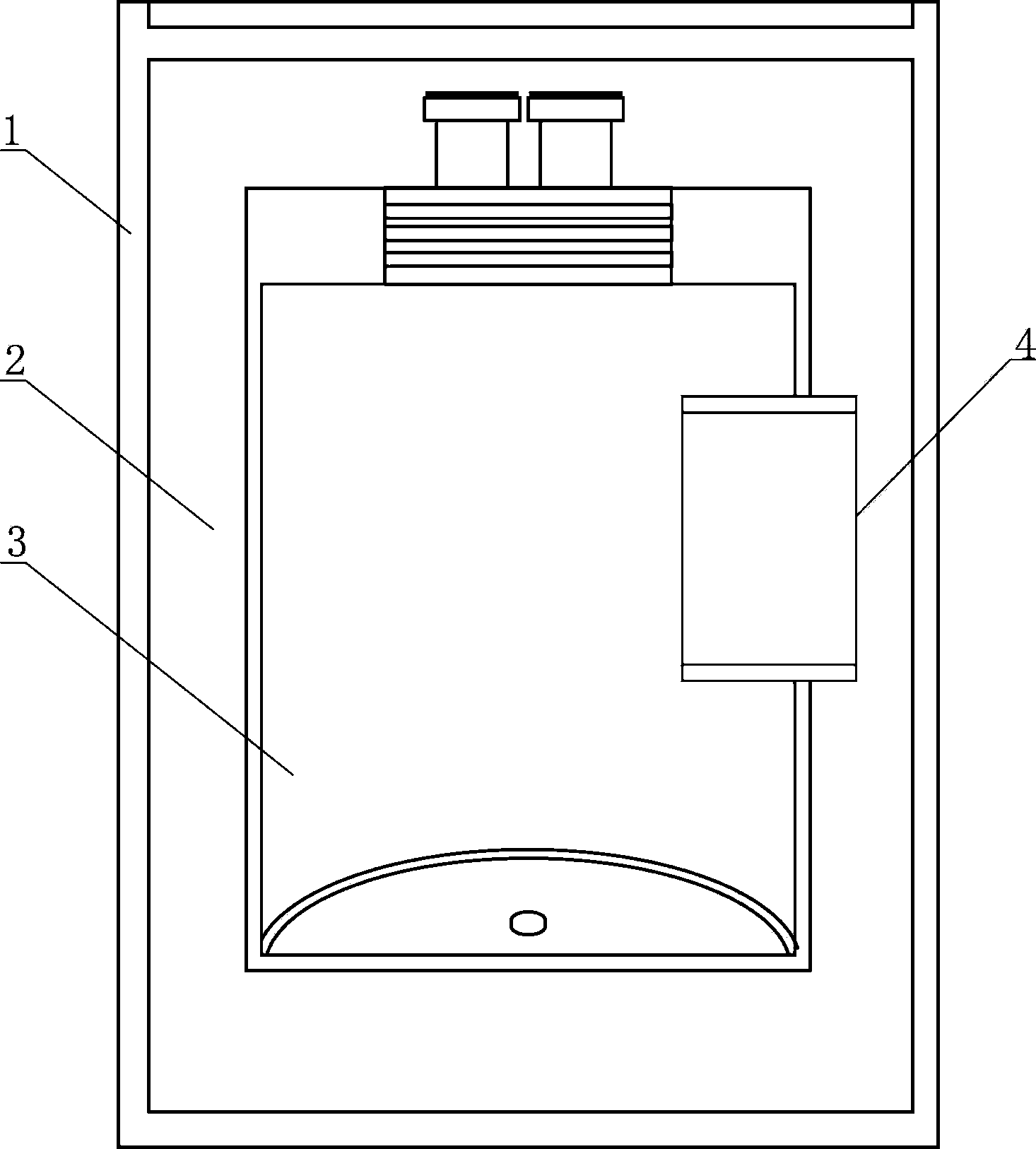

Vacuum leak-detection sterile dual-valve soft bag transfusion combined bag

A soft bag infusion and vacuum technology, applied in the field of infusion combined infusion soft bag packaging, can solve the problems of visual fatigue, prone to errors, waste of production resources, etc., to reduce visual fatigue, reduce the probability of leaving the factory, and save production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of air leak detection aseptic double-valve soft bag transfusion combination bag of the present invention is made according to the following process:

[0041] (1) The packaging material film enters the workshop: take out the material film used for the liquid medicine bag from the package, put it in a sterilizer for high-pressure and high-temperature sterilization, and the sterilization temperature is 121°C, and the sterilization pressure is 0.5MPa. The sterilization time is 10 minutes; then it is made into an inner package and enters the liquid medicine filling workshop. The inner packaging is made by welding, including cutting, welding, and adding double-valve infusion ports.

[0042] The material film used for the outer packaging bag is folded out of the package and directly enters the outer packaging packaging workshop.

[0043] (2) The inner packaging is filled with liquid medicine to form a soft bag for infusion, which is then sterilized and dried. The medici...

Embodiment 2

[0048] The air leak detection aseptic double-valve soft bag transfusion combination bag of the present invention is prepared according to the following process:

[0049] (1) The packaging material film enters the workshop: take out the material film used for the liquid medicine bag from the package, put it in a sterilizer for high-pressure and high-temperature sterilization, and the sterilization temperature is 121°C, and the sterilization pressure is 0.5MPa. The sterilization time is 10 minutes; then it is made into an inner package and enters the liquid medicine filling workshop. The inner packaging is made by welding, including cutting, welding, and adding an infusion port.

[0050] The material film used for the outer packaging bag is folded out of the package and directly enters the outer packaging packaging workshop.

[0051] (2) The inner packaging is filled with liquid medicine to form a soft bag infusion, and then sterilized and dried. The sterilization method is ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com