Gantry sucker automatic loading system

A technology of automatic feeding and suction cups, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, boring and tedious work, etc., and achieve the effect of solving high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

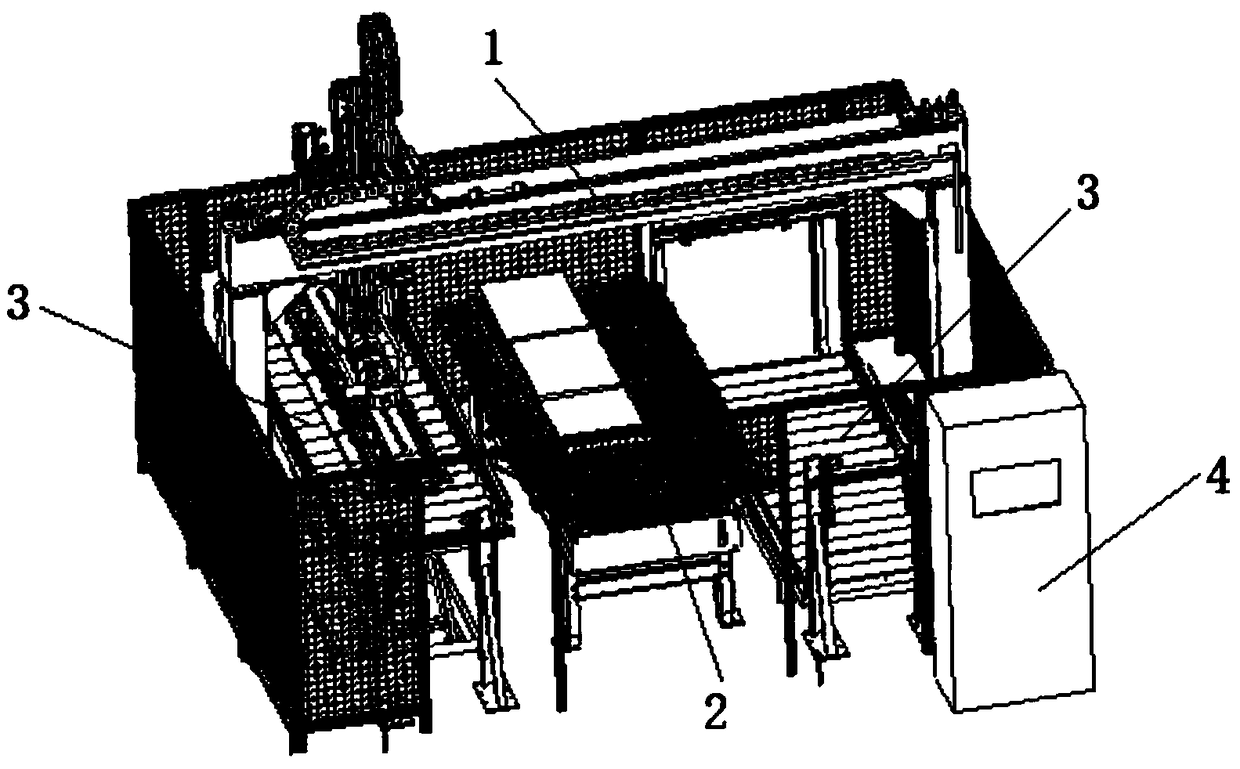

[0045] A gantry suction cup automatic feeding system provided in this embodiment has a structure such as figure 1 As shown, it includes a gantry suction cup transfer machine 1, a belt roller combined vertical and horizontal translation machine 2, two hydraulic lifting roller machines 3 and a control system 4, the belt roller combined vertical and horizontal translation machine 2 is located in the middle, and the hydraulic lifting roller machine 3 They are arranged on both sides of the belt-drum combined vertical and horizontal translation machine 2. The gantry suction cup transfer machine 1 spans above the belt-drum combined vertical and horizontal translation machine 2 and the hydraulic lifting roller machine 3. The gantry suction cup transfer machine 1 and the belt roller Both the combined vertical and horizontal translation machine 2 and the hydraulic lifting roller machine 3 are controlled by the control system 4 .

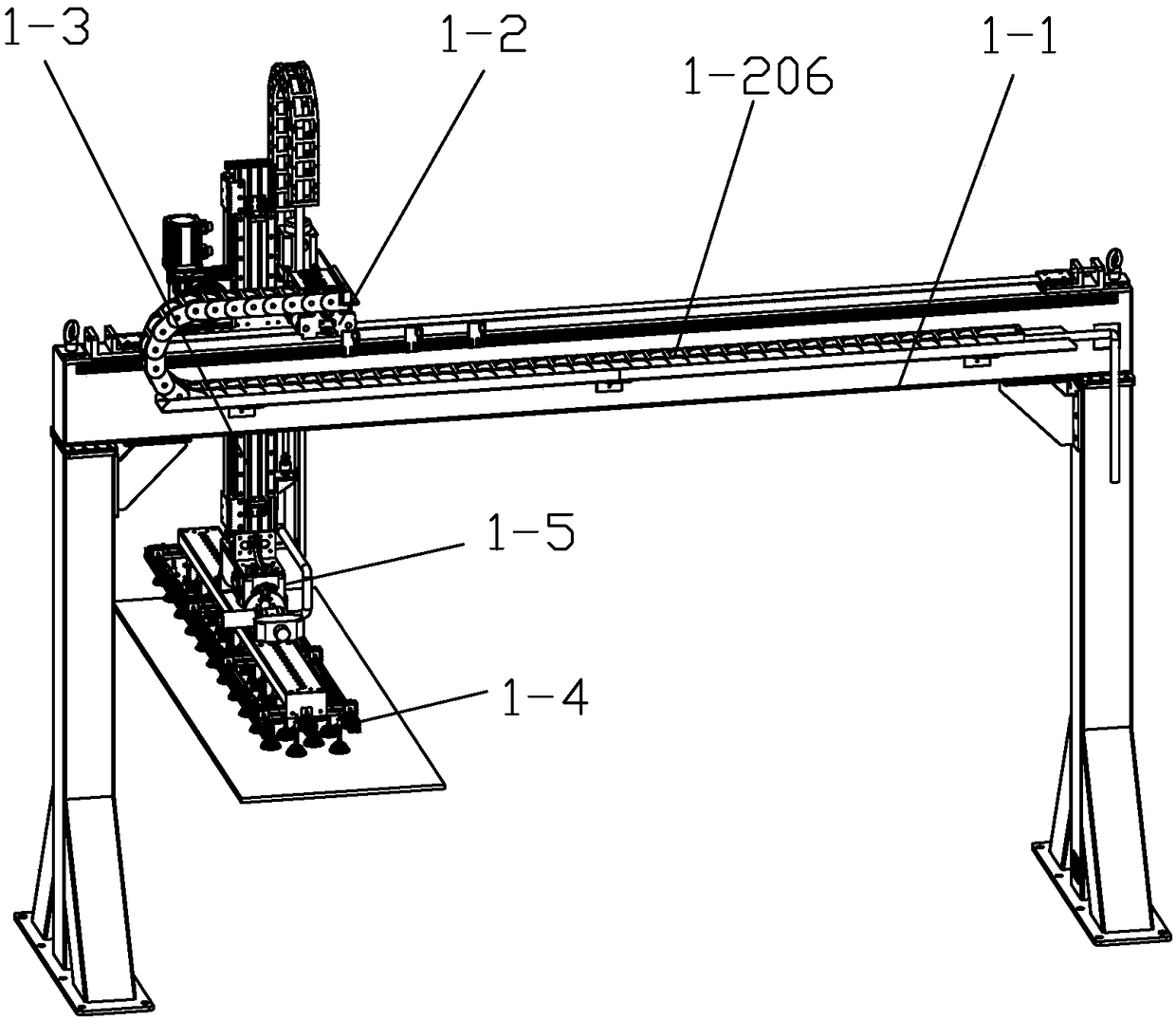

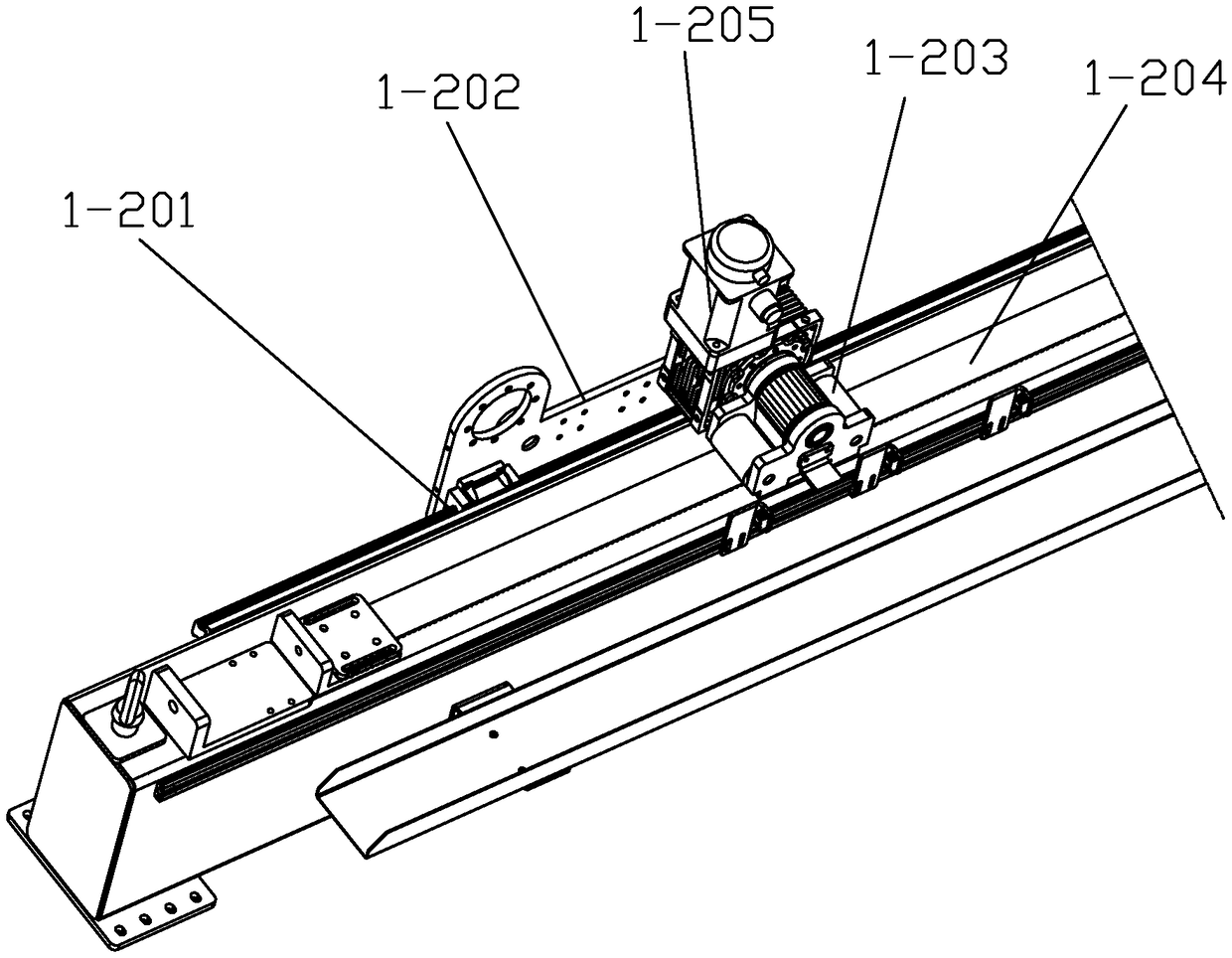

[0046] like figure 2 As shown, the gantry type suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com