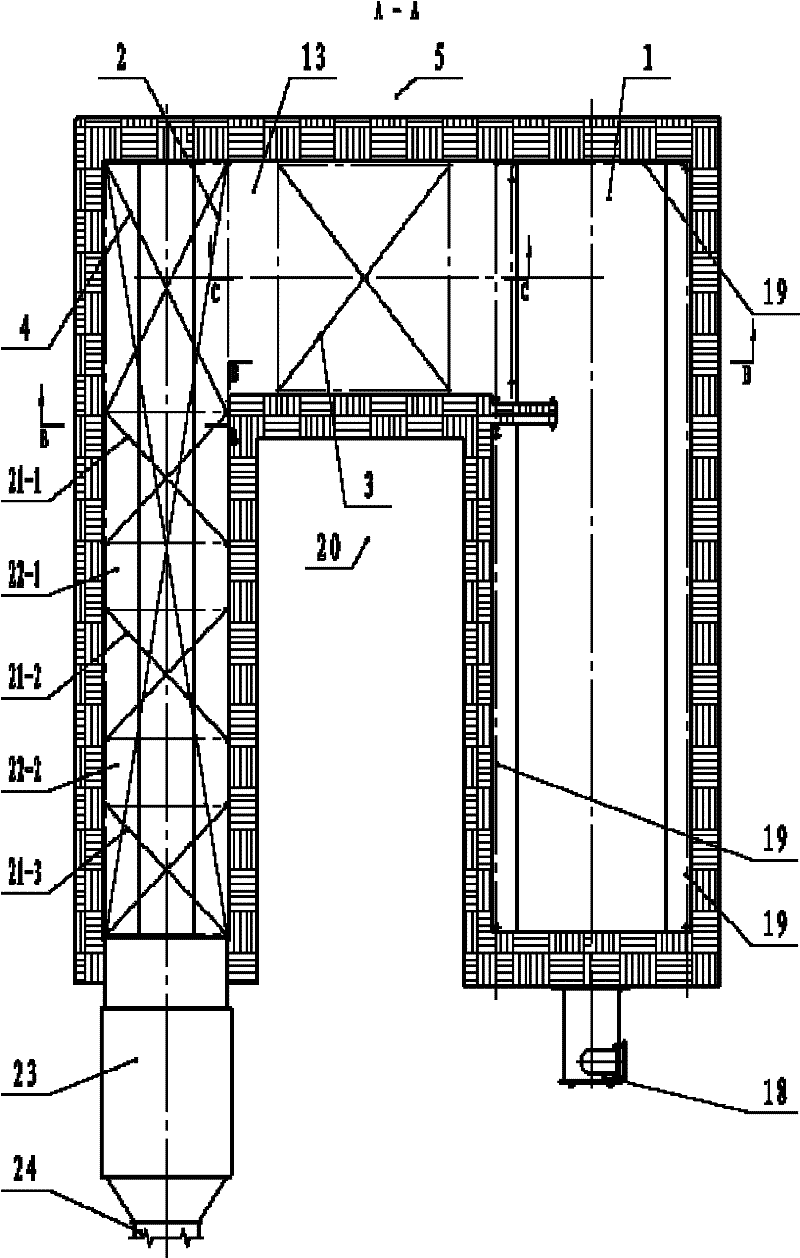

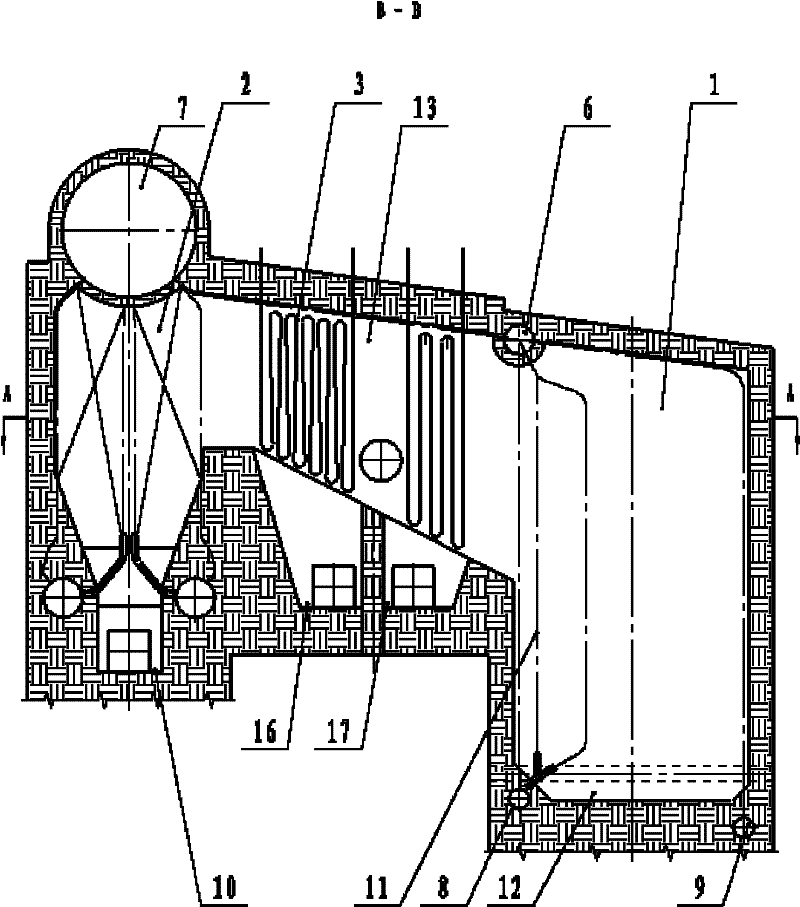

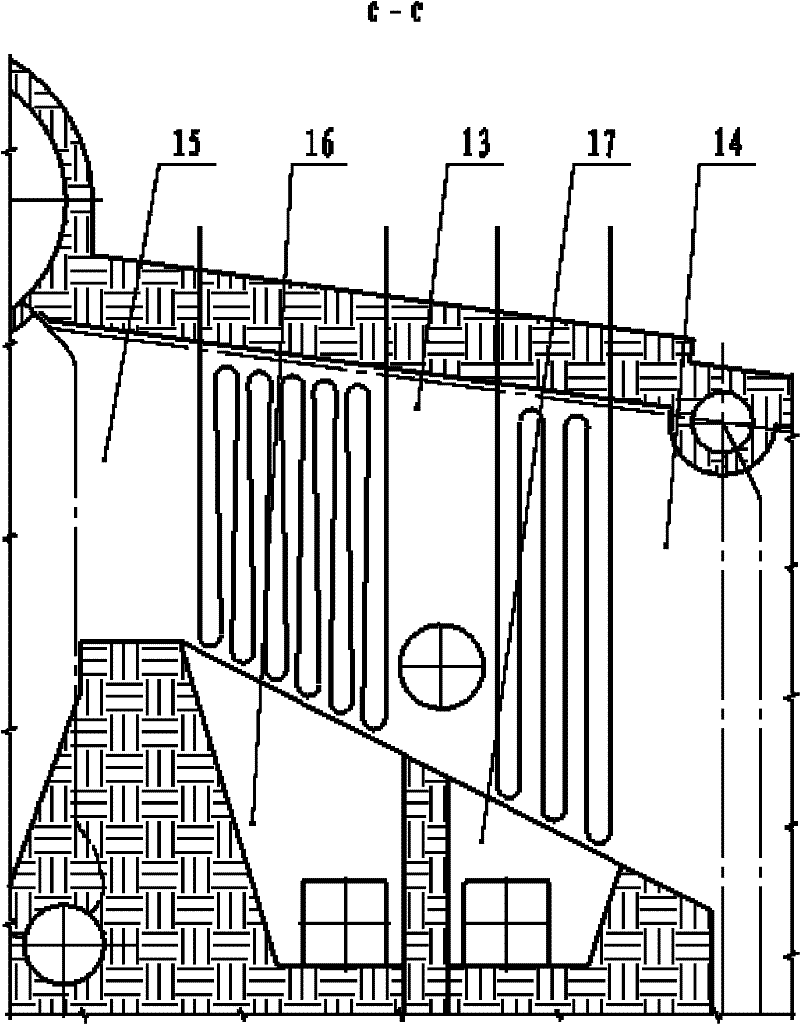

[0020] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

[0021] The present invention includes that the boiler body is generally arranged in a horizontal "∏" shape, that is, the furnace 1 is on the right side, and the boiler tube bundle 2 is on the left side; , the center line of the superheater 3 is perpendicular to the center line of the furnace 1 and the boiler tube bundle 2; there is an inspection channel 20 between the furnace 1 and the boiler tube bundle 2 and in front of the superheater 3, and there is an inspection space 5 behind the superheater 3.

[0022] The left and right side walls and the rear wall of the furnace 1 are provided with a water-cooled wall 19 and a furnace outlet pipe group 11, and the lower part is provided with a dust accumulation pit 12; the upper headers 6 of the left and right water-cooled walls are lower than the bottom of the drum 7. The pipes of the water wall 19 and the header 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com