Patents

Literature

93results about How to "Improve factory pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

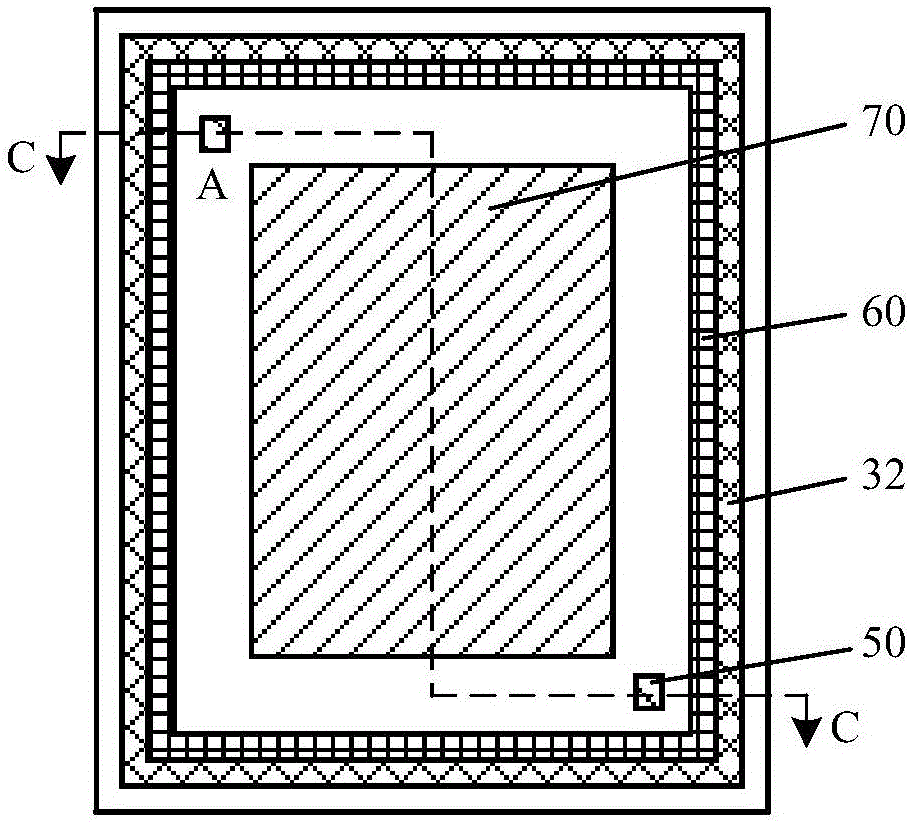

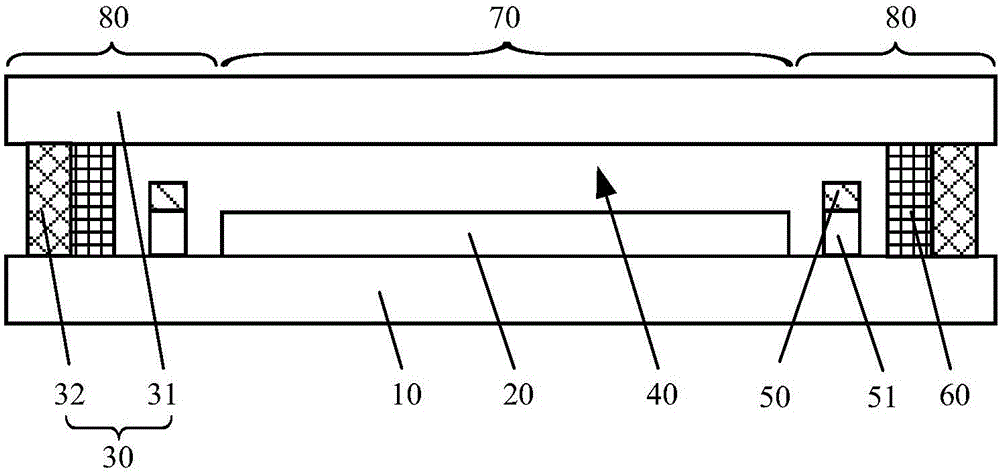

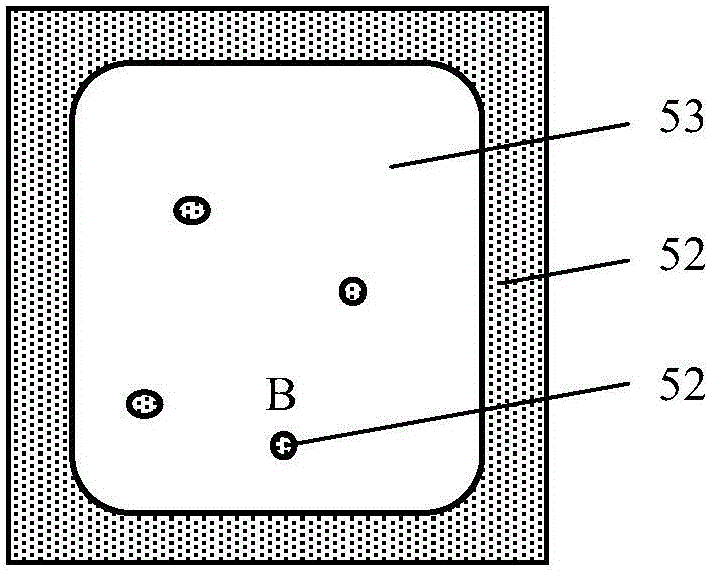

OLED display device and packaging effect maintenance method thereof

ActiveCN106024842AImprove factory pass rateHigh chemical activitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsPass rateDisplay device

The invention discloses an OLED display device and a packaging effect maintenance method thereof, relates to the technical field of display, and aims at enhancing the ex-factory pass rate of the OLED display device. The OLED display device comprises an underlying substrate, an OLED device and a packaging structure. A packaging cavity is formed between the packaging structure and the underlying substrate. The OLED device is arranged in the packaging cavity. The OLED display device also comprises a detection part which is arranged in the packaging cavity. The chemical activity of the detection part for water or / and oxygen is the same with that of the OLED device for water or / and oxygen, or the chemical activity of the detection part for water or / and oxygen is the higher than that of the OLED device for water or / and oxygen. The OLED display device is used for displaying frames.

Owner:BOE TECH GRP CO LTD +1

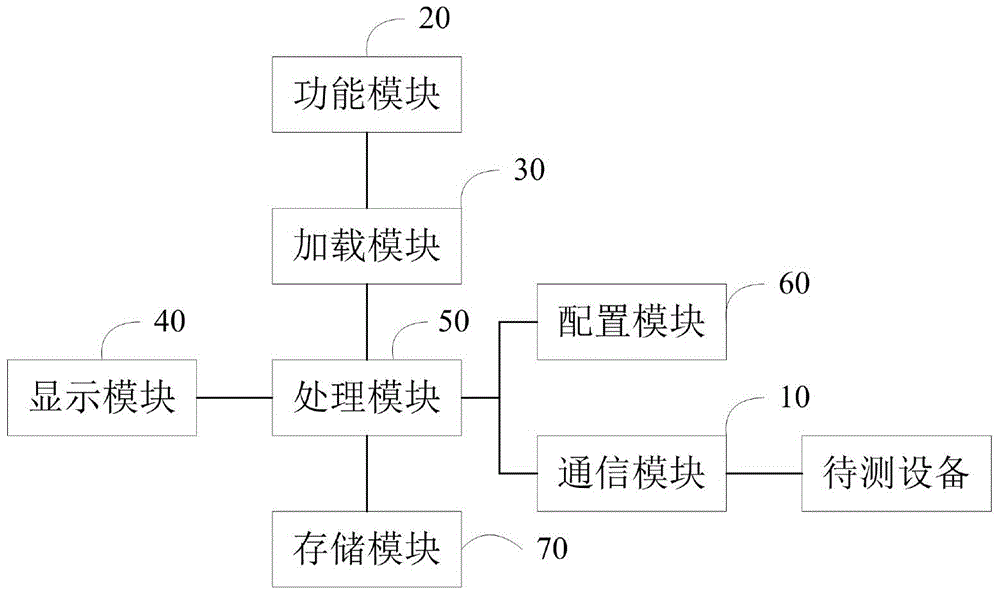

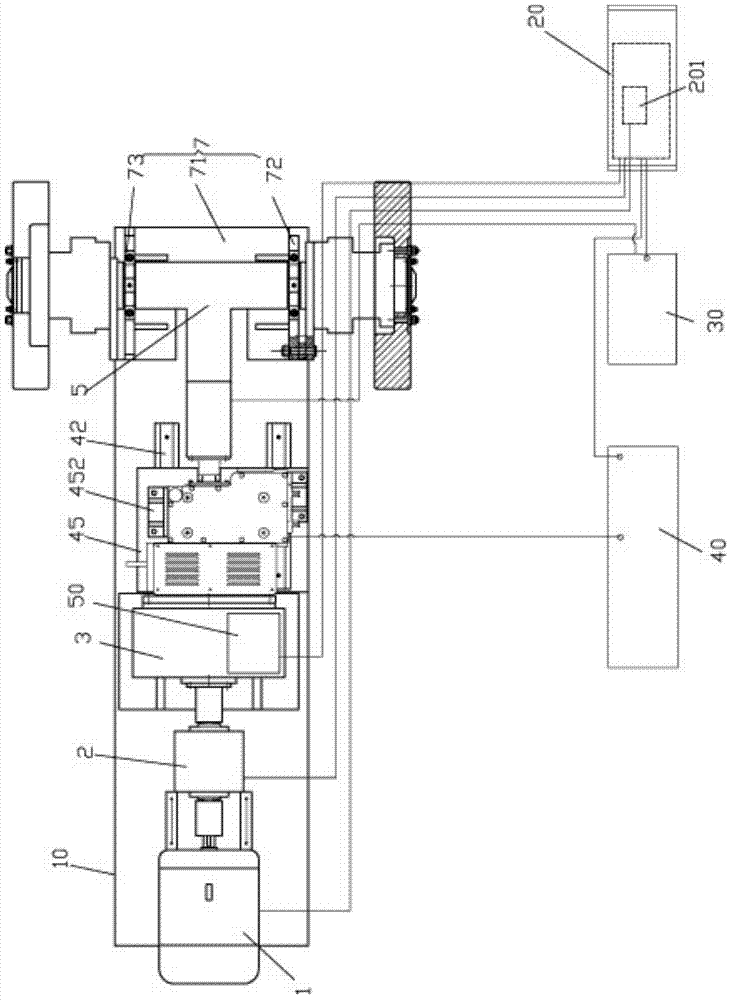

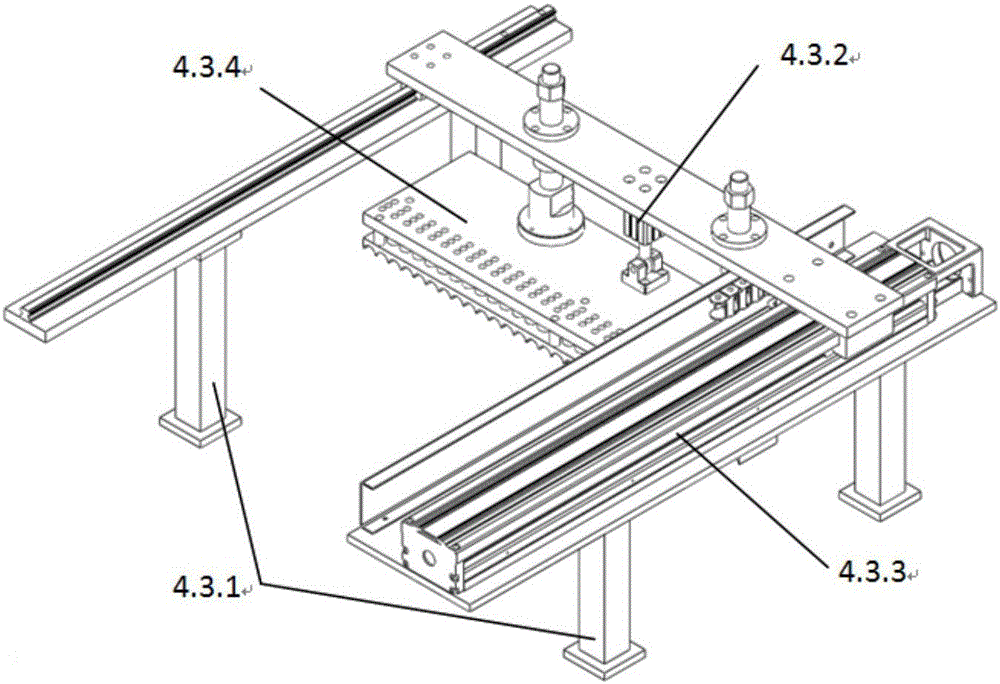

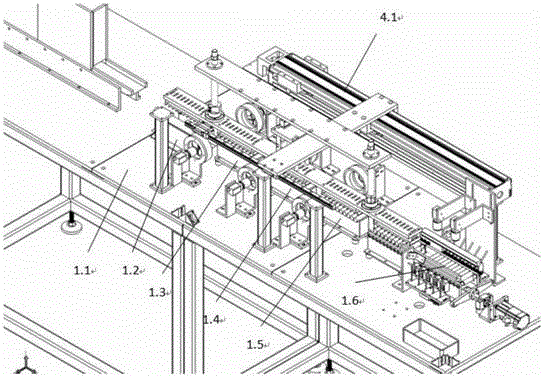

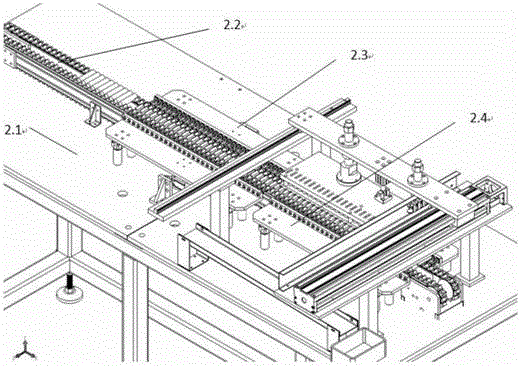

Automatic test system and method

InactiveCN105319455AImprove factory pass rateAdd test functionElectrical testingTest efficiencyModular design

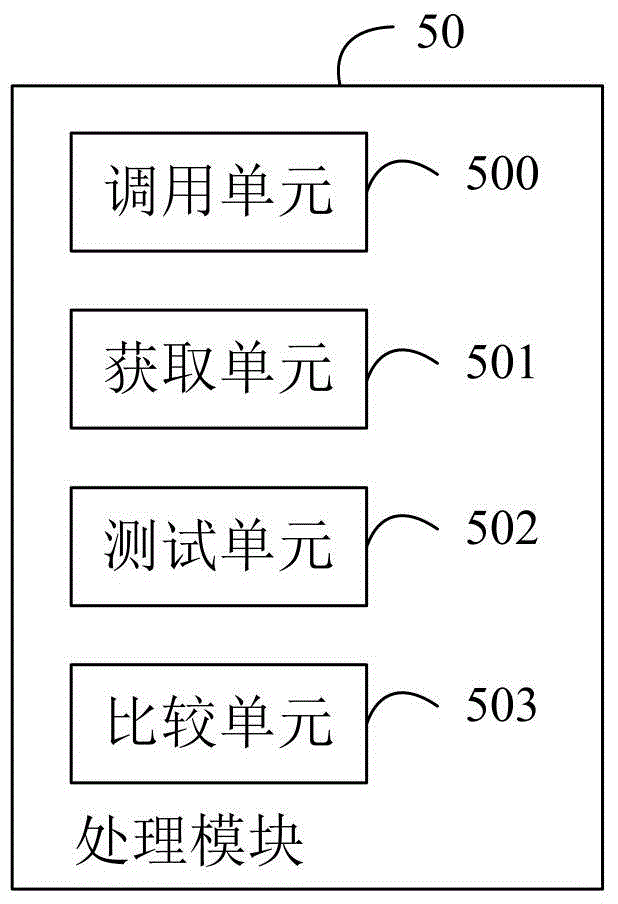

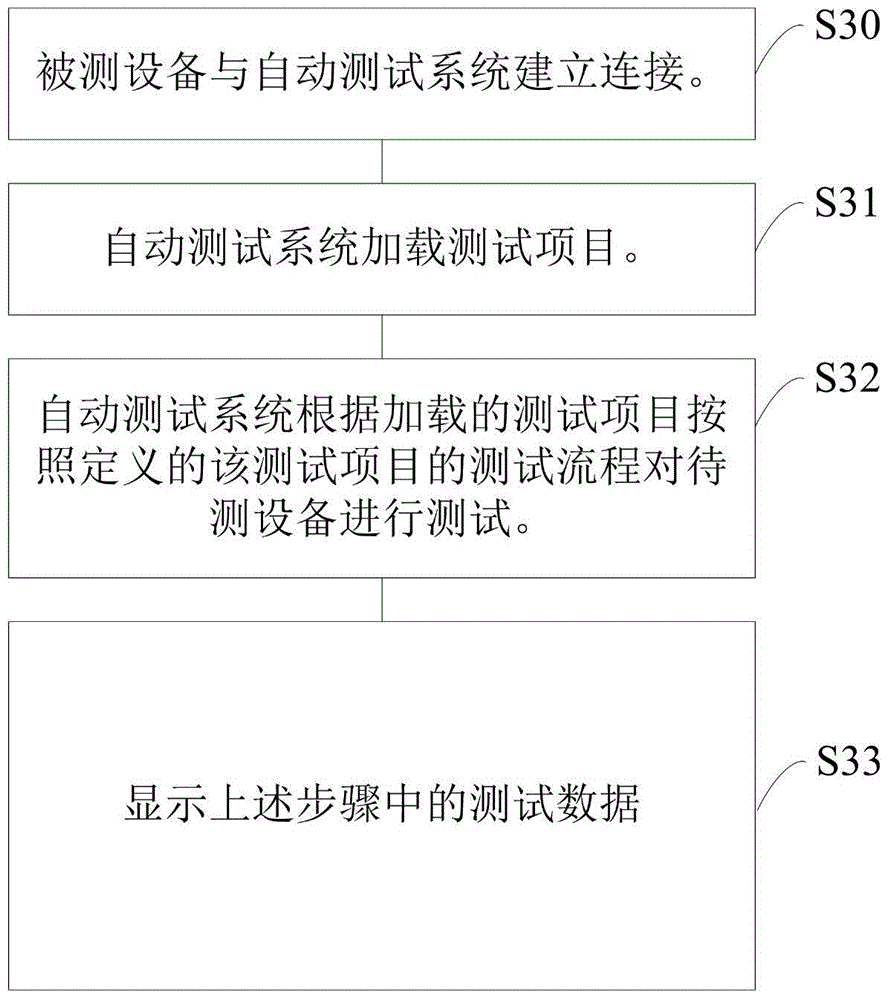

The invention provides an automatic test system. The automatic test system comprises a communication module which is connected with a device to be tested so as to perform data communication with the device to be tested, a function module used for defining test items of the device to be tested and test processes corresponding to the test items, a loading module used for loading the test items to be tested of the device to be tested as current test items, a display module used for displaying test data and test results, and a processing module used for calling the information of the test items loaded by the loading module to execute test processes corresponding to the test items; and the communication module is in data communication with the device to be tested, so that a test be completed, and then, the test data are transmitted to the display module to be displayed. The invention also provides an automatic test method. According to the automatic test system and method of the invention, modular design is adopted, and therefore, test functions can be increased in follow-up stages, and therefore, scalability is high, test efficiency can be improved, and the quality of outgoing products can be improved.

Owner:SKY LIGHT ELECTRONICS SHENZHEN

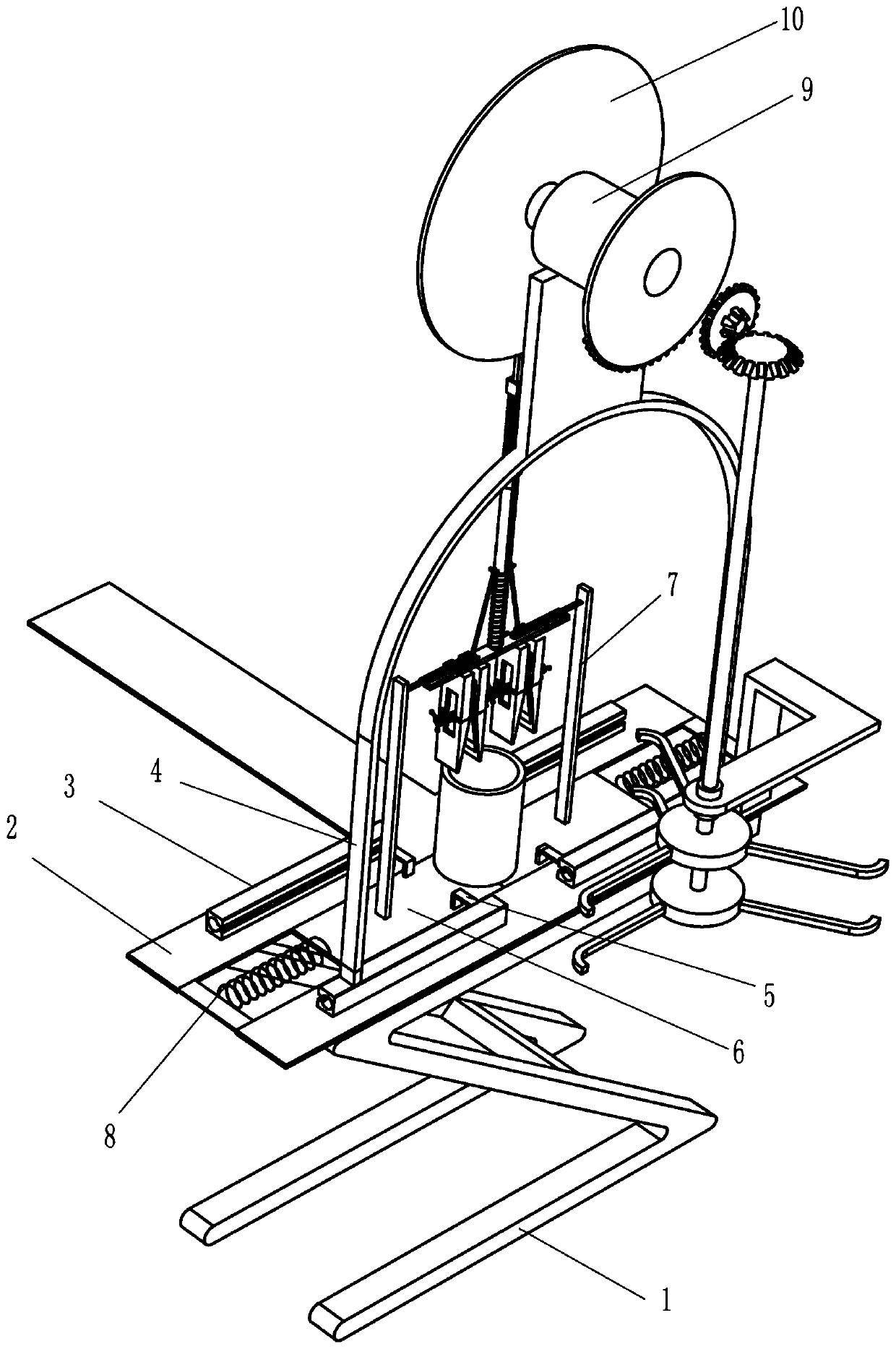

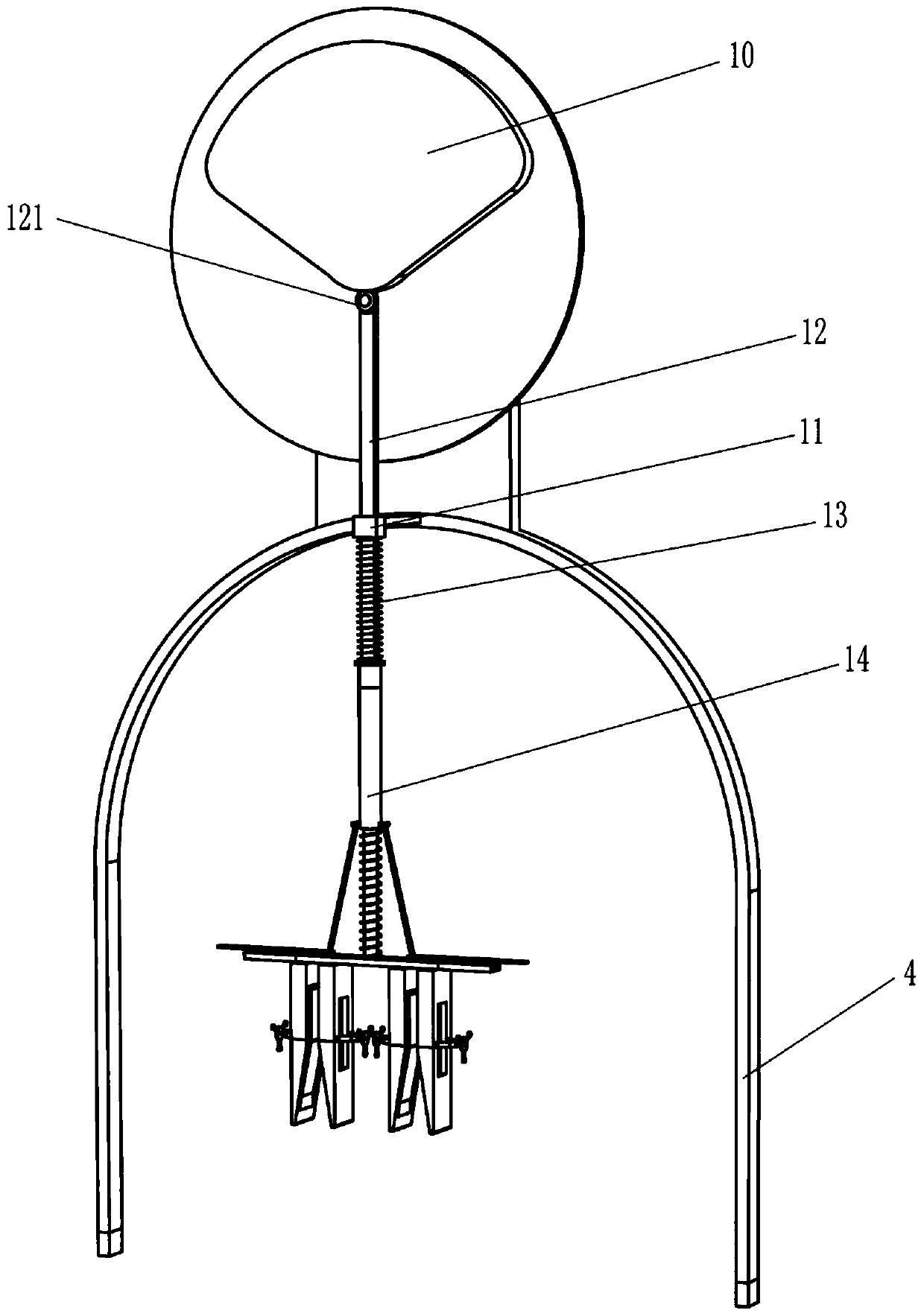

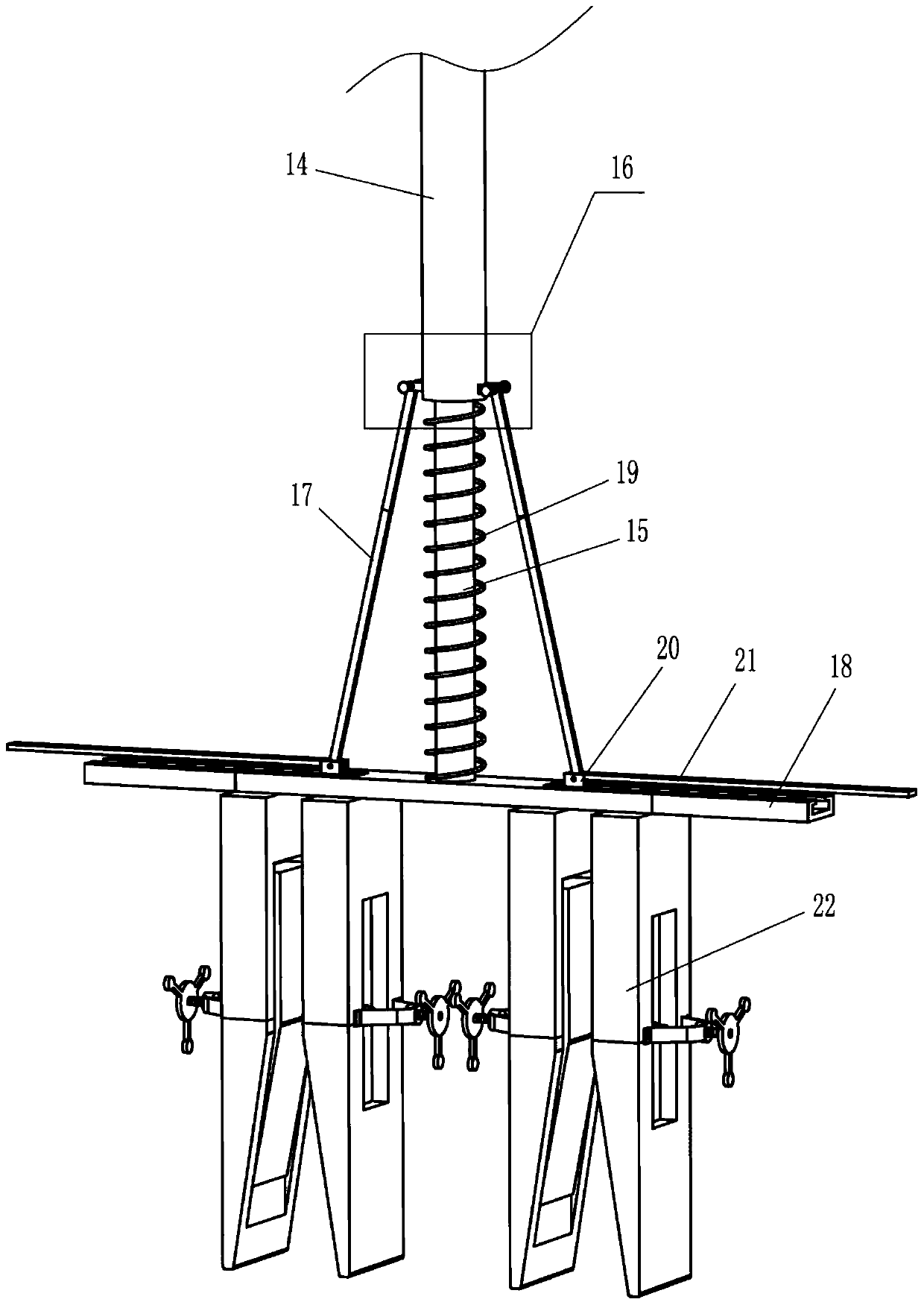

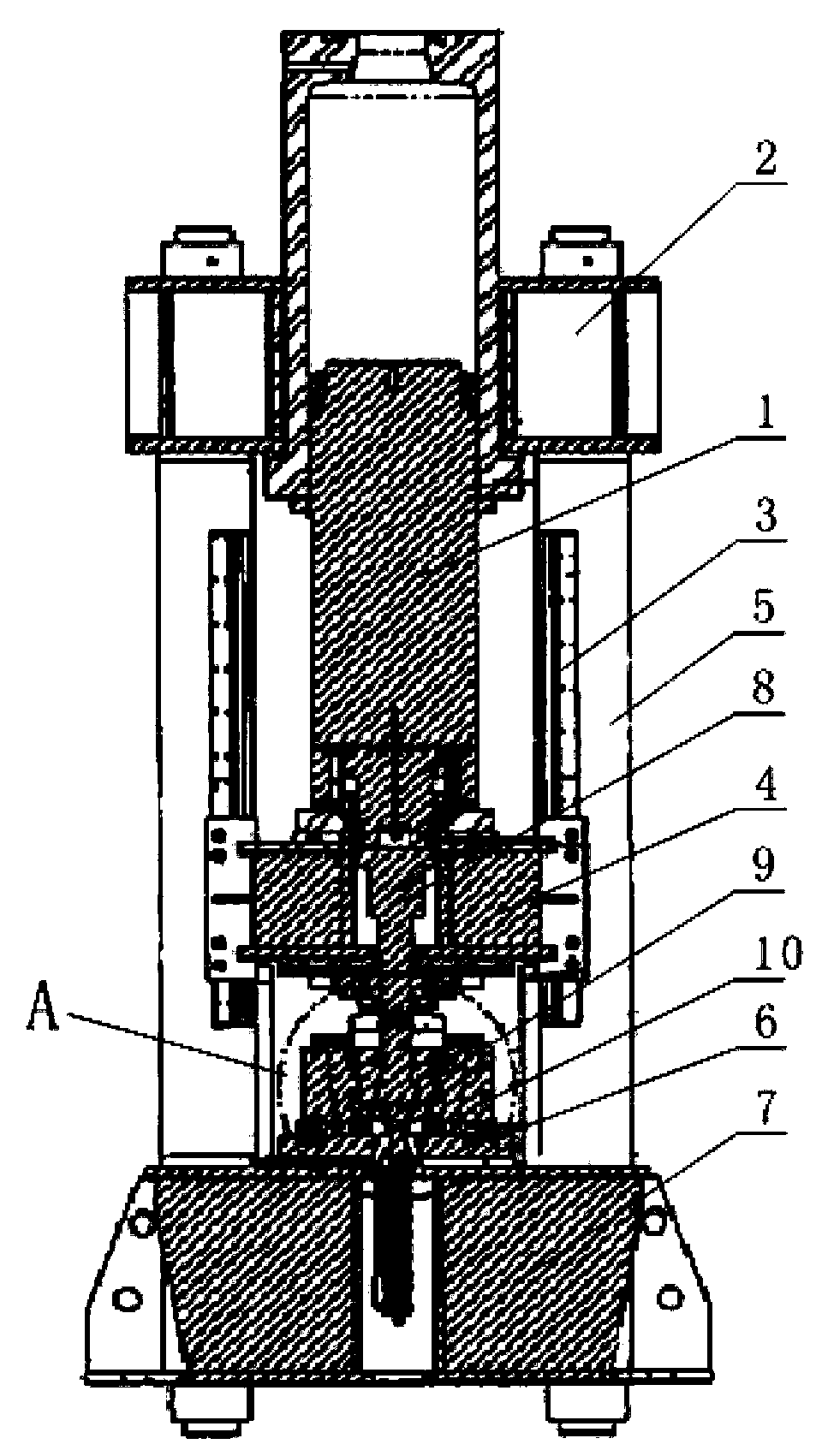

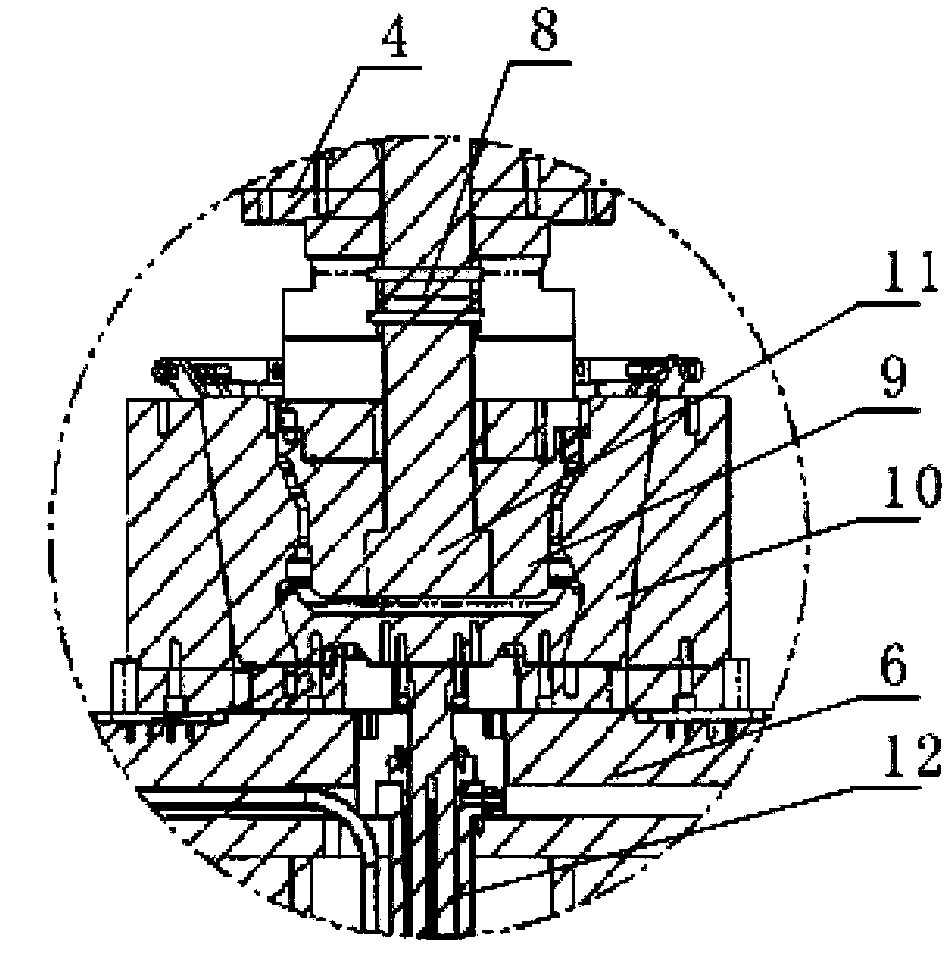

Gearbox test bed

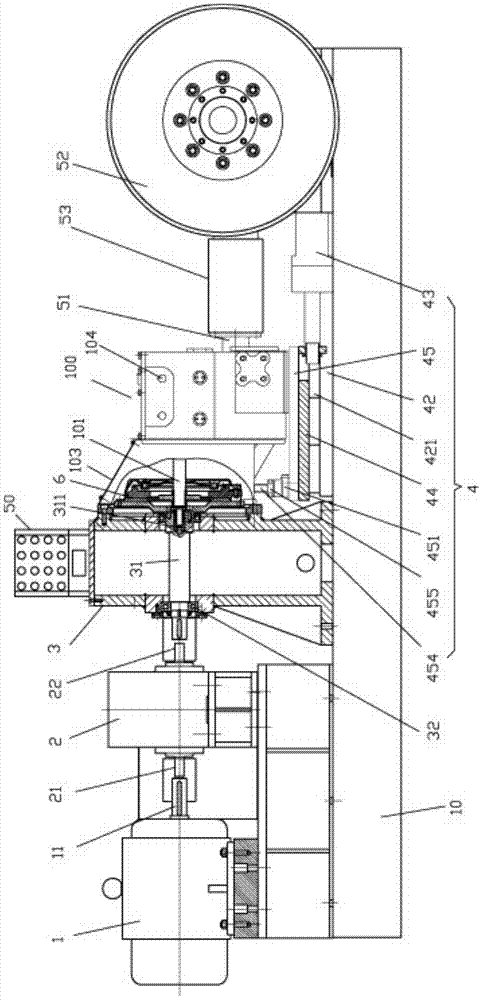

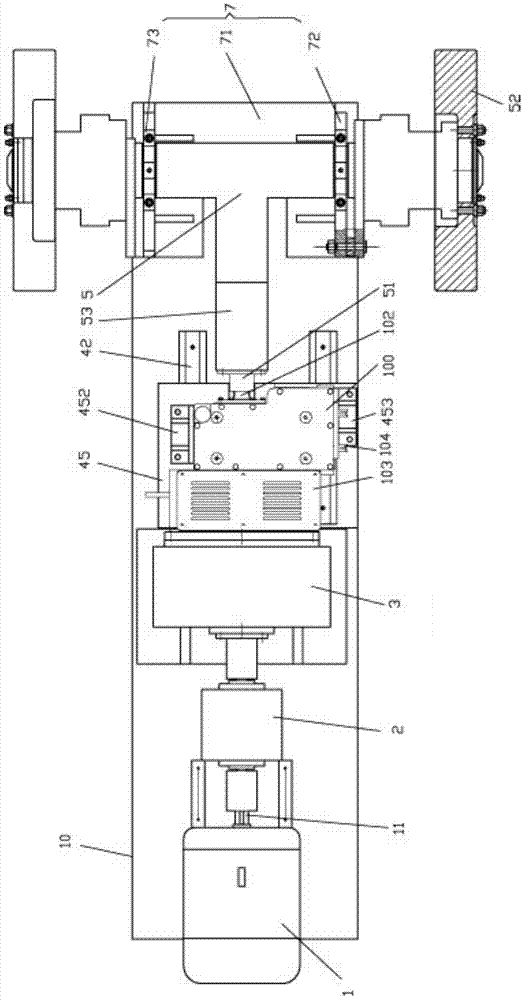

ActiveCN103543009ARealize live simulation operationCheck product qualityMachine gearing/transmission testingIn vehicleCoupling

The invention discloses a gearbox test bed comprising a bed platform, a power control box, a hydraulic station and a mechanical oil tank. A motor, a torque sensor, a mounting block, a floating holder and a drive axle are sequentially disposed on the bed platform from left to right. A motor output shaft of the motor is connected with a left input shaft of the torque sensor through a coupling. A right output shaft of the torque sensor is connected with the left end of a spindle hinged to the mounting block, through another coupling. A clutch assembly is fixed at the right end of the spindle. The motor, the torque senor, the mounting block, the floating holder and the drive axle are disposed on the bed platform, the motor is subjected to variable frequency control through a controller and the power control box so as to achieve actual simulation run, whether noise produced by a gearbox normally operating meet the requirements or not can be detected, the noise produced by the gearbox in vehicle acceleration or stopping can also be detected, product quality can be controlled effectively, and ex-factory pass rate is increased.

Owner:ZHEJIANG ZHONGCHAI MACHINERY

Type 18650 lithium ion battery's automatic detection line and the method

ActiveCN105910645ARealize quality managementImprove detection efficiencyMeasurement devicesProgramme control in sequence/logic controllersInternal resistancePhysical chemistry

The invention discloses a type 18650 lithium ion battery's automatic detection line and the method. The detection line comprises a lithium ion battery appearance and size detection module, an electric property detection module and a leakage and code spraying module with the functions of detecting the appearance and size, the electrical property and the sealing performance of the lithium ion battery respectively. The detection line is also provided with an automatic moving device, which ensures that all working procedures function in an organized order. The electrical property detection module is provided with a lithium ion battery internal resistance detection device and a charging-and-discharging device with the functions of detecting the lithium ion battery internal resistance and the charging and discharging properties respectively. The leakage and code spraying module is provided with a leakage detection device and a code spraying device with the functions of detecting the sealing performance of the lithium ion battery and the spraying of a qualified code onto a qualified lithium ion battery respectively. Among the modules of the detection line are recycling boxes for defective lithium ion batteries. At the tail part of the detection line is a box for qualified products. Simple in structure and reliable in performance, the functions of the detection line are well improved and stable enough to greatly save labor force.

Owner:ZHEJIANG UNIV

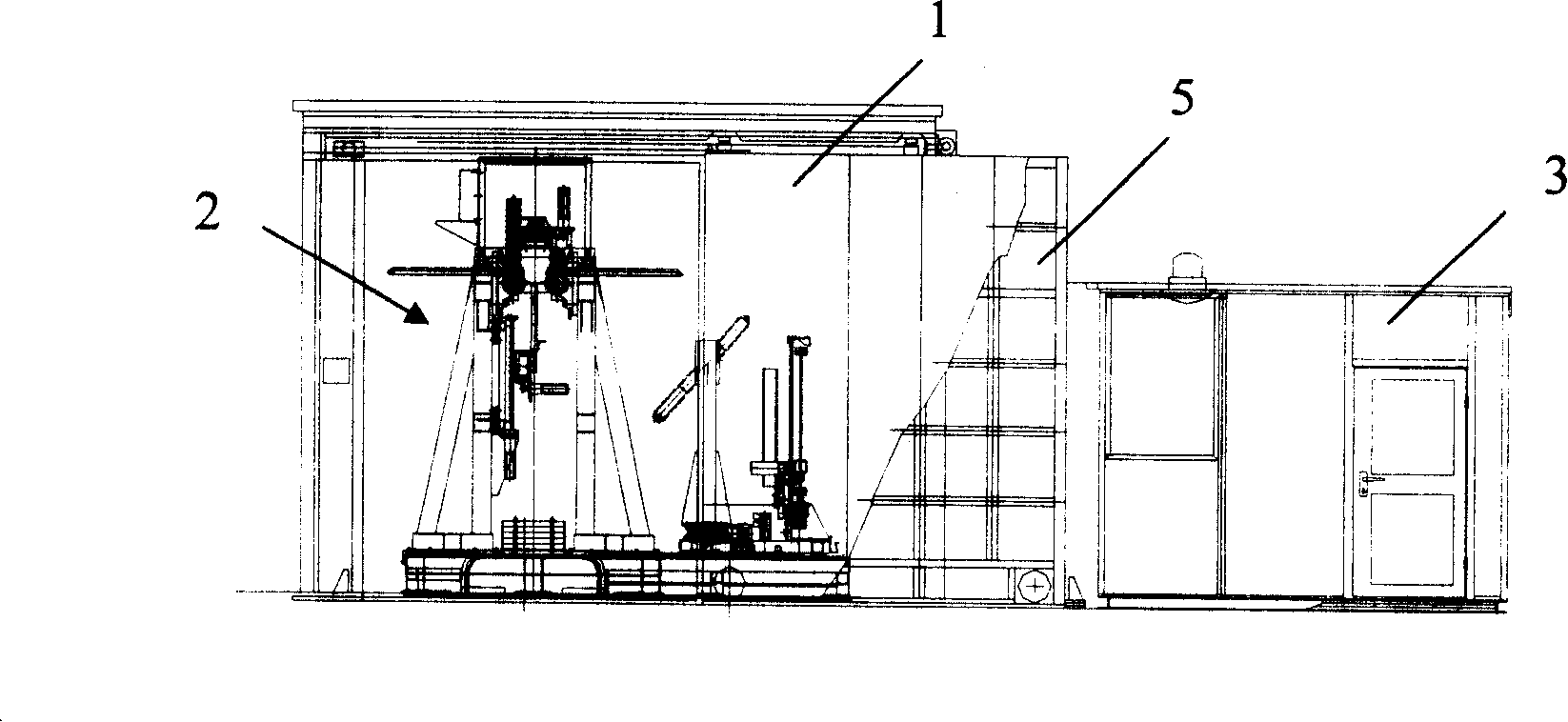

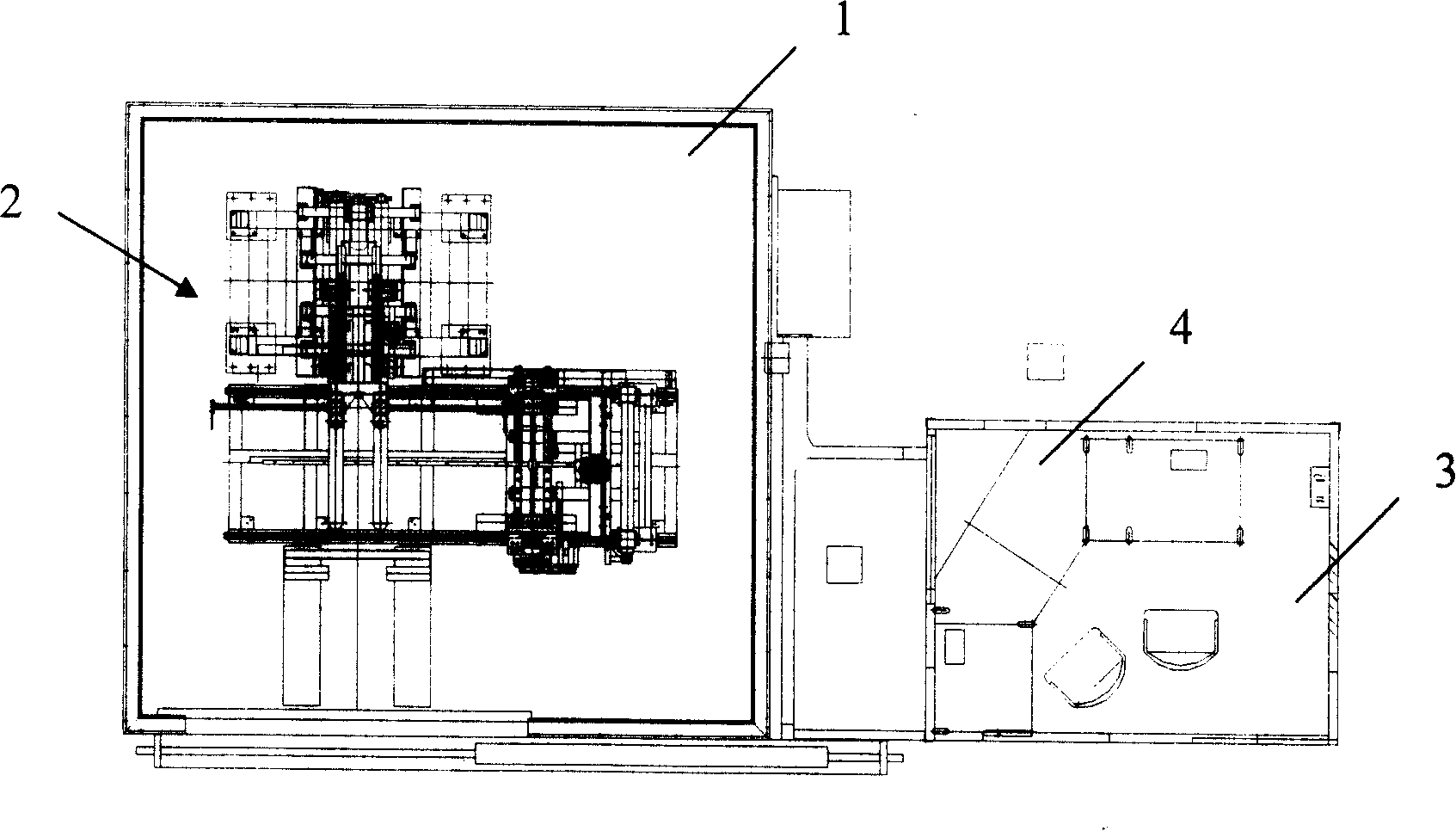

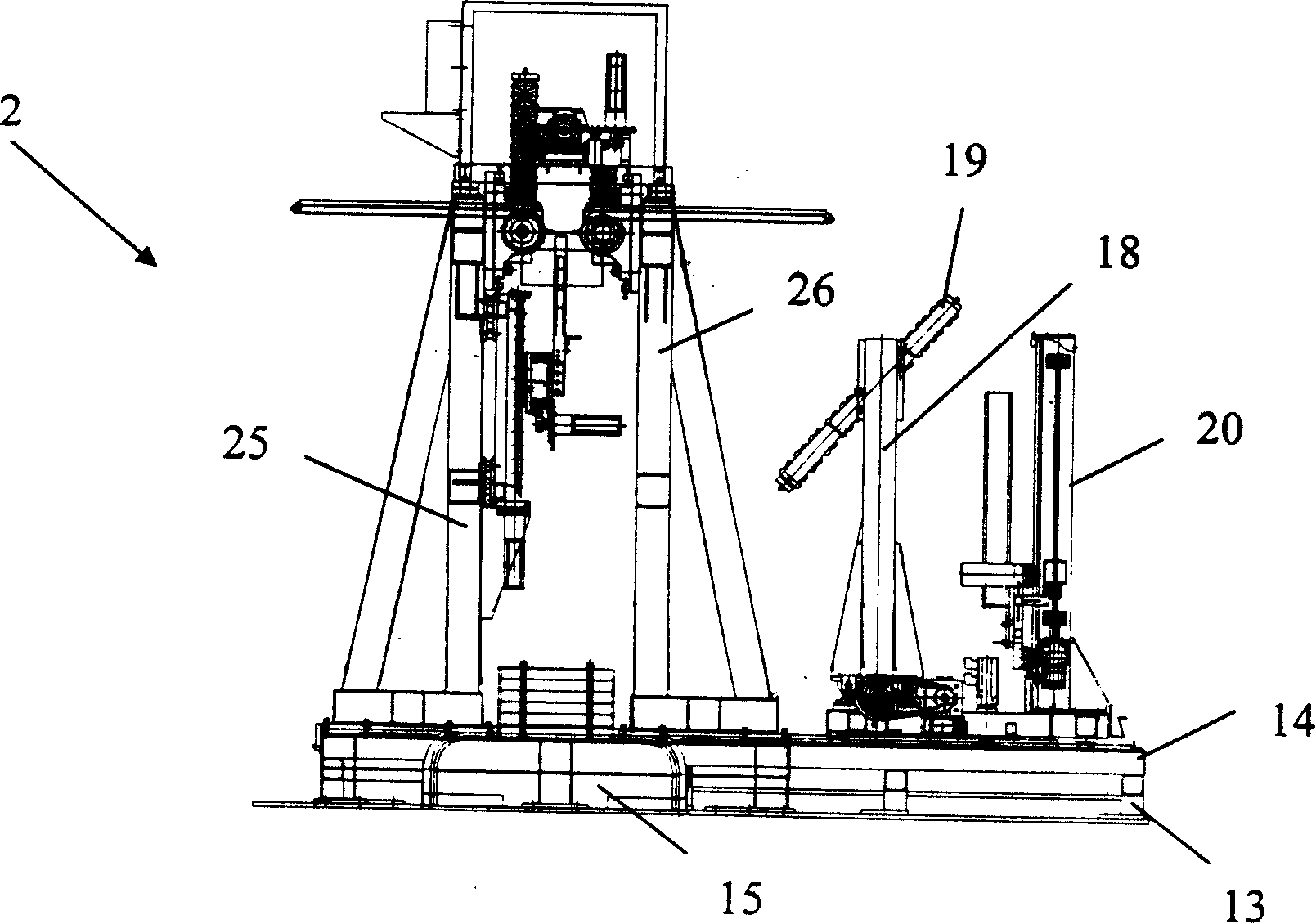

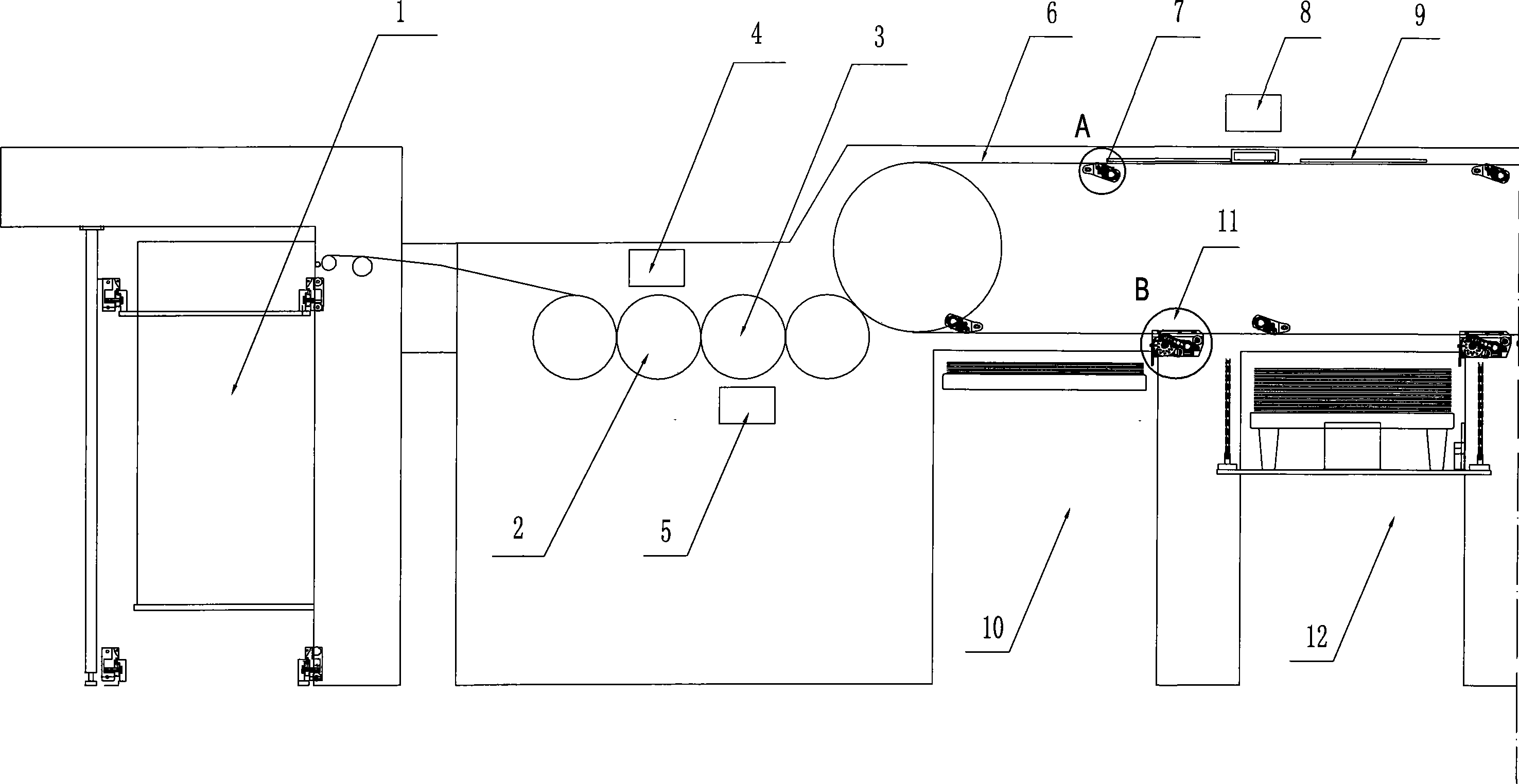

X optical detection machine for project tire

InactiveCN101173907AImprove factory pass rateImprove detection efficiencyMaterial analysis by transmitting radiationPass rateElectrical control

The invention discloses an engineering tire X-ray detection machine. It includes a lead room, a detection device, a control room and an electrical control device; one side of the lead room is equipped with an electric lead room door; the detection device is set inside the lead room, including a trolley group, a centering device, and a U-shaped frame group. , main frame group, opposite side group, drive group and ball head group; the control room is set on the outer side of the lead room; and the electrical control device is set inside the control room. The X-ray detection machine for engineering tires provided by the invention can automatically complete the positioning of engineering tires, X-ray scanning, receiving, converting and image display of detection signals, and thus has a high degree of automation. Since each engineering tire can be automatically inspected and analyzed for its internal quality, it plays a scientific role in improving the pass rate of engineering tires, and can greatly improve the efficiency of tire inspection and reduce the labor intensity of inspectors.

Owner:张芝泉

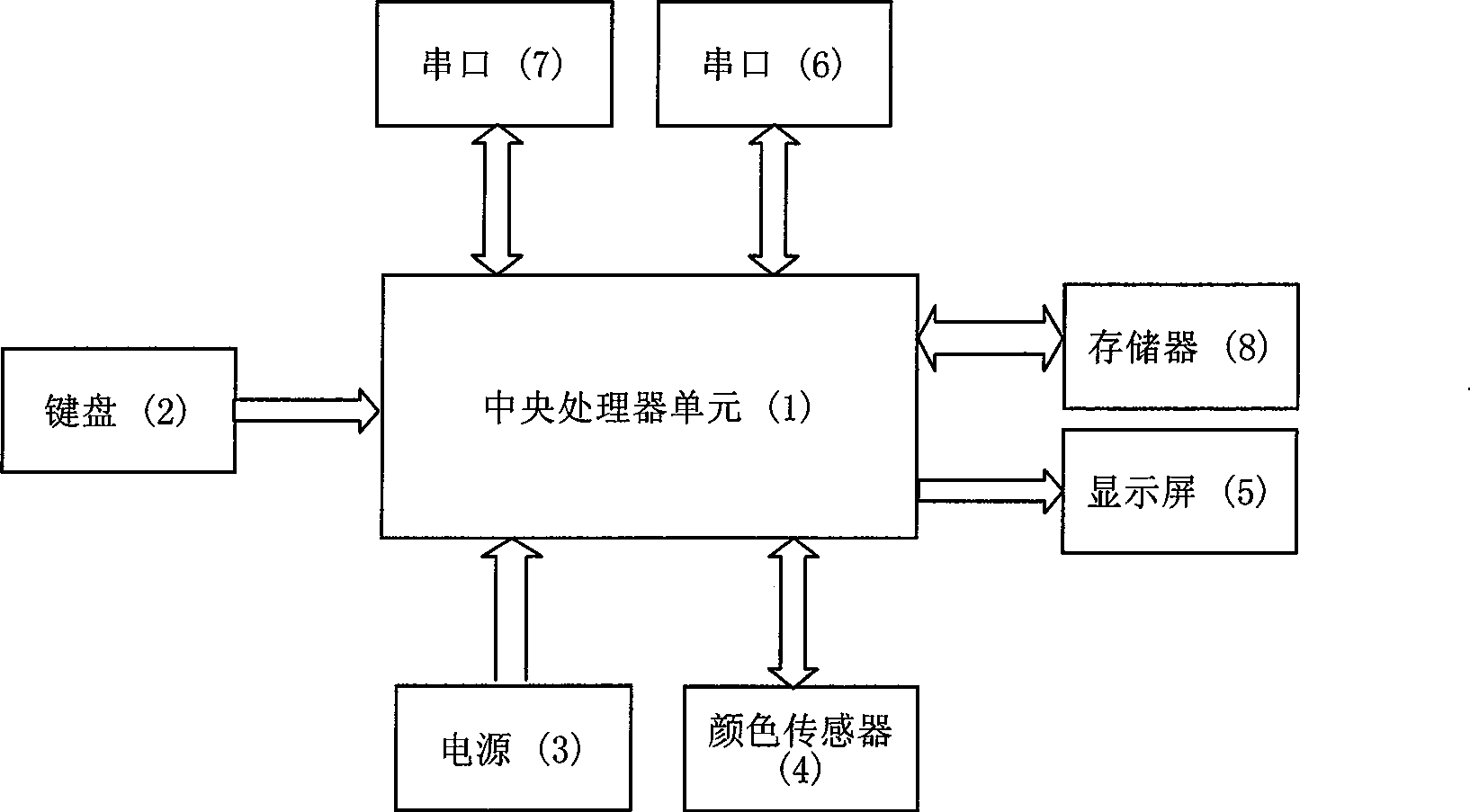

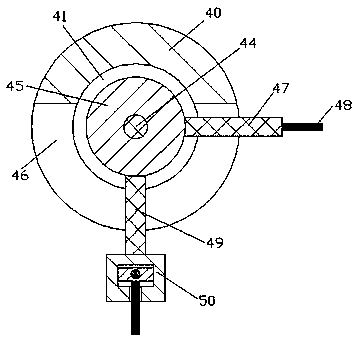

Automatic calibration instrument and calibration method for RGB chatoyancy LED lamp

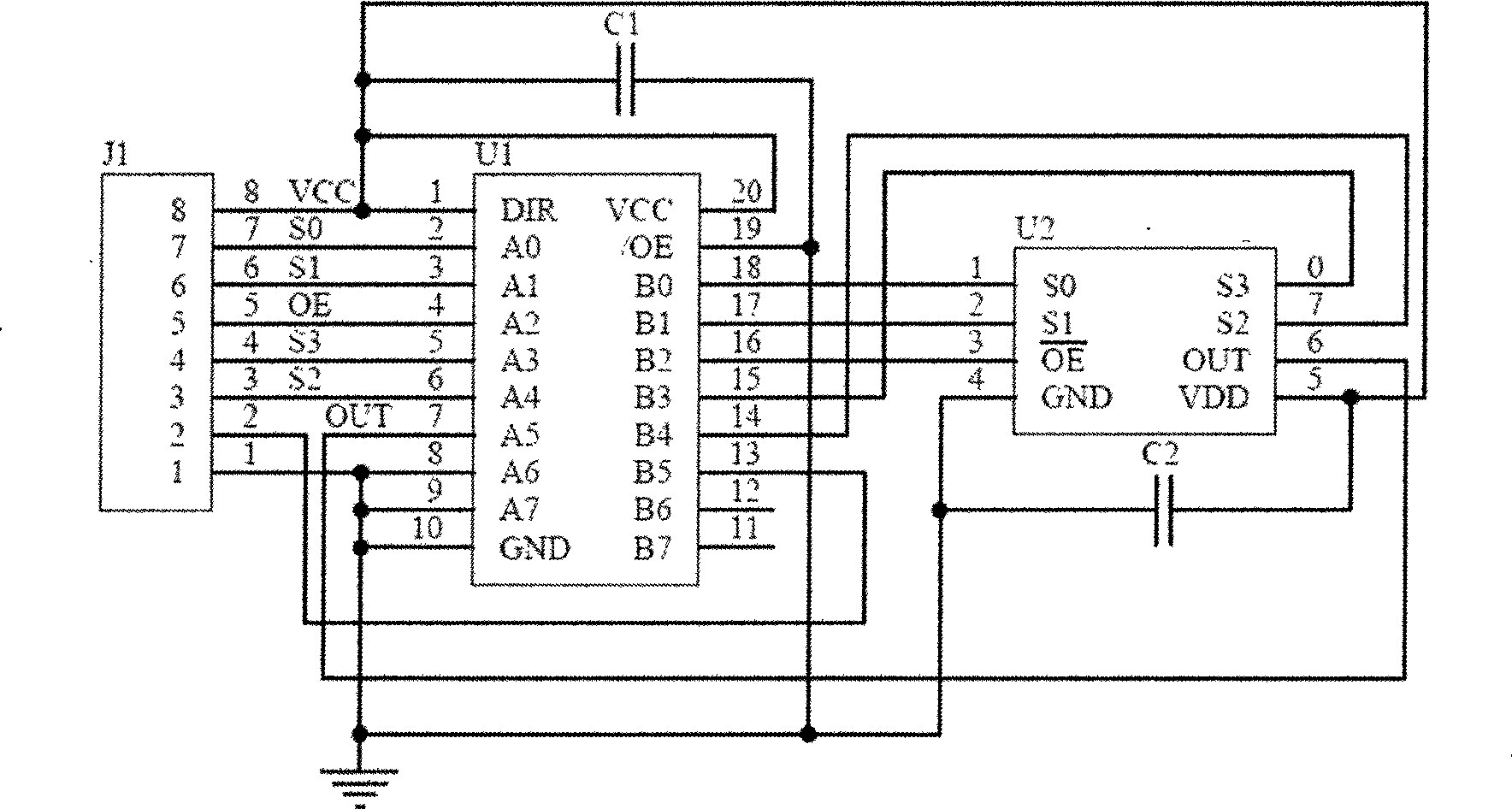

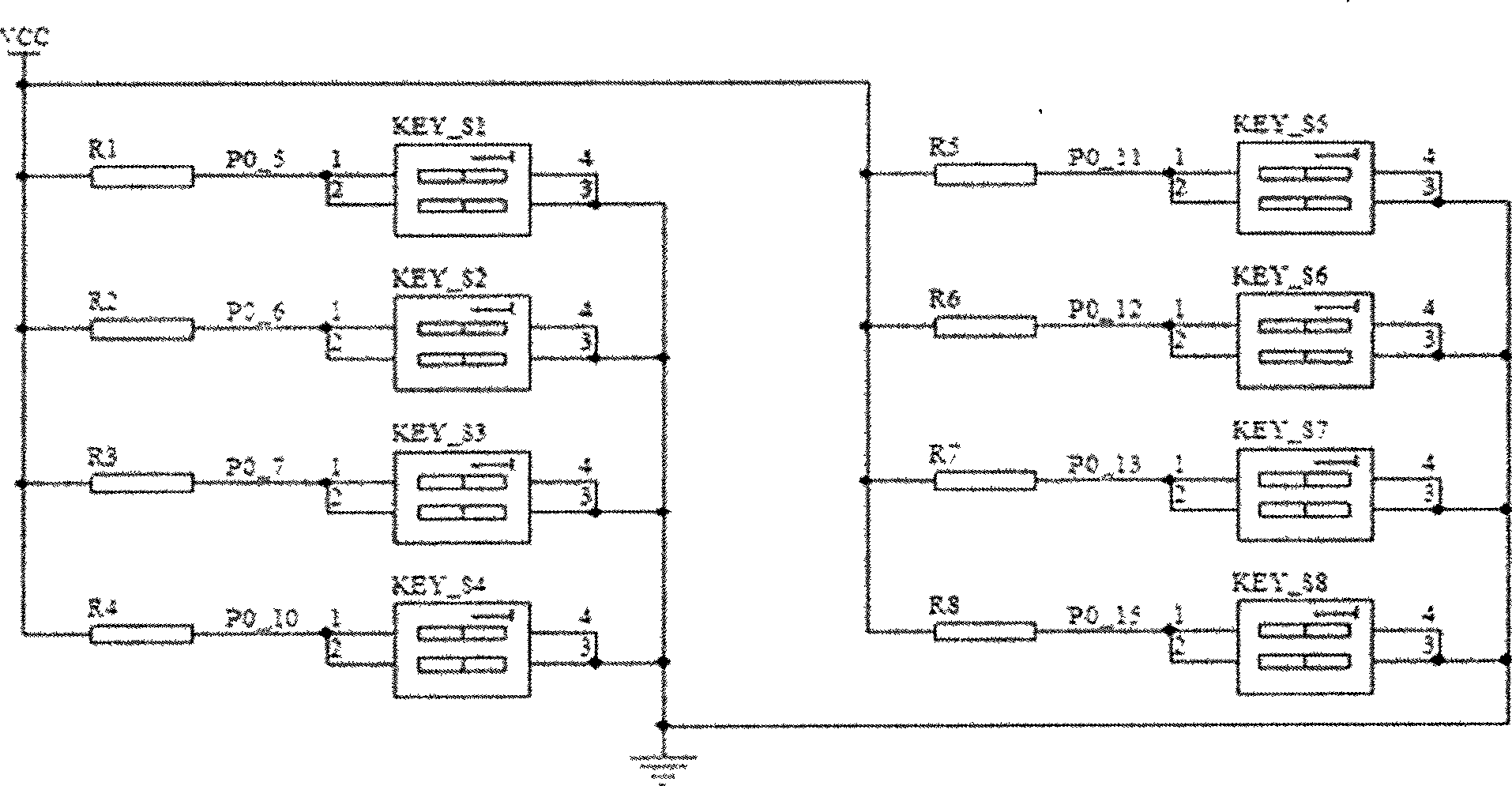

ActiveCN101437340ASimple structureImprove factory pass rateElectric light circuit arrangementElectric programme controlCommunication interfaceEffect light

The invention discloses an automatic calibration instrument for an RGB variable color LED lamp, and a calibration method. The calibration instrument comprises a power source, a color sensor, a keyboard, a storage, a display screen, a central processing unit and a communication interface, wherein the central processing unit is loaded with control software provided with control parameters for adjusting RGB color; the communication interface is connected with an LED lamp controller; and the central processing unit is respectively connected with the power source, the color sensor, the keyboard, the storage, the display screen and the communication interface. The calibration method comprises the following steps: an RGB color setting value is obtained from the storage; the color sensor is used to obtain an RGB color actual measured value; the control software compares the RGB color setting value with the RGB color actual measured value, and obtains corresponding control parameters for adjusting RGB color according to difference between the setting value and the measured value; and the control parameters are transmitted to the LED lamp controller through a serial port and the LED lamp controller is responsible for executing calibration; therefore, different RGB variable color LED lamps have the same color in the same color lighting mode.

Owner:ZHEJIANG SHENGHUI LIGHTING

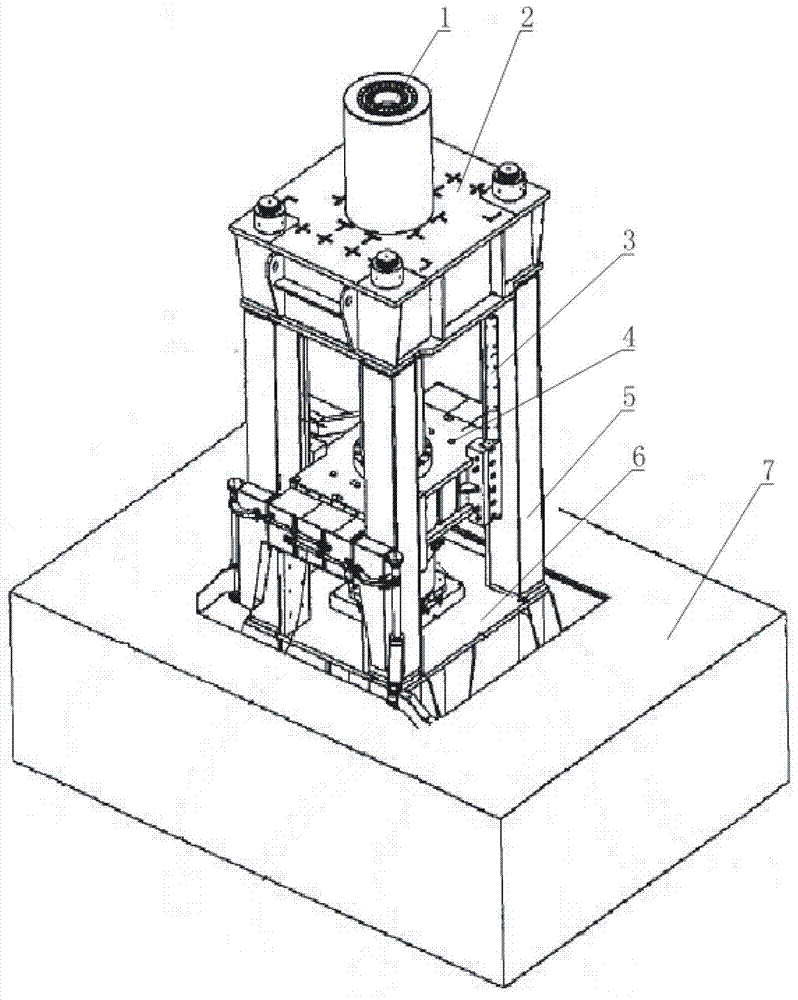

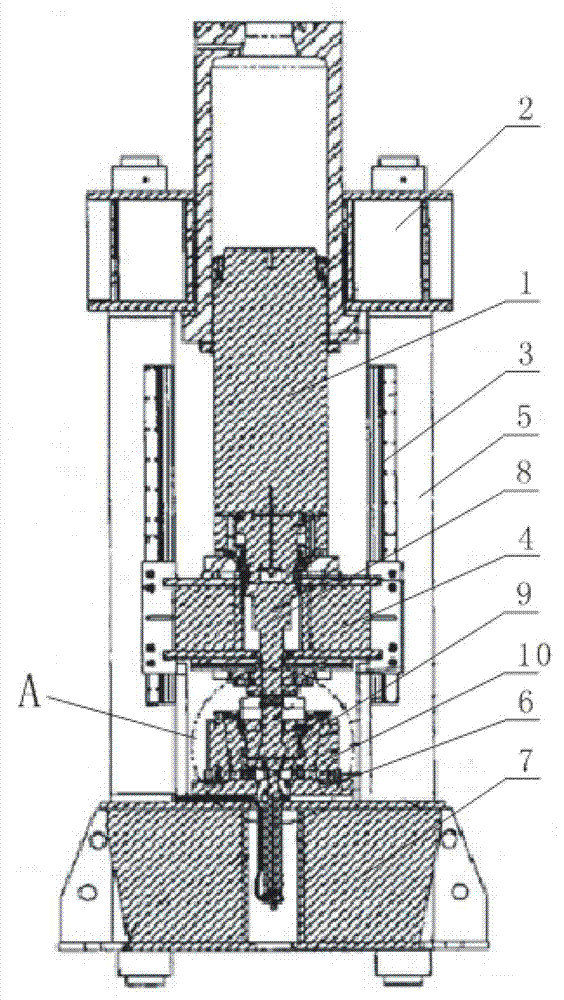

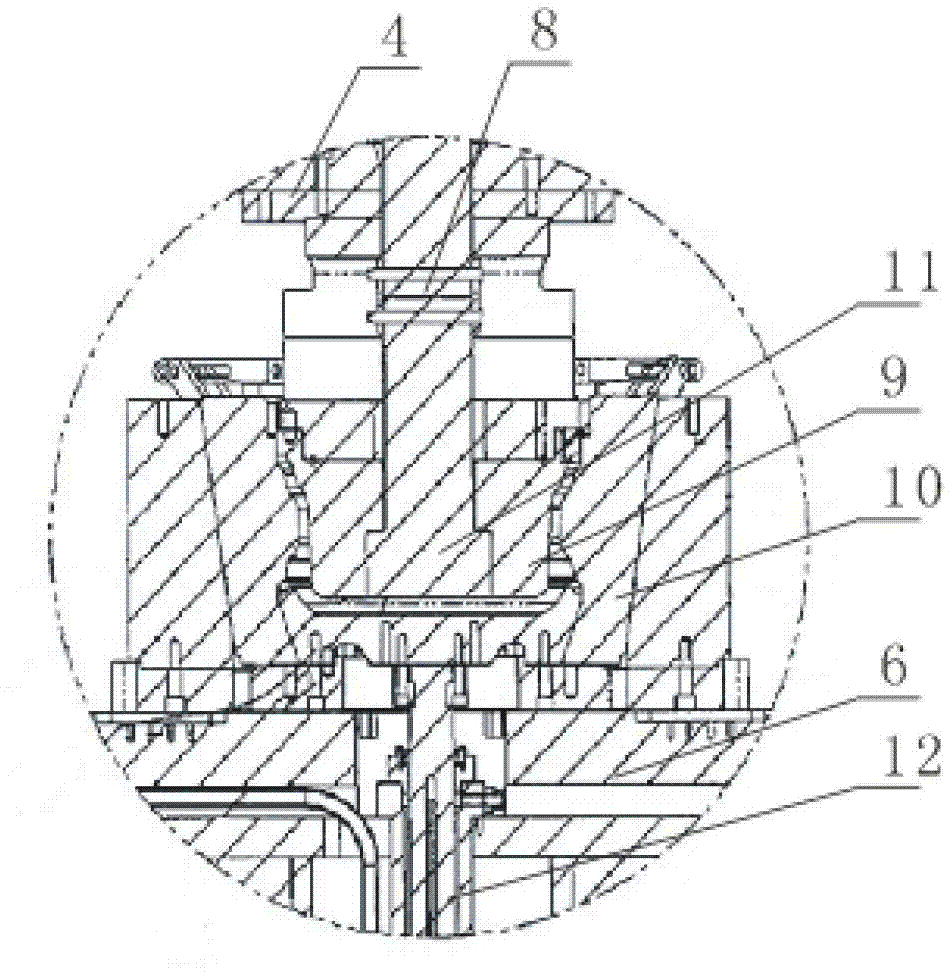

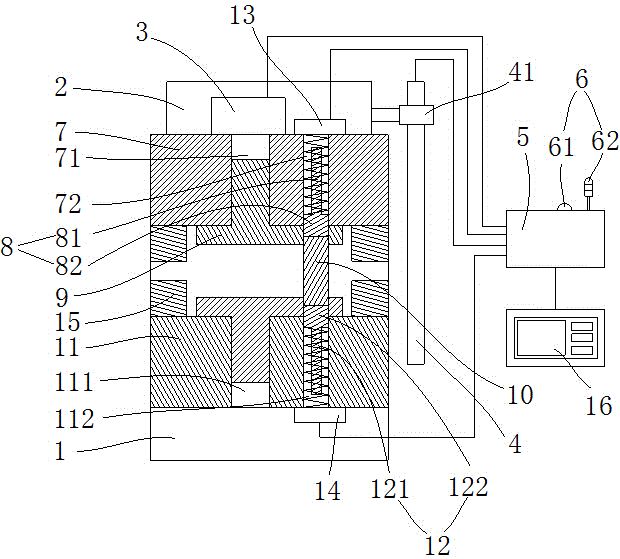

Forging method and forging device of twice forcing molten soup forging wheel

ActiveCN103084559AAvoid damageMeet mechanical performance requirementsRefined grainsMechanical property

The invention relates to a forging method and a forging device of a twice forcing molten forging wheel. The forging method of the twice forcing molten forging wheel is conducted circularly by the following steps: (1) materials smelting; (2) heat preservation deposit; (3) molten soup degassing; (4) the molten soup being injected into a lower die; (5) main piston forcing and pressure maintaining; (6) auxiliary piston forcing and pressure maintaining; (7) die sinking; (8) product transfer and deposit; (9) die cooling. Product quality is improved and molten soup dosage is reduced, and twice forcing is conducted to further improve inner structure refined grain of metals, and therefore the forging method and the forging device of the twice forcing molten forging wheel has the advantages of improving product mechanical property, tensile property and other overall properties, shortening product production time, increasing output, improving production efficiency and ex-factory percent of pass of products.

Owner:TIANJIN NANUO MACHINERY MFG

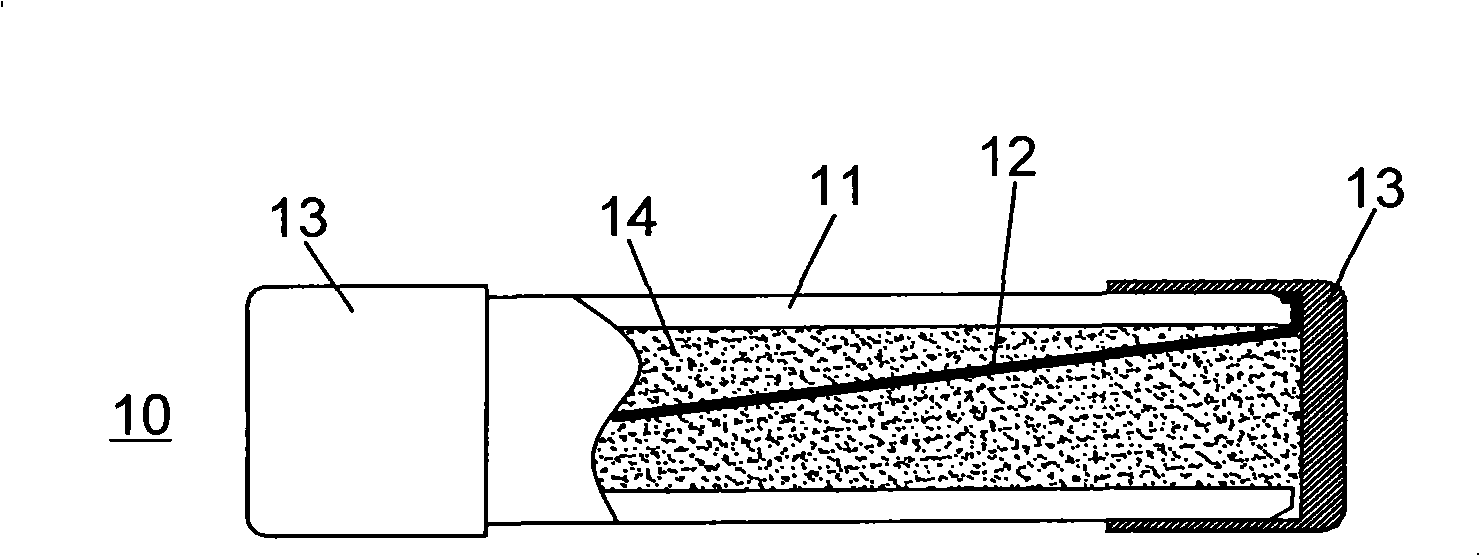

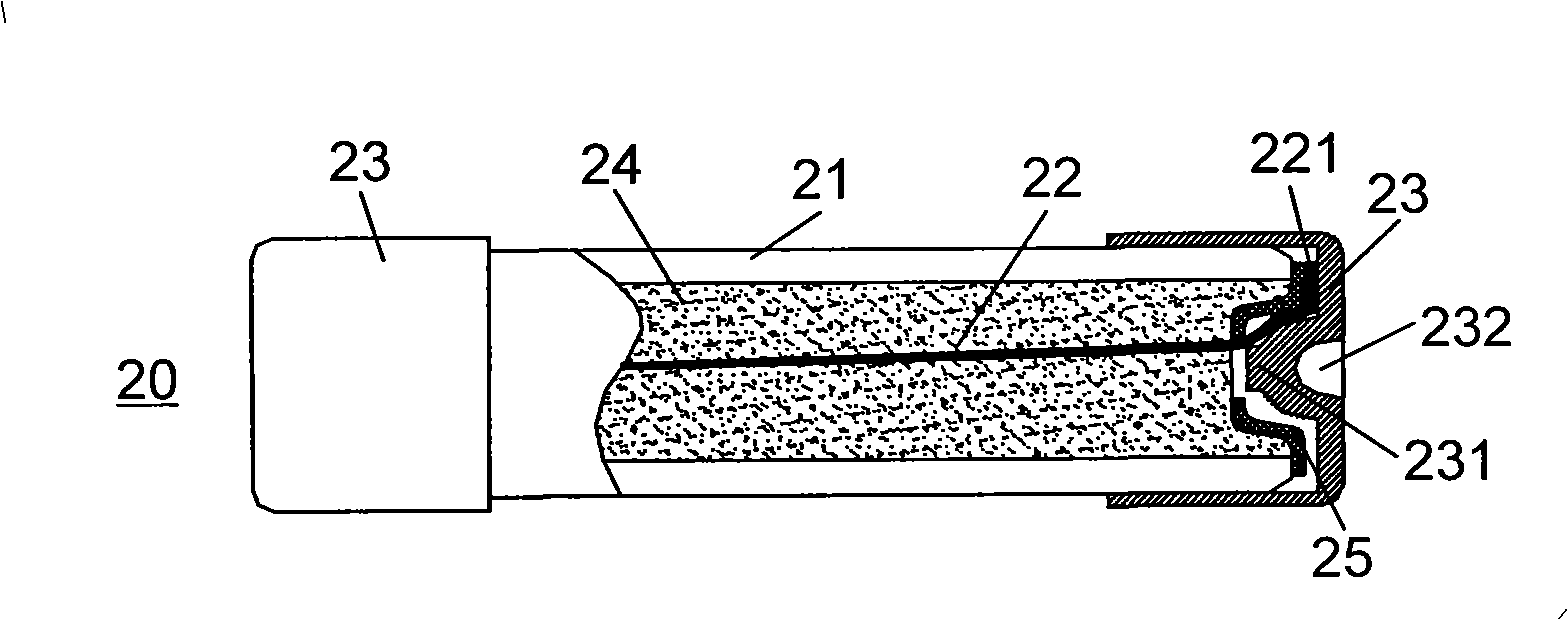

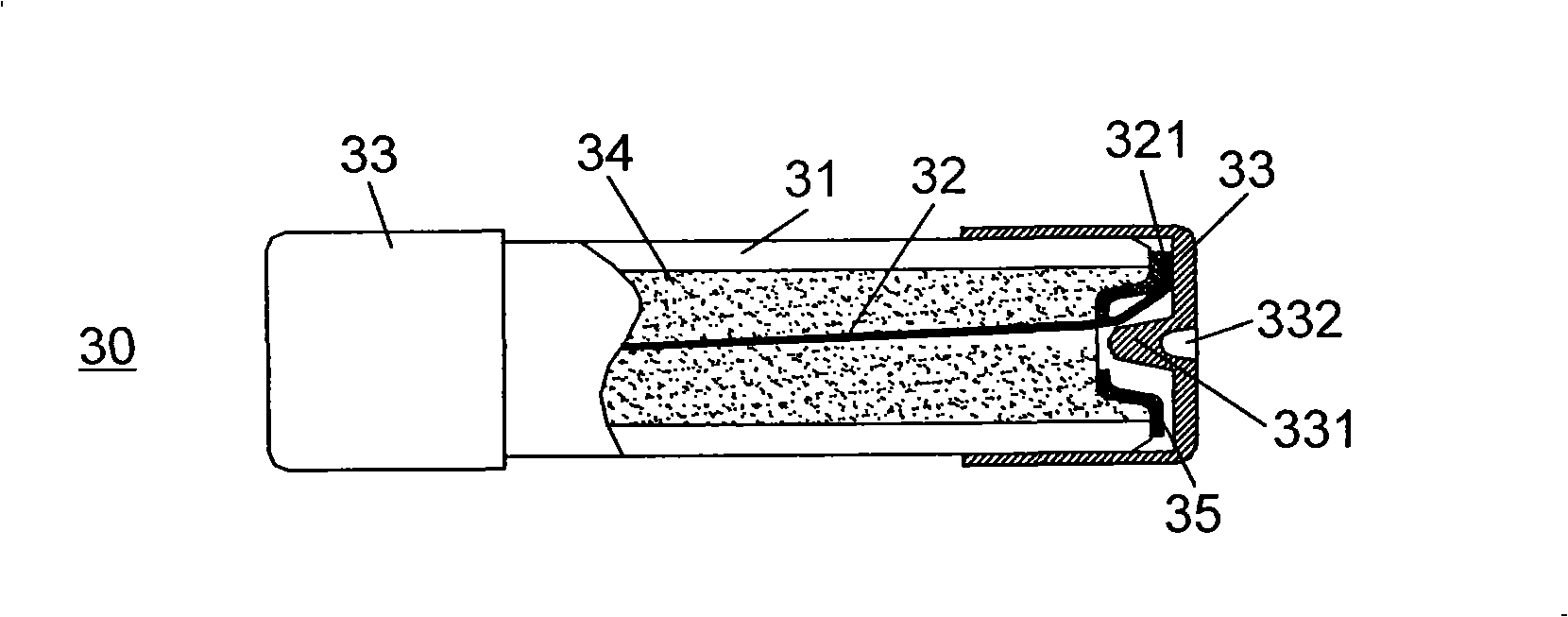

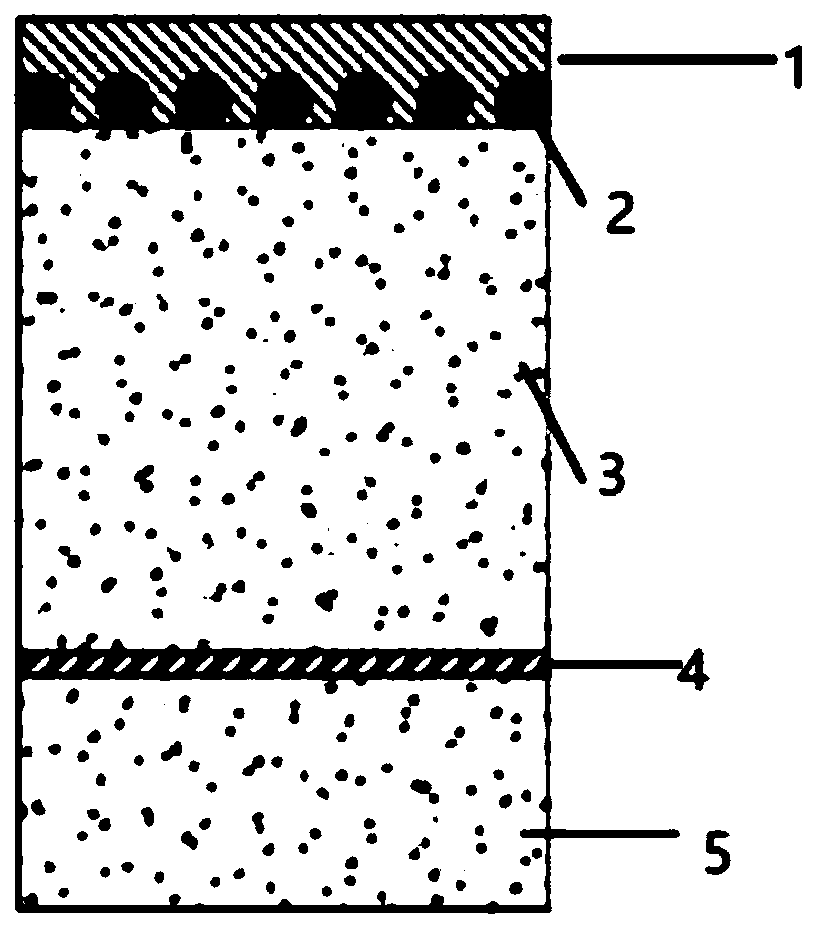

Fuse and assembly method thereof

ActiveCN101308744APrevent overflowAvoid solder overflow and fuse solder joints and prevent overflowEmergency protective devicesSafety wireEconomic benefits

The invention discloses a fuse which comprises a main body, a safety wire and a fixed sealing assembly. The main body is a tubular structure with two open ends and is provided with a quartz sand layer inside. The safety wire stretches into the main body, with both ends extending out of the main body and then bending at the outside. The fixed sealing assembly is composed of a fixed gasket and a sealing cap; the fixed gasket is arranged at two ends of the main body and rests against the two ends of the main body, and the sealing cap is fixedly hitched at two ends of the main body, respectively resting against the fixed gasket and the safety wire. The invention further discloses a fuse installation method. The fuse and the installation method are simple and convenient; the fuse is reliable in performance and resurfacing welding is not required during the installation, thus avoiding overflow of the solder and fault soldered joint and preventing the safety fuse from being broken by compression; therefore good contact between the safety wire and the sealing cap and the integrity of the product can be ensured, thus improving qualification rate and economic benefits.

Owner:COOPER ELECTRONICS TECH SHANGHAI

Vacuum leak-detection sterile dual-valve soft bag transfusion combined bag

InactiveCN103961260AThoroughly sterilizedEfficient sterilizationPharmaceutical containersMedical packagingLeak detectionBiomedical engineering

The invention relates to a vacuum leak-detection sterile dual-valve soft bag transfusion combined bag. A manufacturing process of the vacuum leak-detection sterile dual-valve soft bag transfusion combined bag comprises the following steps of sterilizing a material membrane of a liquid medicine bag, feeding the material membrane into a packing workshop, welding the material membrane with a transfusion valve to form an inner packaging bag, filling the inner packaging bag with liquid medicine to form soft bag transfusion, performing sterilization for a second time and performing drying; performing lamp detection for a first time to remove unqualified products with wrong package printing, wrong welding and large impurities in the packaging bag; covering the liquid medicine bag with an outer packaging bag, vacuumizing space between the outer protective bag and the liquid medicine bag or filling space between the outer packaging bag and the liquid medicine bag with protective gas preparations or liquid preparations or solid preparations, performing sterilization for a third time, packing the combined bag in a case, and putting the case in storage for later use; performing lamp detection for a second time to remove leaked products. By means of the vacuum leak-detection sterile dual-valve soft bag transfusion combined bag, bacteria cannot retain in an interlayer, microleaked large volume injection formed in the inner packaging bag can be discharged effectively and conveniently, and the liquid leakage rate when the combined bag leaves the factory is reduced below 0.029%. The period of validity of the vacuum leak-detection sterile dual-valve soft bag transfusion combined bag is prolonged to five years from two years.

Owner:SICHUAN TAIPINGYANG PHARMA

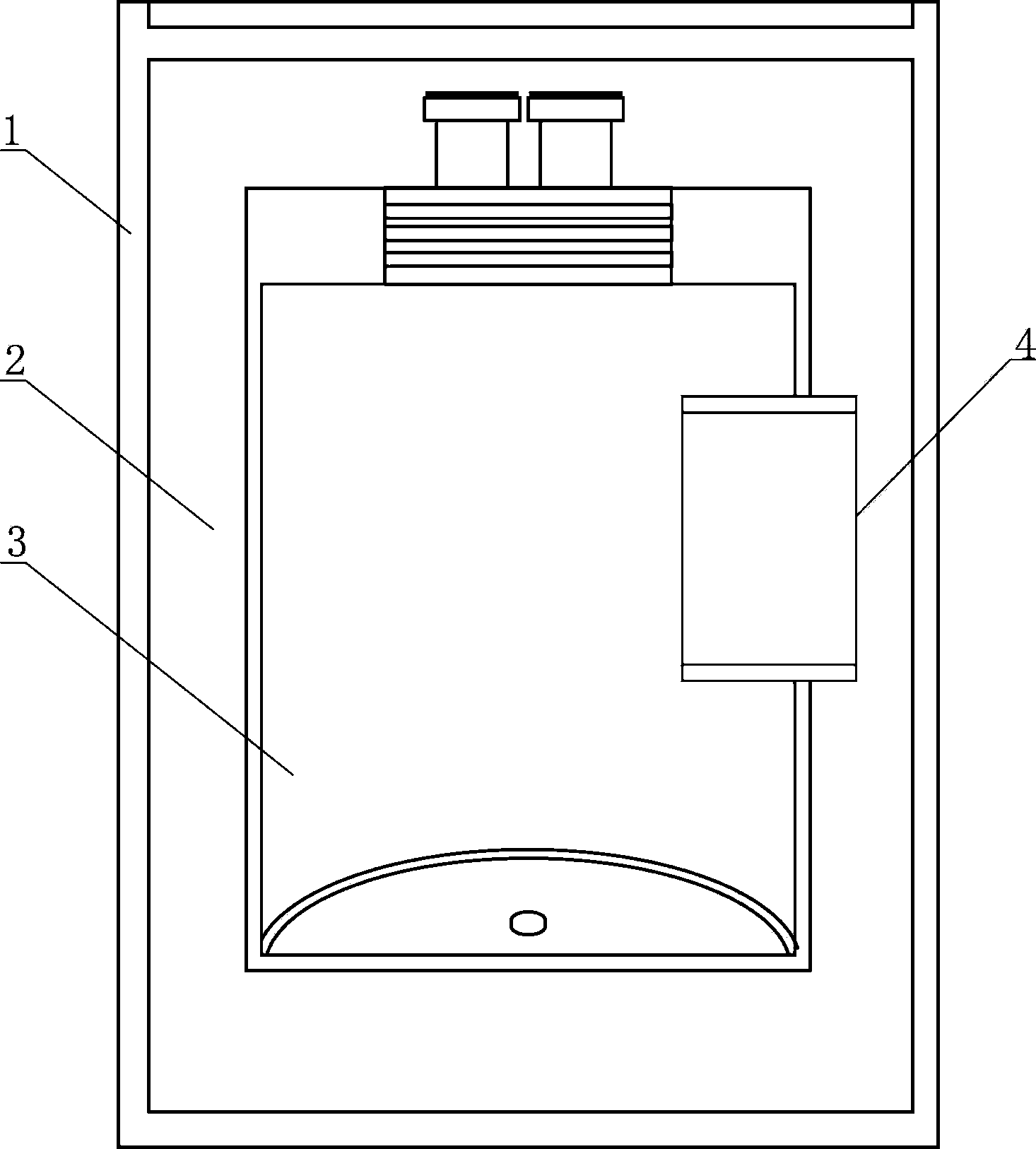

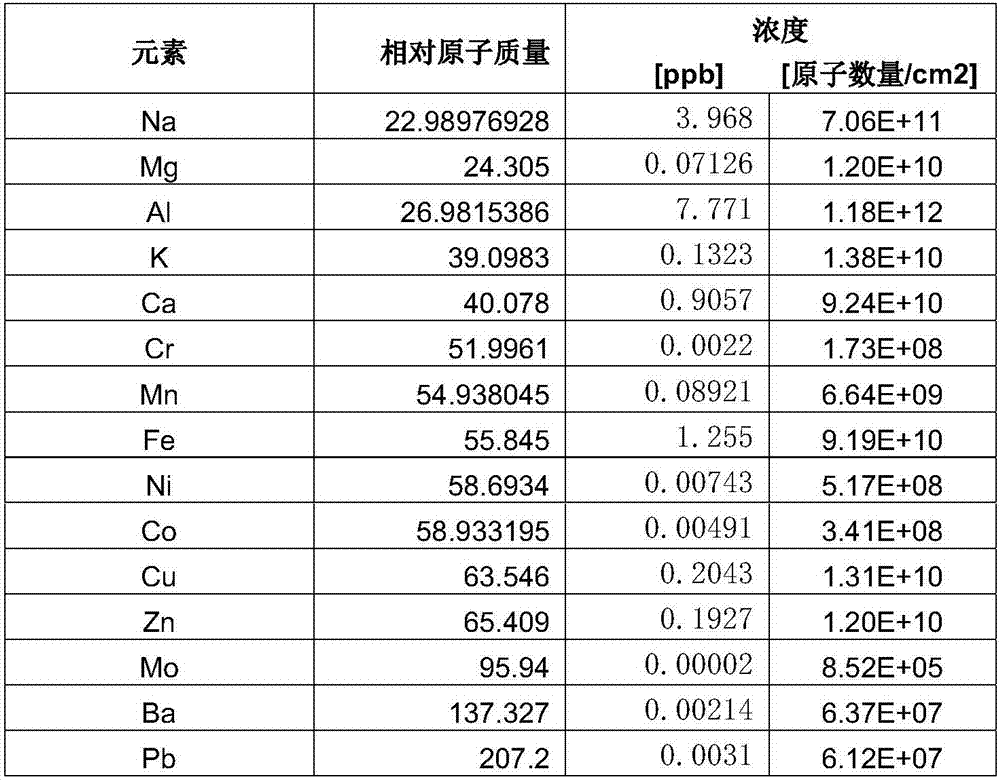

Method for detecting content of metal ions in oxidation film on surface of silicon wafer

InactiveCN107389663AAccurate methodImprove factory pass rateAnalysis by thermal excitationIonPass rate

The invention provides a method for detecting the content of metal ions in an oxidation film on the surface of a silicon wafer. The method is characterized in that two same sample wafers are selected; oxidation treatment is carried out on the surface of one sample wafer, so that the sample wafer having the surface coated with an oxidation film can be obtained; the contents of metal ions on the surfaces of the two sample wafers are detected, and the content of the metal ions in the oxidation film can be obtained based on data difference of the two sample wafers. The method provided by the invention is accurate and effective, realizes all-element and ultramicro precision measurement of the metal ions in the oxidation film indeed, provides scientific test data for a process technology for reducing the introduction of metallic element impurities in a whole production process, meets the requirements of manufacturers during semiconductor manufacturing, and plays an active role in improving the ex factory pass rate of products and lowering the cost of semiconductor component manufacturers.

Owner:TIANJIN ZHONGHUAN ADVANCED MATERIAL TECH

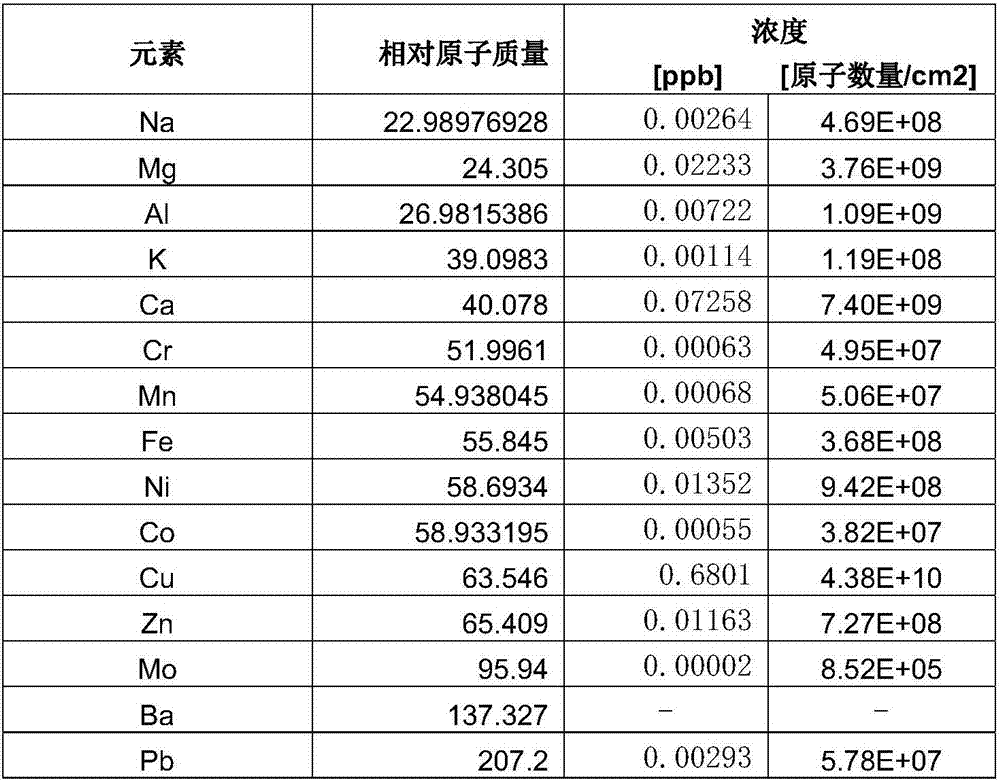

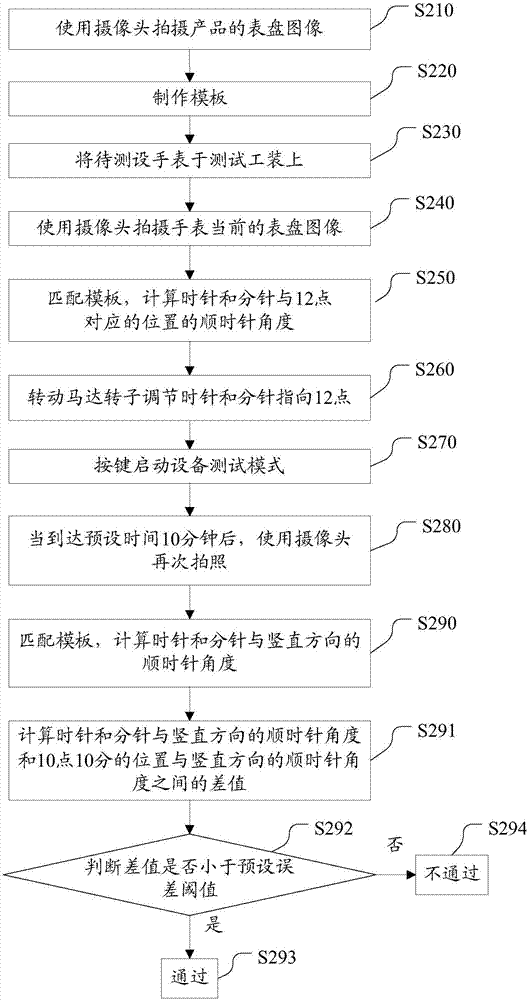

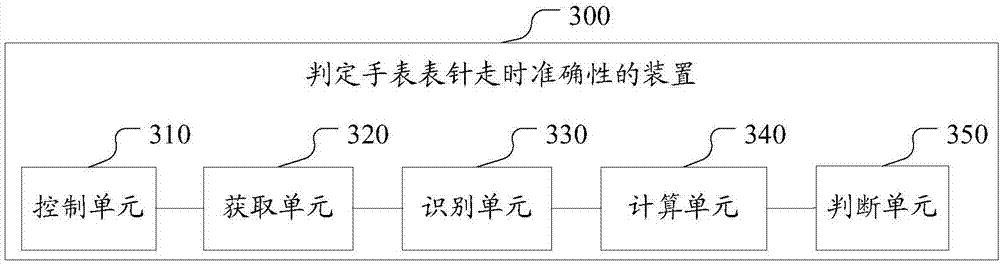

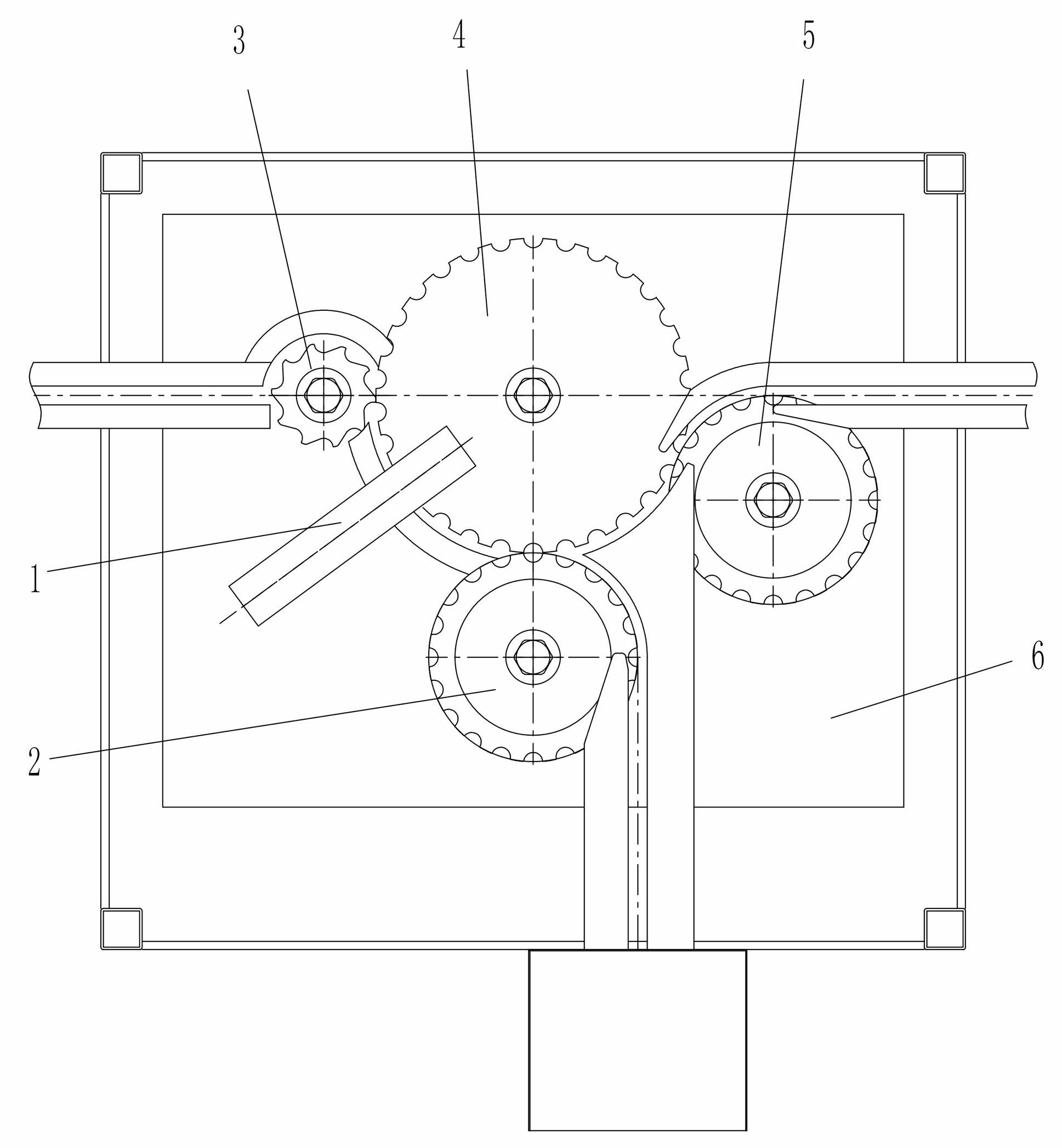

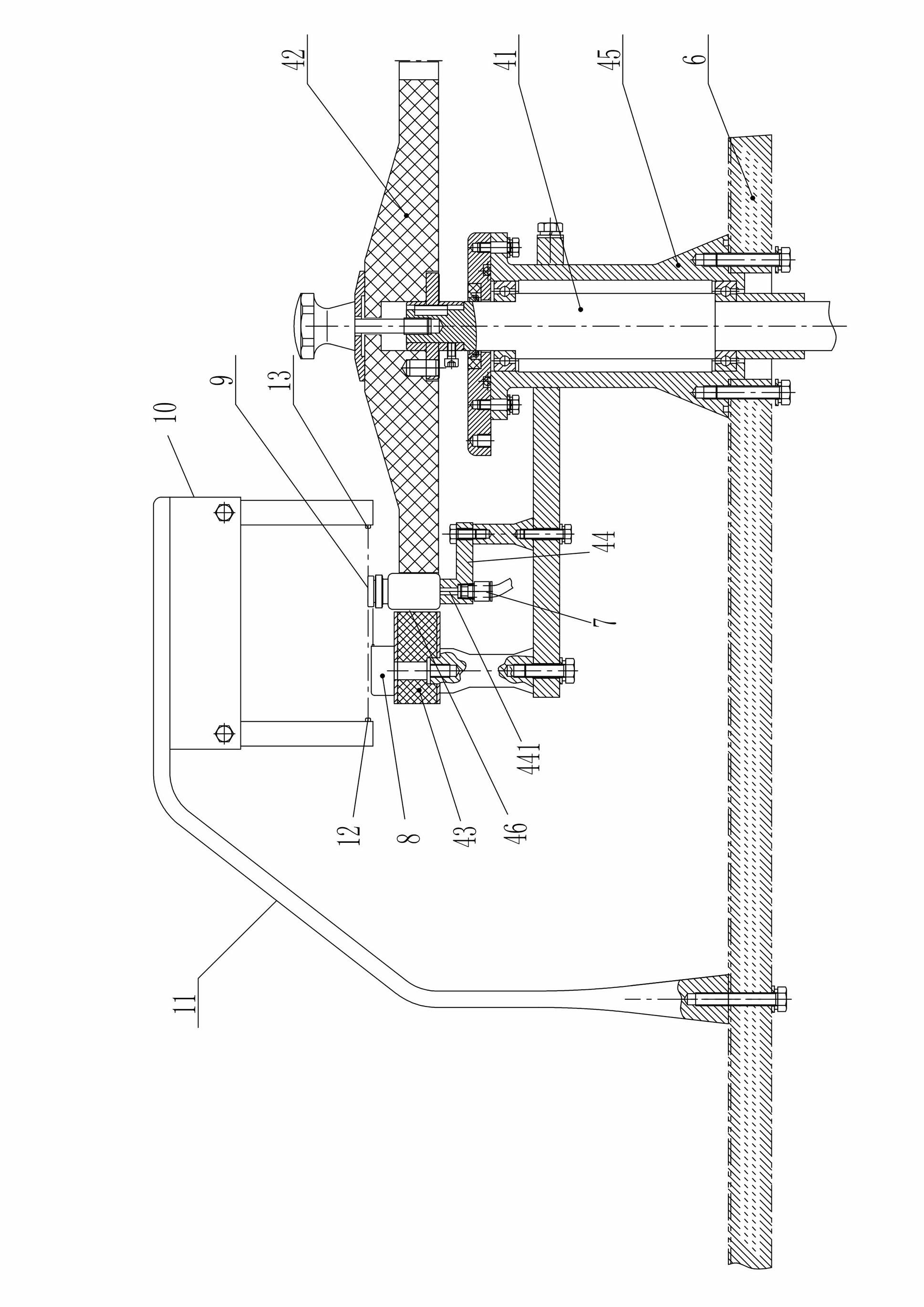

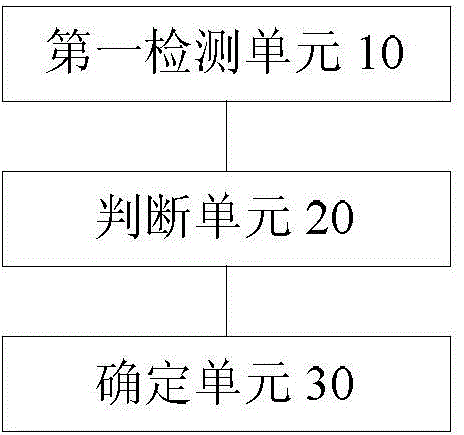

Method, device and system for determining operation accuracy of watch hand

The invention discloses a method, device and system for determining the operation accuracy of a watch hand. The method comprises the steps as follows: controlling the watch hand to rotate for preset time at a preset constant speed from a position corresponding to test starting time; acquiring a first dial plate image collected by a camera at a position where the rotation of the watch hand is finished; identifying the watch hand and a marking position in the first dial plate image according to a watch hand template and a marking position template, and determining the positions of the watch hand and the marking position in the first dial plate image; calculating a first clockwise angle from the position of the watch hand to the marking position; calculating a first difference value of the first clockwise angle and a standard clockwise angle; judging whether the first difference value is greater than a preset error threshold; if so, judging that the operation of the watch hand is not accurate. Therefore, by the scheme, the operation accuracy of the watch hand can be accurately determined, the unqualified watches can be timely detected, and prevented from entering the market, and the ex factory pass rate of the watches is improved.

Owner:GEER TECH CO LTD

Quality detecting device for bottle body plug adding

InactiveCN102590223AImprove factory pass rateOperational impactOptically investigating flaws/contaminationPass rateEngineering

The invention discloses a quality detecting device for bottle body plug adding, which comprises a first detecting assembly, a waste removing assembly and a bottle body conveying assembly. The first detecting assembly and the waste removing assembly are sequentially arranged along the bottle conveying direction of the bottle body conveying assembly, the first detecting assembly comprises a light source emitter and a light source receiver which are oppositely arranged on two sides of the bottle bodies to be detected on the bottle body conveying assembly. The quality detecting device for bottle body plug adding can detect and remove bottle bodies with unqualified plugs, improves ex-factory pass rate of finished products, and has the advantages of being simple in structure, easy to achieve, high in detection precision and the like. For the bottle bodies needing to be conveyed into a cover rolling machine for cover rolling after plug adding, influence on cover rolling operation caused by unqualified bottle body plug adding further can be avoided.

Owner:TRUKING TECH LTD

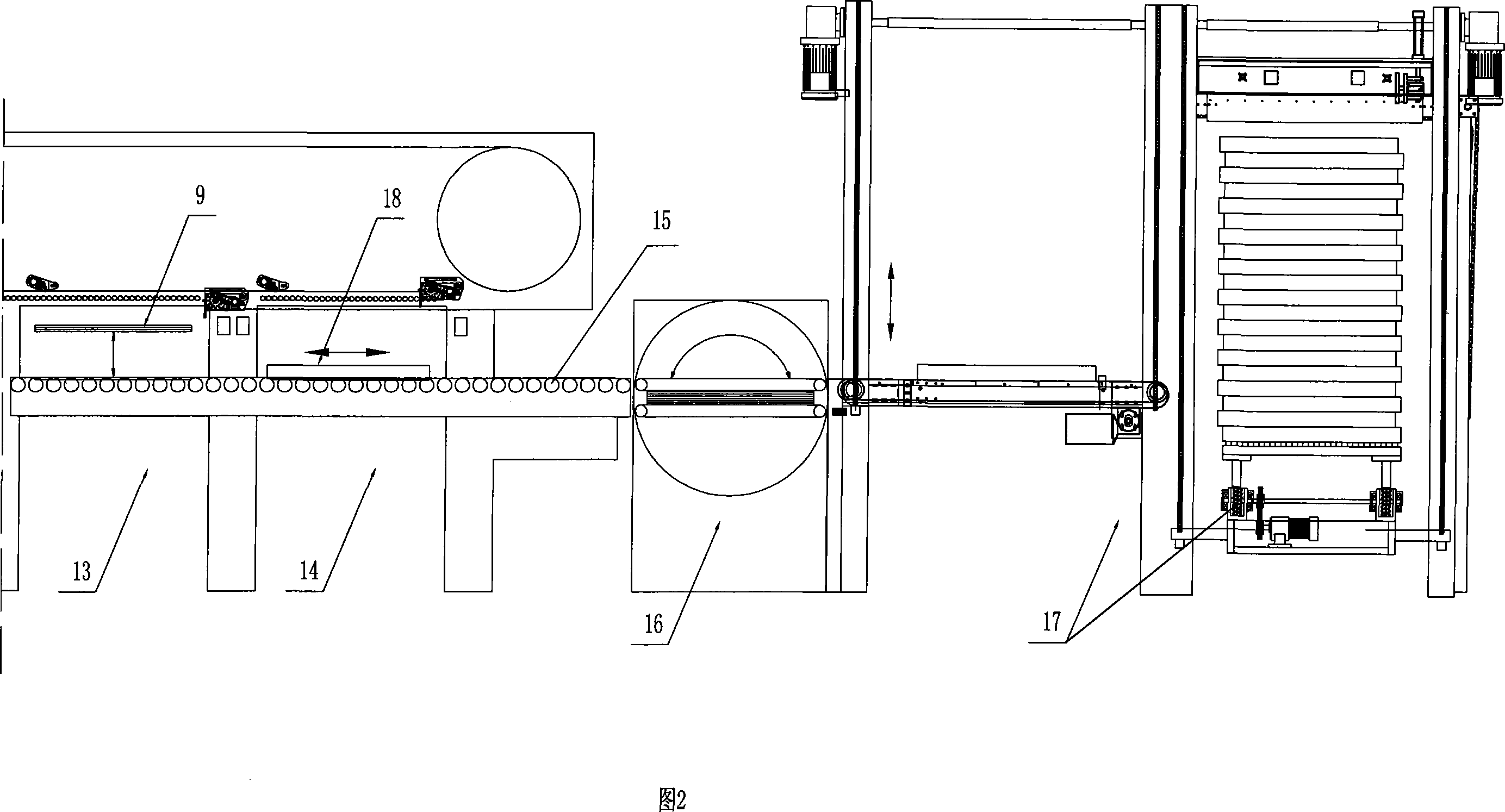

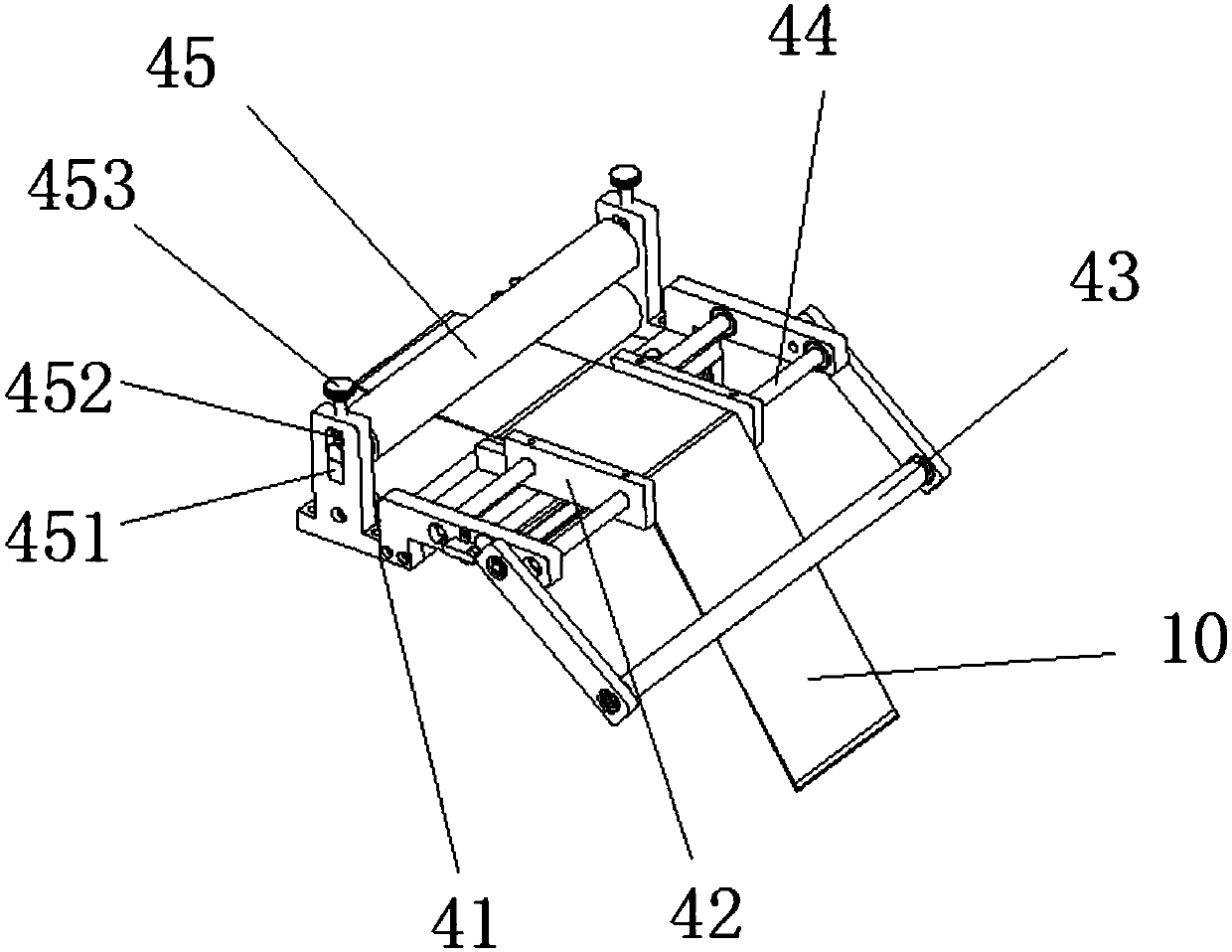

A method for automatically tidying and selecting papers

The invention discloses a method for automatically sorting and classifying paper, and belongs to a quality detection and sorting method of a paper making process. The purpose is to provide the method that paper is decomposed into a single piece of paper to detect the appearance quality, and the single piece of detected paper is classified and respectively counted by adopting a linking automatic equipment, and then sorted the ream output or the quire output. The method mainly comprises the following steps: quires of flat paper are outputted by utilizing a paper conveying machine in the form of a single piece of flat paper; at the outlet end of the paper conveying machine, the appearance quality of the paper is detected by utilizing a computer visual processing system; the appearance quality of the paper is detected by utilizing a computer visual processing system; the paper is counted and selected; the ream and the quire are sorted to qualified paper; reams or quires of paper are outputted. The invention can be suitable for the quality detection and the sorting and the classifying of various pieces of paper in the paper making production.

Owner:CHINA BANKNOTE PRINTING & MINTING

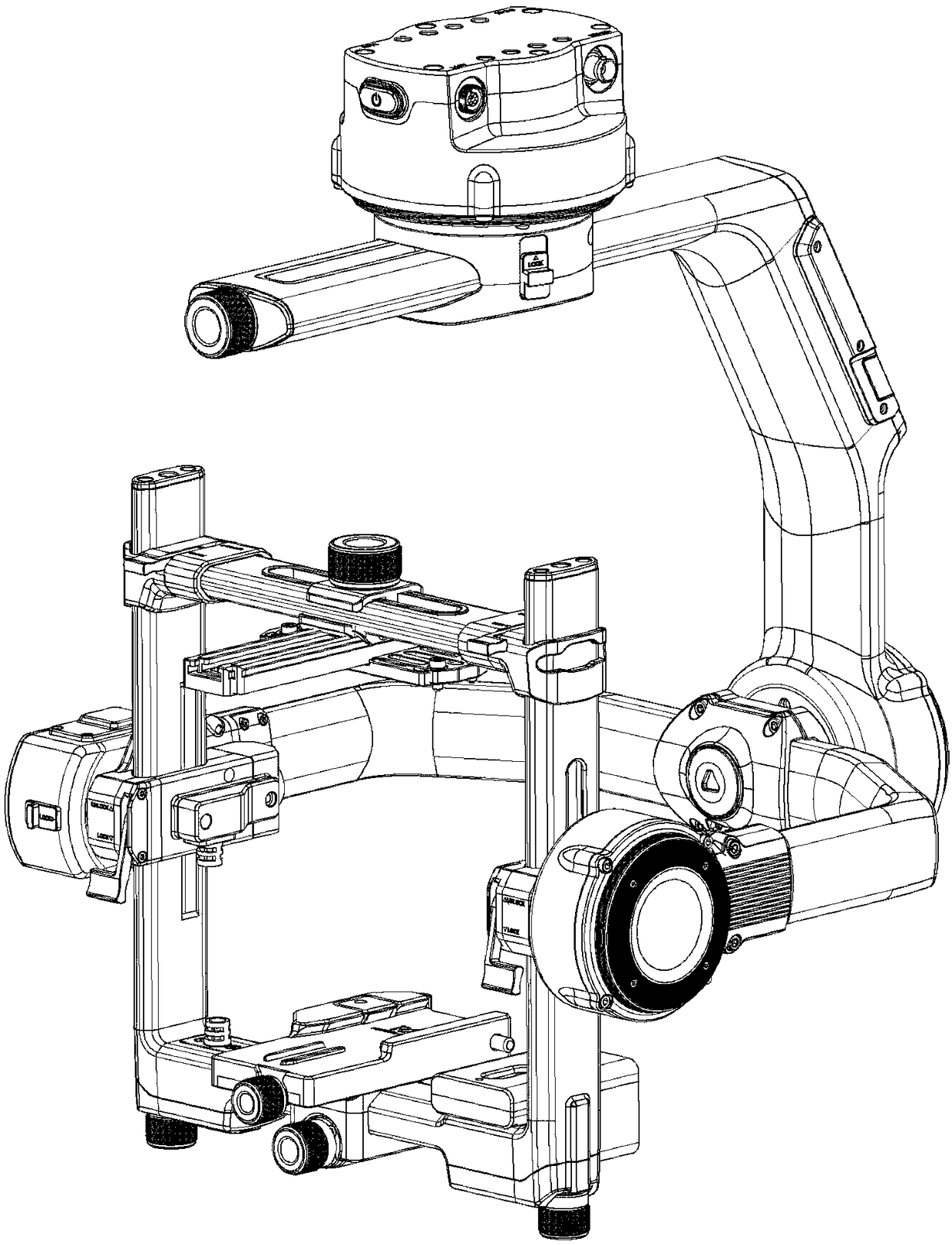

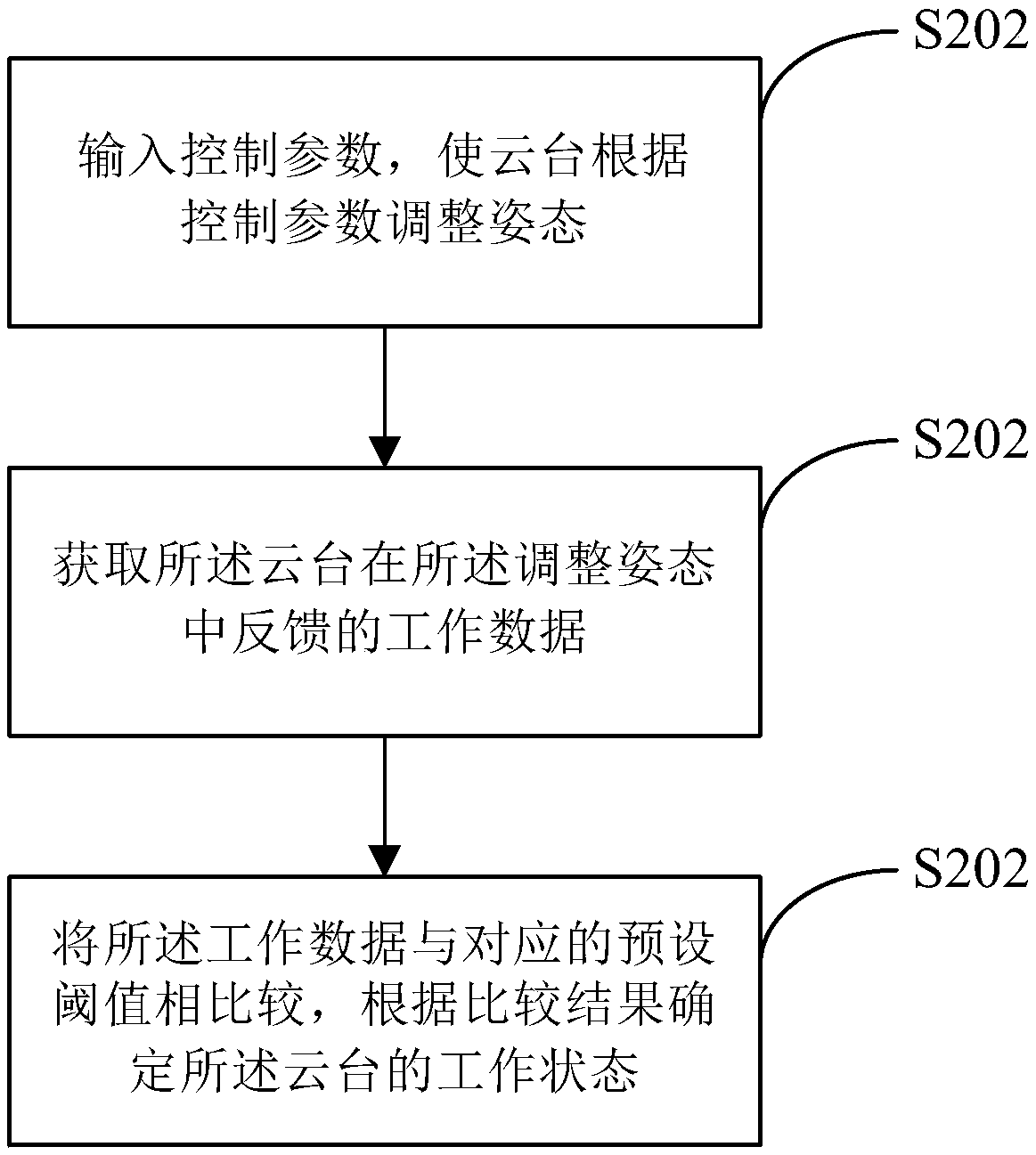

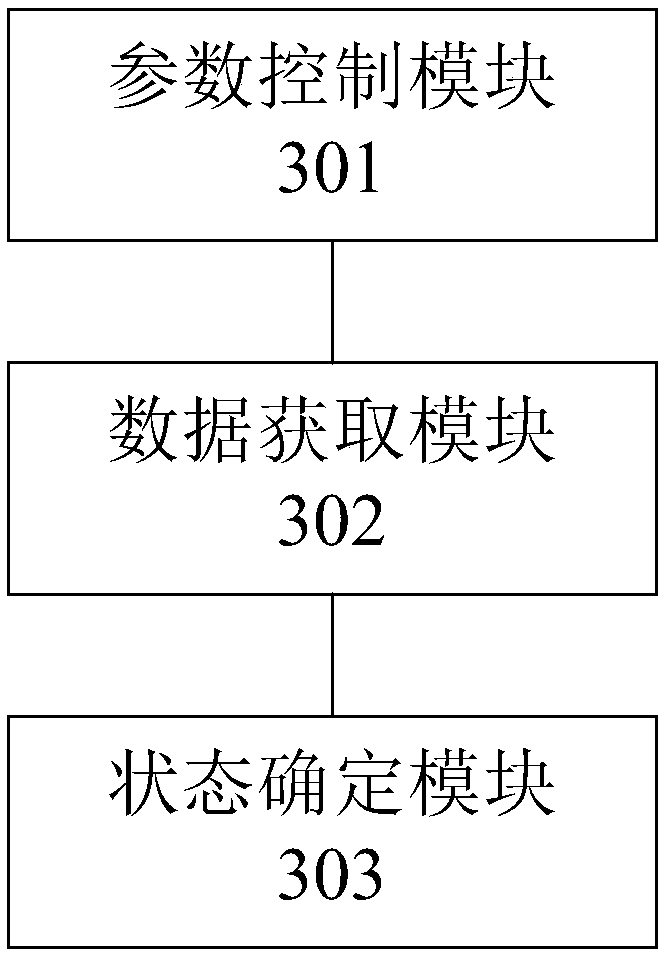

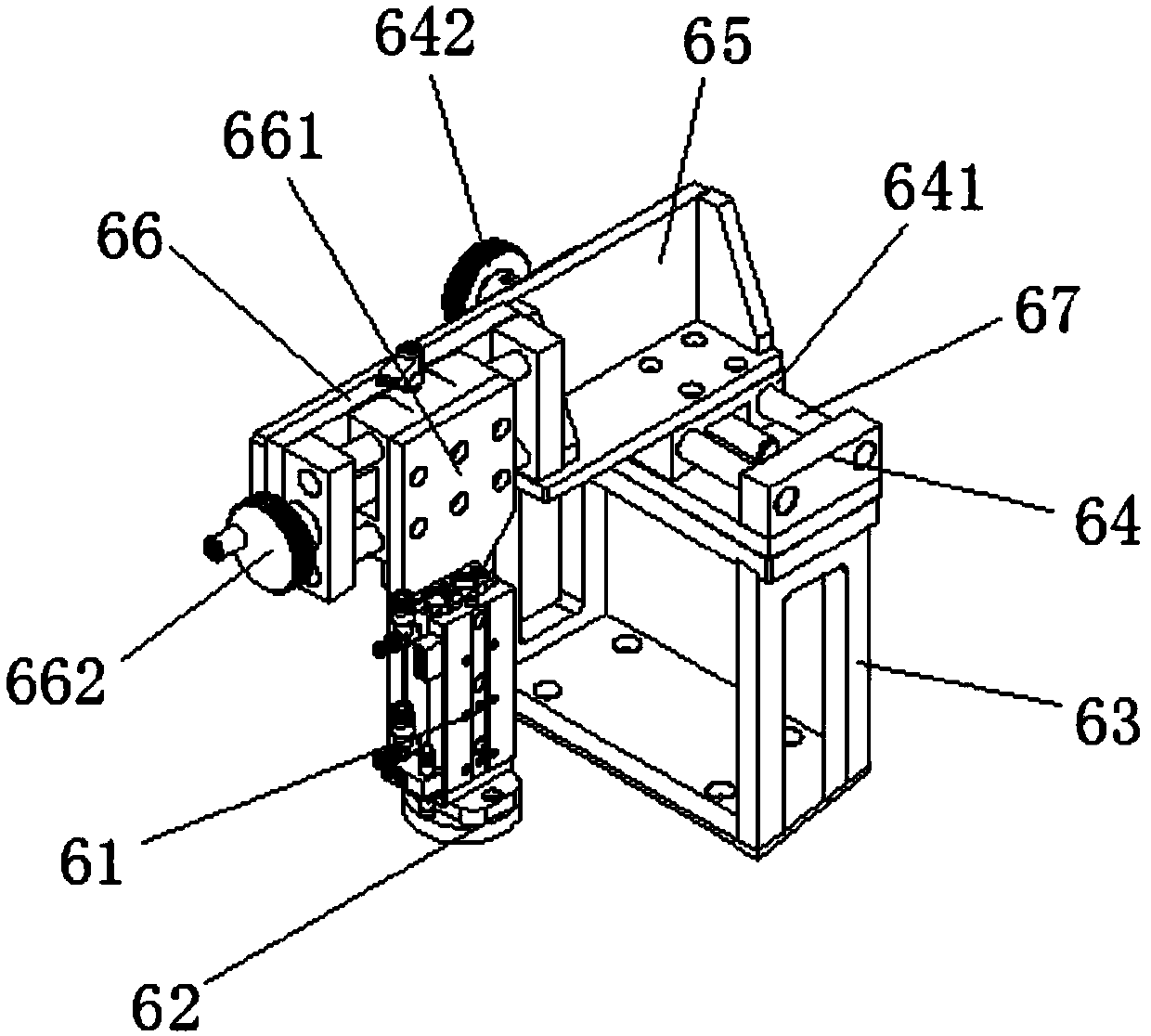

Reliability testing method and device for cradle head

InactiveCN109313439AImprove factory pass rateProgramme controlElectric testing/monitoringControl parametersOperational reliability

A reliability testing method and device for a cradle head, the reliability testing method for a cradle head comprising: inputting a control parameter such that the cradle head adjusts posture according to the control parameter (S202); acquiring working data that is fed back by the cradle head during during posture adjustment (S204); and, comparing the working data with a corresponding preset threshold value, and according to the comparison result, determining the working state of the cradle head (S206). The reliability testing method for a cradle head may test the operational reliability of acradle head.

Owner:SZ DJI TECH CO LTD

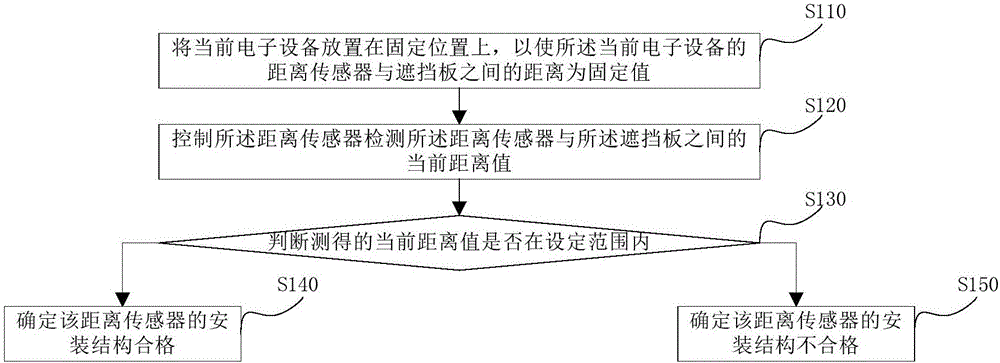

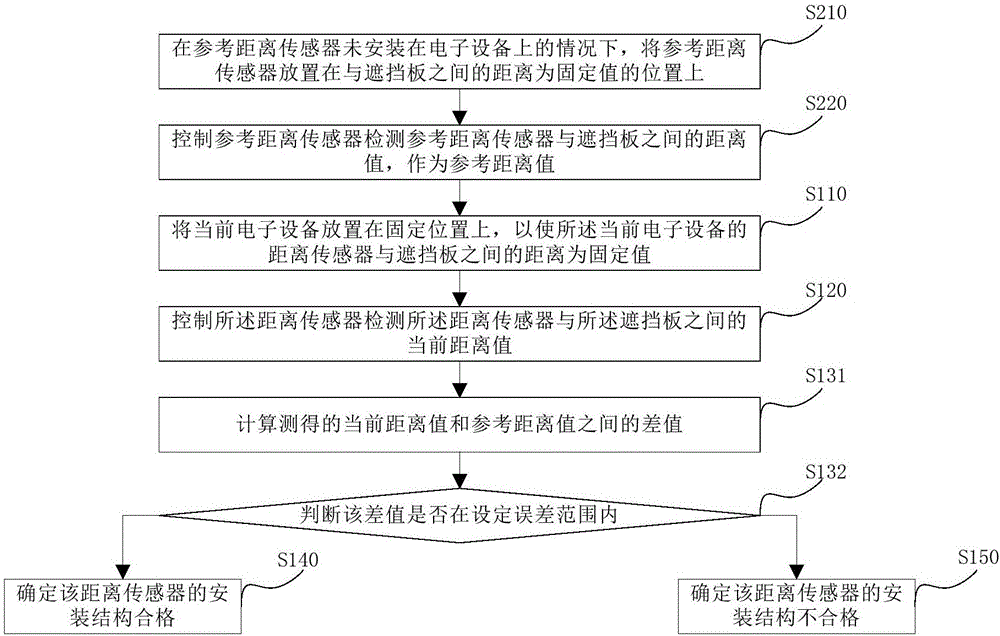

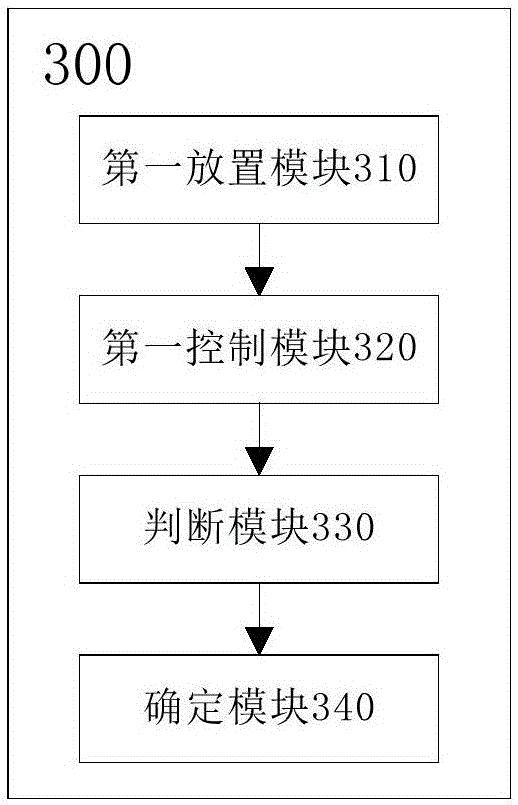

Detecting method and device for installation structure of distance sensor of electronic equipment

InactiveCN106842224AImprove factory pass rateElectromagnetic wave reradiationSimulationDevice placement

The invention discloses a detecting method and device for an installation structure of a distance sensor of electronic equipment. The detecting method for the installation structure comprises the steps of placing the current electronic equipment in a fixed position, in order to make the distance between the distance sensor of the current electronic equipment and a baffle plate a fixed value, controlling the distance sensor to detect a current distance value between the distance sensor and the baffle plate, and judging whether or not the current distance value measured is in a setting range, and if yes, the installation structure of the distance sensor is determined to be qualified. In this way, the electronic equipment controls the distance sensor to detect the distance value between the same shelter and the distance sensor which have the same distance in the same environment, by judging whether or not a detecting result is in the setting range, whether or not the installation structure of the distance sensor on the electronic equipment is qualified can be detected, and therefore the factory qualification rate of electronic products is increased.

Owner:BEIJING PICO TECH

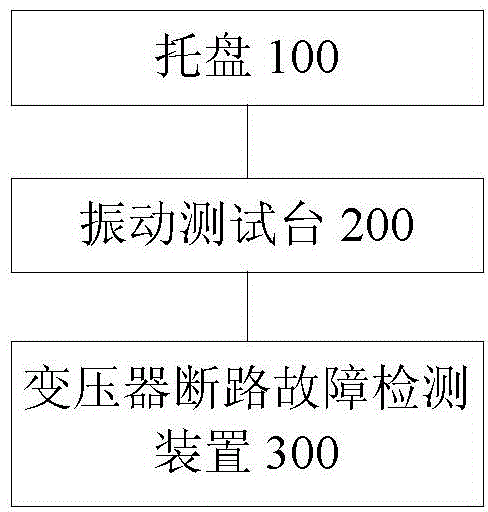

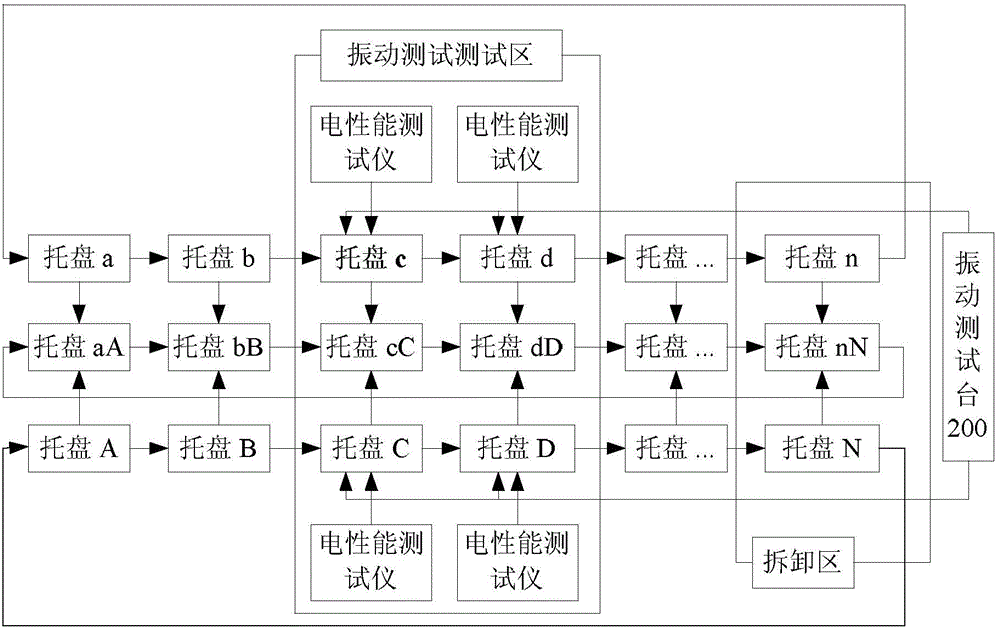

Method, device and system for detecting open-circuit faults of transformers

The invention discloses a method, a device and a system for detecting open-circuit faults of transformers. The method for detecting the open-circuit faults of the transformers includes detecting output voltage values and / or output current values of the transformers; judging whether the output voltage values and / or the output current values of the transformers are abnormal or not; determining that the transformers are disqualified if the output voltage values and / or the output current values of the transformers are abnormal. Rated voltages are carried by primary components of the transformers, and rated loads are connected to secondary components of the transformers. The method, the device and the system have the advantages that the problem of difficulty in detecting 'apparently disconnected but actually connected' and 'intermittent' open-circuit faults of transformers in the prior art can be solved, and effects of increasing the delivery qualified rate of the transformers can be realized.

Owner:GREE ELECTRIC APPLIANCES INC

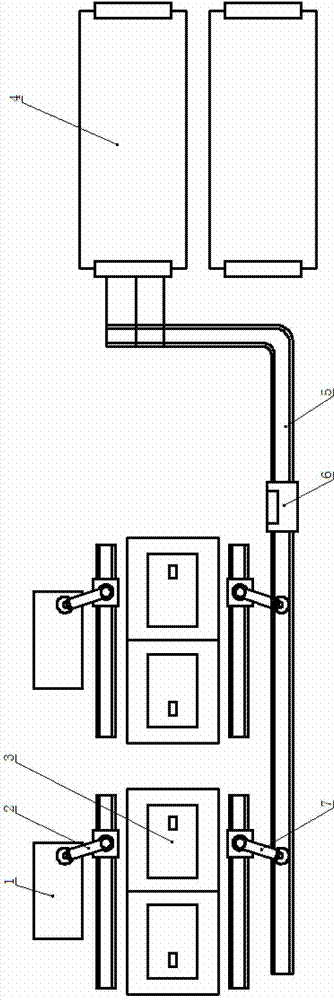

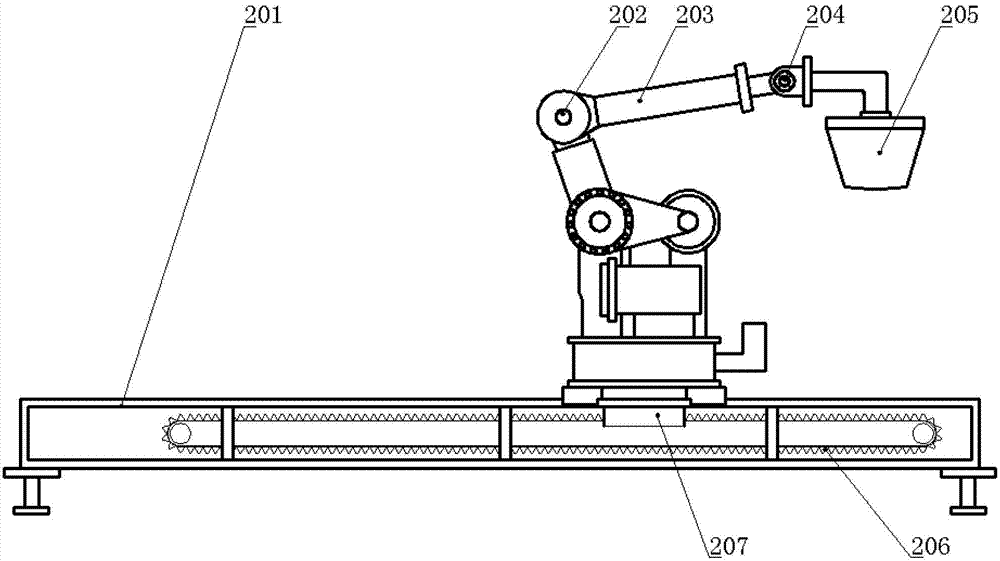

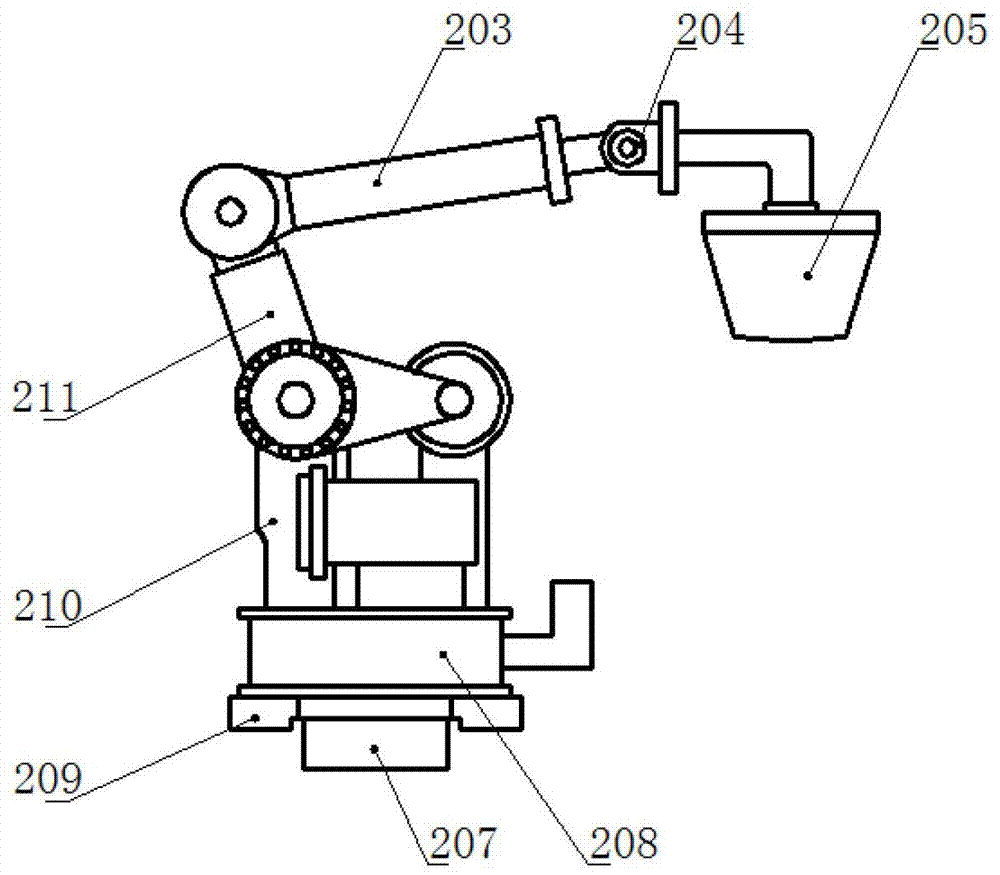

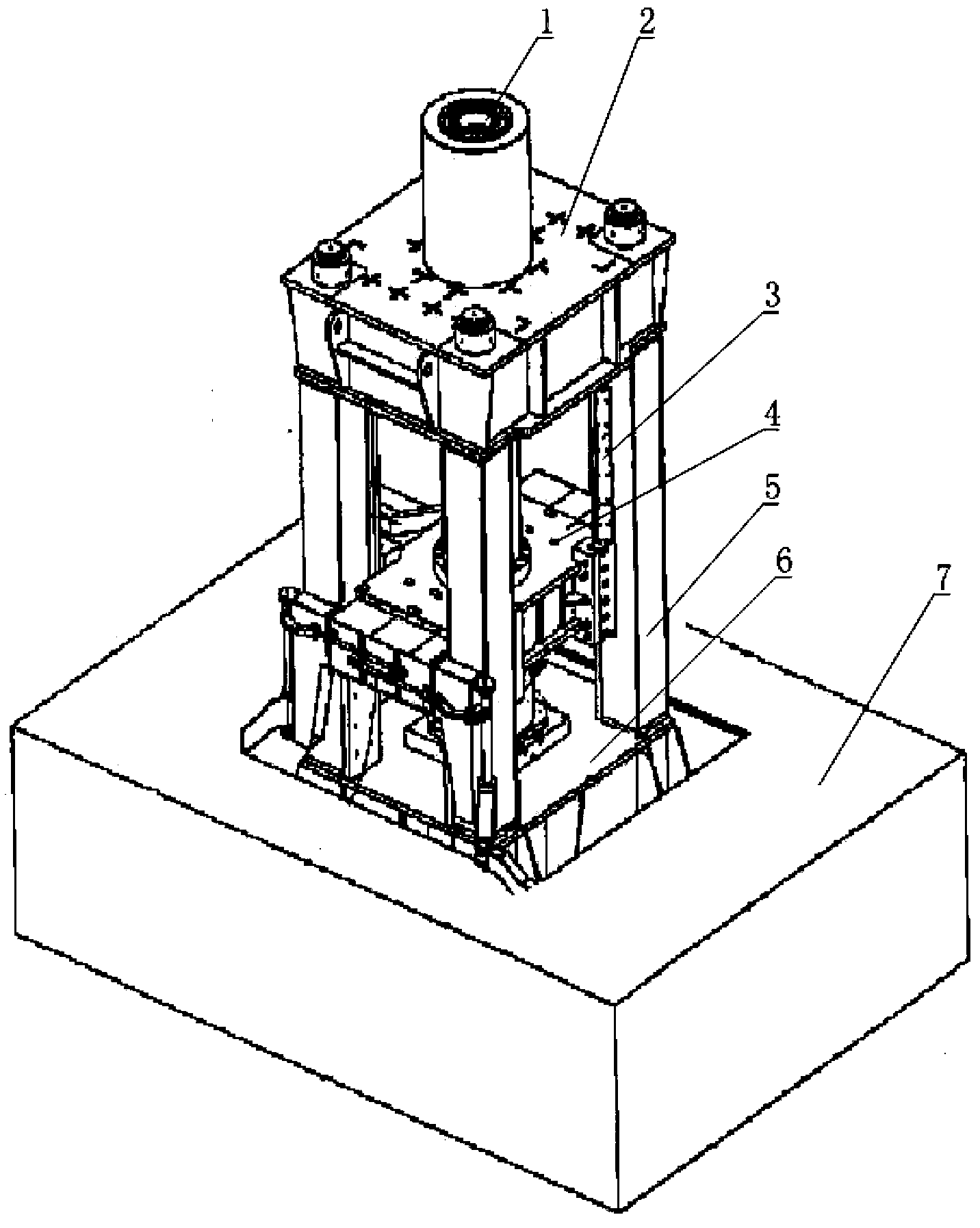

Double-station hydraulic die forging machining system and machining process

ActiveCN103111571AAvoid damageMeet the mechanical performance requirementsForging/hammering/pressing machinesForging press detailsRobot handMachine

The invention relates to a dual-station hydraulic die forging machining system and a machining process. The machining system comprises a heat preservation furnace, a forging machine, a melt feed manipulator, a product grabbing manipulator, a transferring rail and a storage frame. The heat preservation furnace is arranged at one side of the forging machine, and the melt feed manipulator installed between the forging machine and the heat preservation furnace scoops melt from the heat preservation furnace and conveys to the forging machine for machining. The other side of the forging machine is provided with the transferring rail, and the product grabbing manipulator is installed between the forging machine and the transferring rail. The machining system can achieve multi-station full-automatic production, and is simple in layout, easy and convenient to operate, capable of qualifying work of two forging machines when only one operator is needed, capable of making use of resources in the greatest degree and saving labor cost, meanwhile capable of obviously improving production efficiency, stable in operation, and reliable in quality.

Owner:TIANJIN NANUO MACHINERY MFG

Glass foreign bubble detecting method

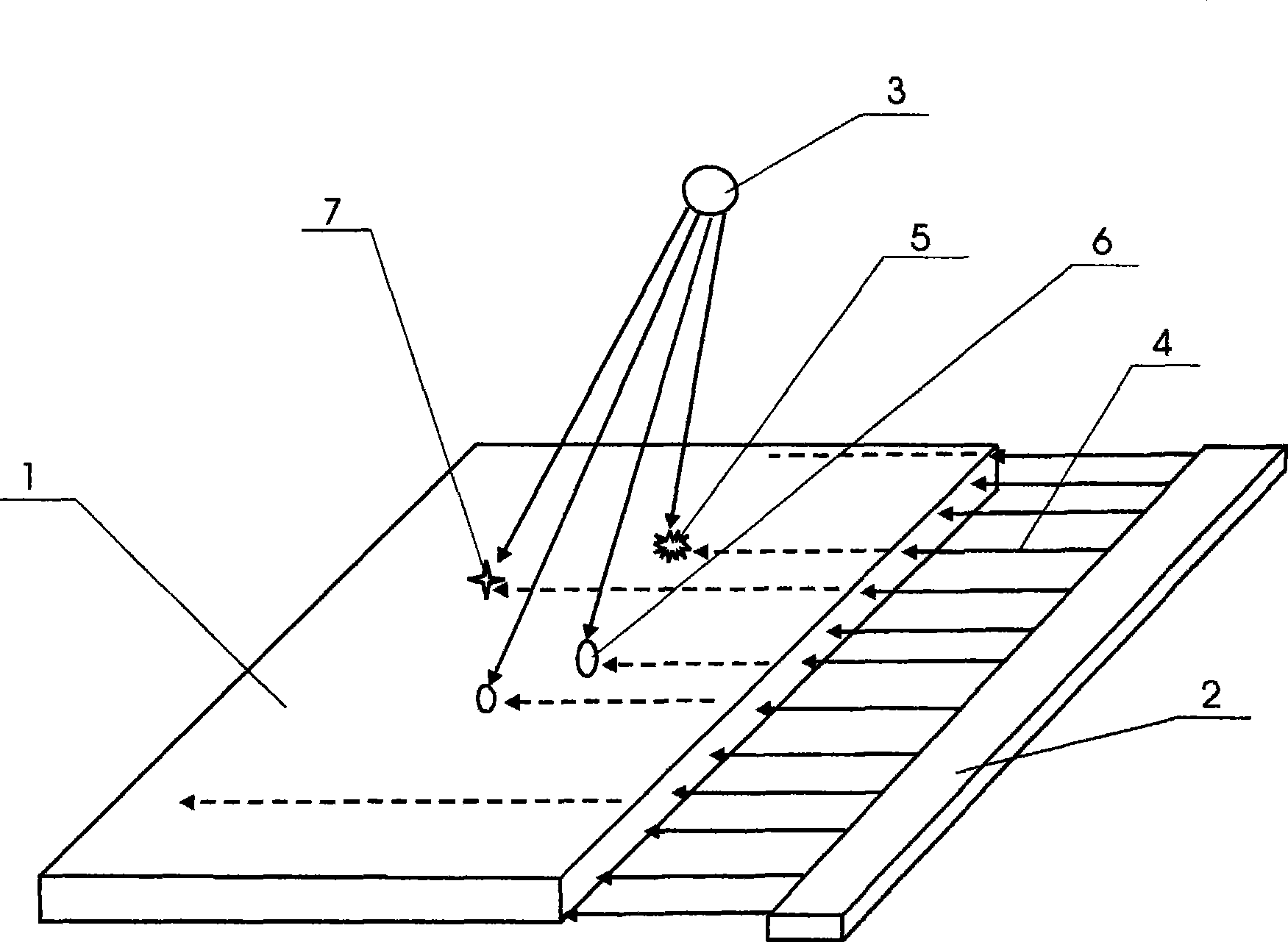

InactiveCN101424646AReliable detectionImprove reliabilityMaterial analysis by optical meansForeign matterGlass foreign body

The invention relates to a method for detecting foreign matters and bobbles in glass. Firstly, after glass to be detected is laid or erected and is stably placed, a light source is arranged at one side of the glass to be detected; then rays of the light source are transmitted into the glass to be detected from a positive transdermal shadow angle at the side of the glass to be detected and are scanned by people through adopting a visual check method or adopting a linear scanning head of a computer; according to factors, i.e. whether the transmitted rays into the glass to be detected are blocked or changed into other transmission directions, the defects of the glass with foreign matters, bobbles, nickel purite, and the like can be detected.

Owner:樊晖

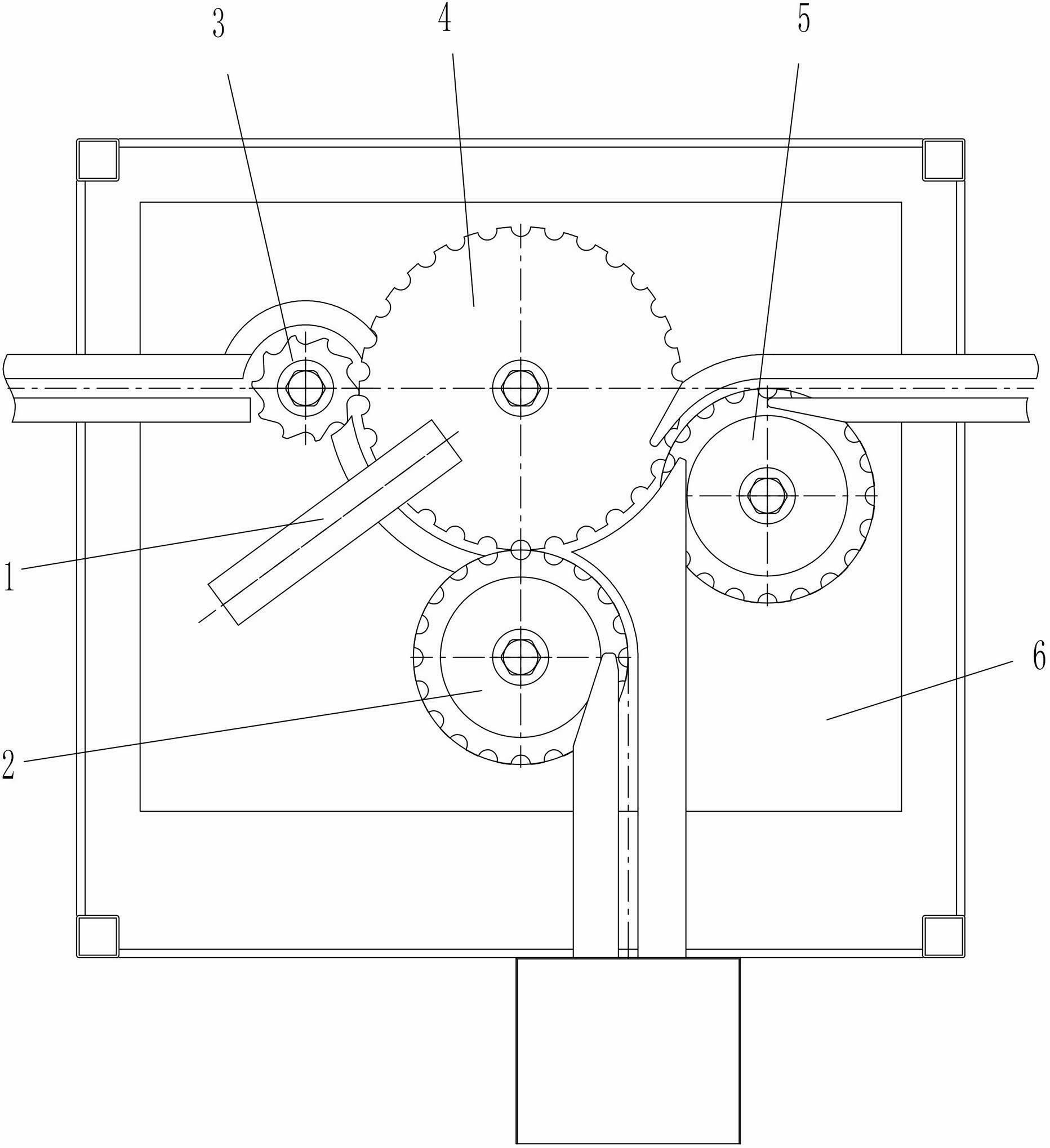

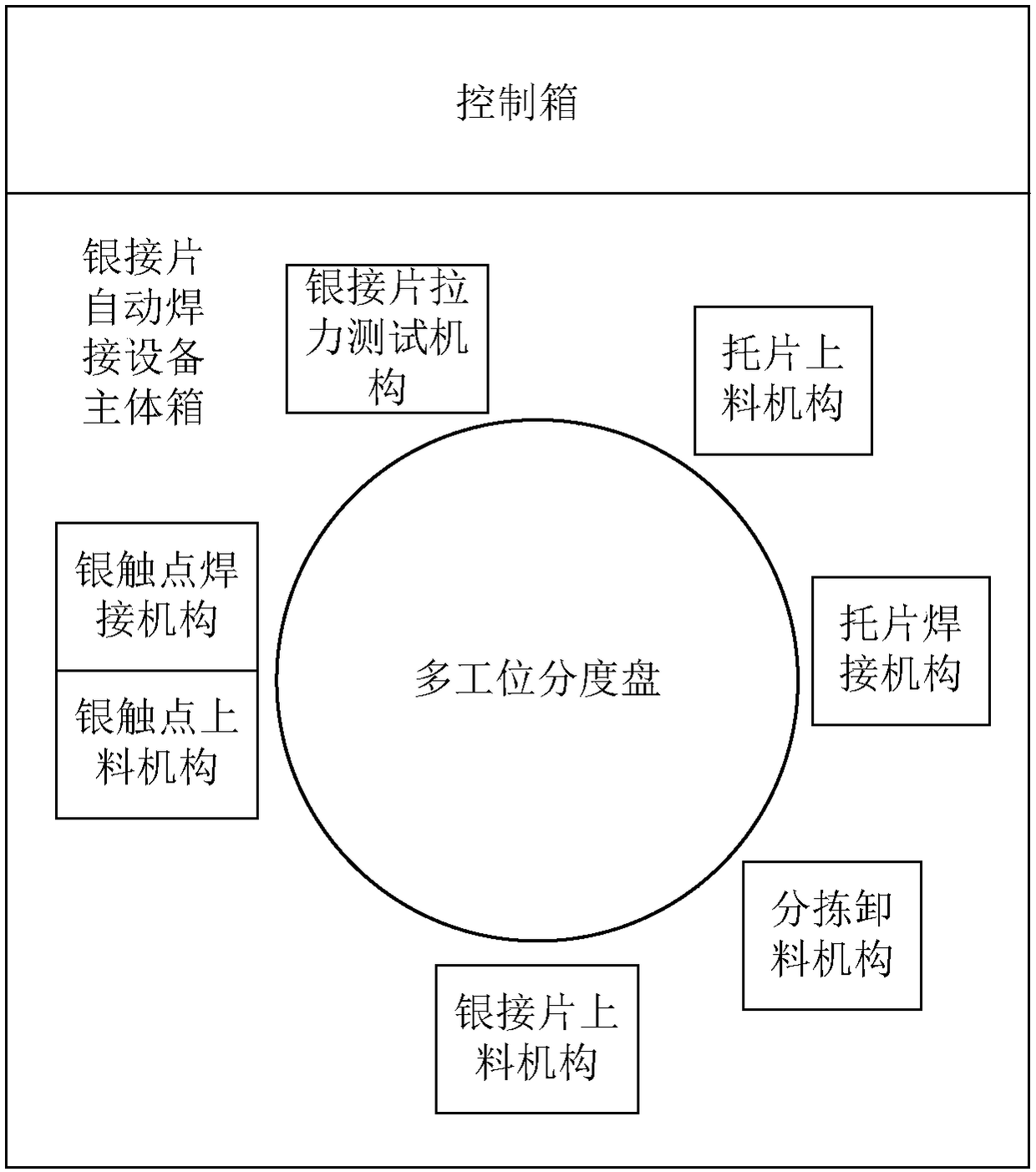

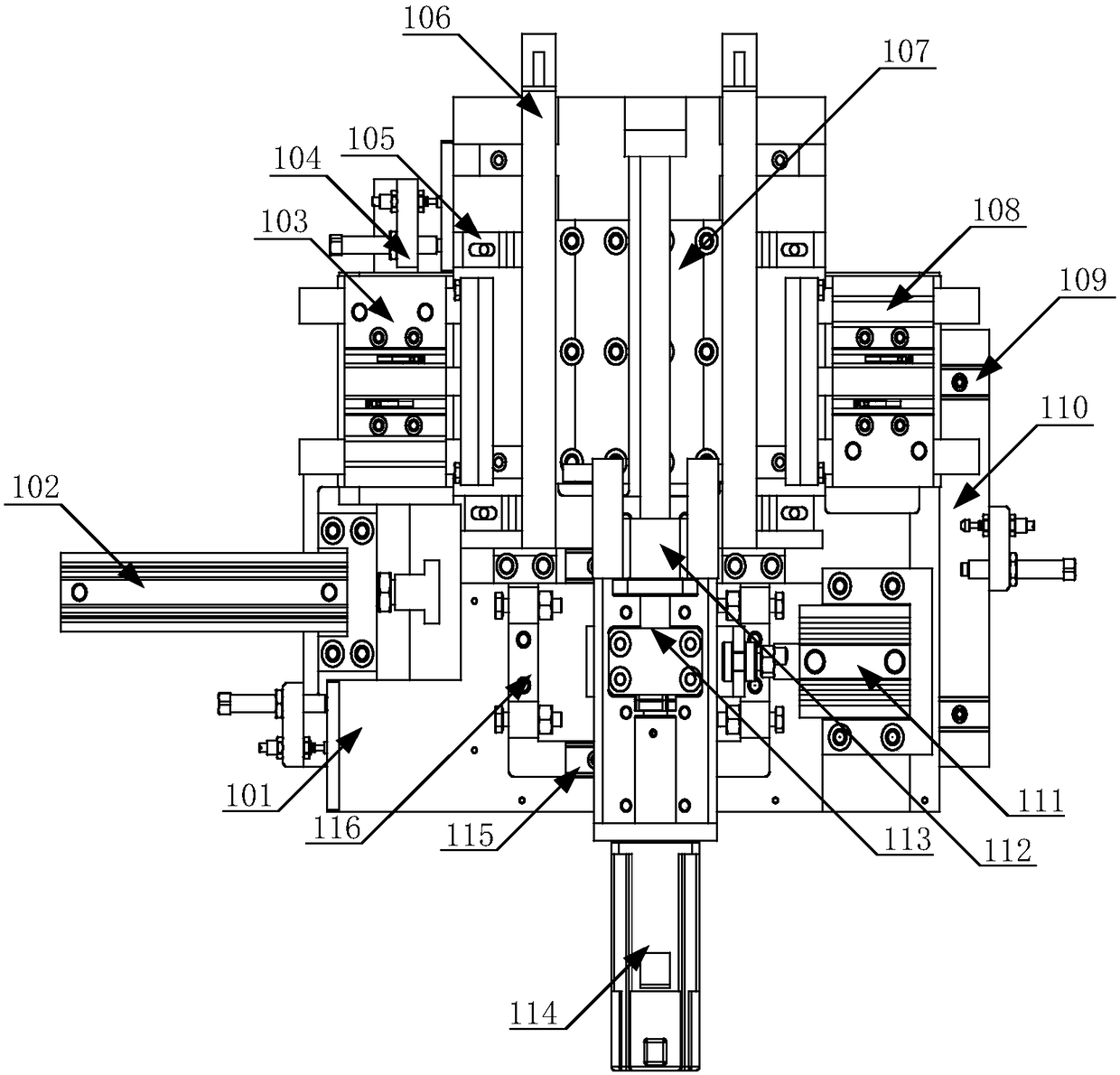

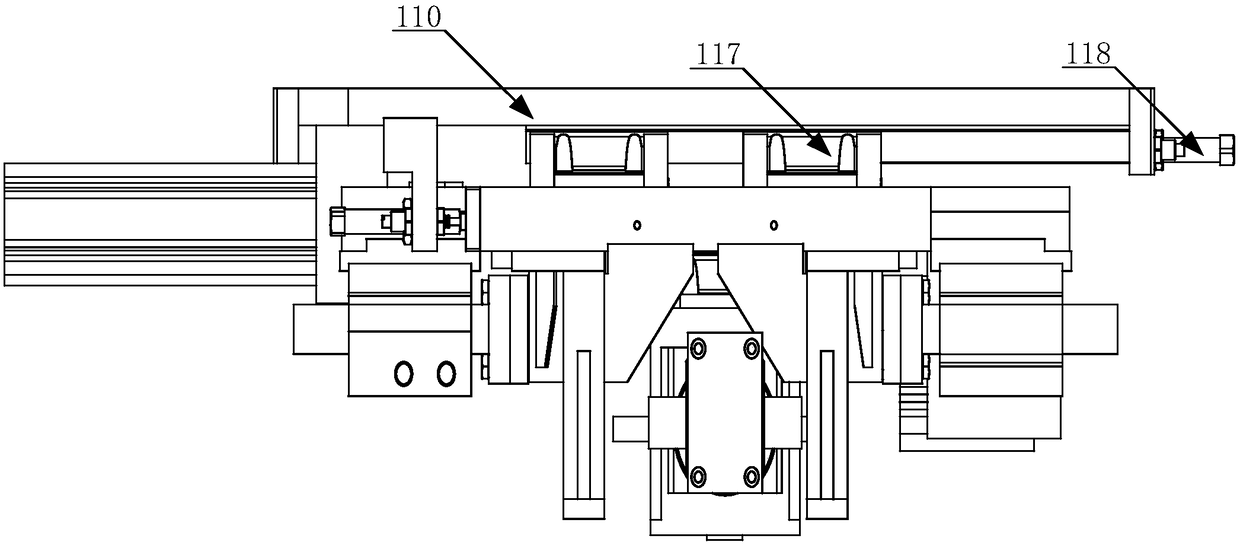

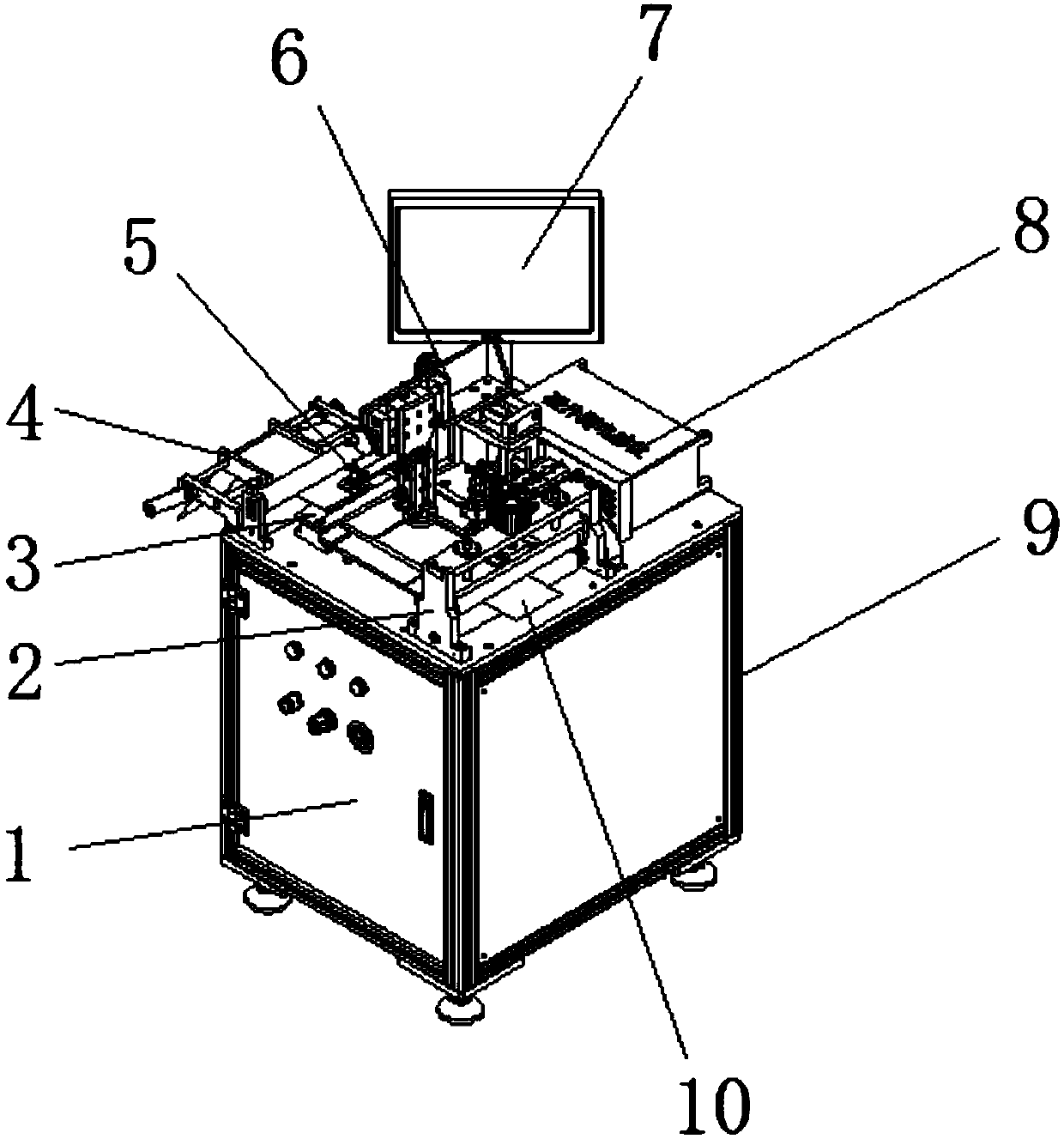

Silver contact chip automatic-welding equipment

ActiveCN108422072AImprove running accuracyWon't wear outWelding/cutting auxillary devicesAuxillary welding devicesEngineeringProduction risk

The invention discloses silver contact chip automatic-welding equipment which comprises a main box of the silver contact chip automatic-welding equipment and a control box, wherein the control box isconnected with the main box of the silver contact chip automatic-welding equipment; the main box of the silver contact chip automatic-welding equipment is instituted by a multi-station indexing plateas well as a silver contact chip feeding mechanism, a silver contact point feeding mechanism, a silver contact point welding mechanism, a silver contact chip tension testing mechanism, a support sheetfeeding mechanism, a support sheet welding mechanism and a sorting-discharging mechanism which are positioned around the multi-station indexing plate and sequentially arranged according to the clockwise direction; one and the same feeding mechanism is selected as the silver contact chip feeding mechanism and the support sheet welding mechanism; and one and the same electrode rotation welding mechanism is selected as the silver contact point welding mechanism and the support sheet welding mechanism. By adoption of the silver contact chip automatic-welding equipment provided by the invention, the production of silver contact chips can be automatically completed; the automation degree of the silver contact chip automatic-welding equipment can be greatly improved; the product quality and theproduction efficiency can be improved; and the production risk of an enterprise can be further reduced.

Owner:成都成焊焊接设备有限公司

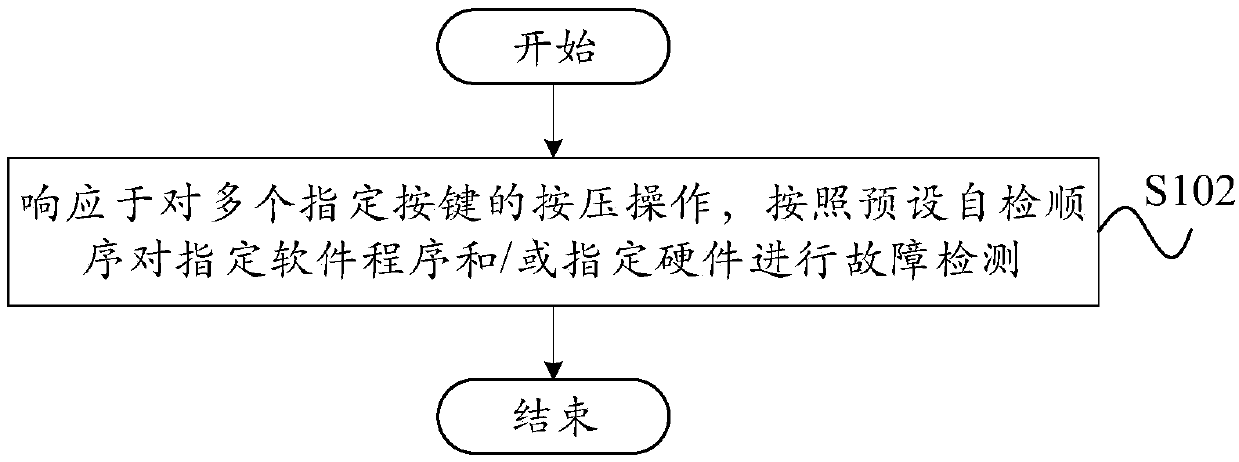

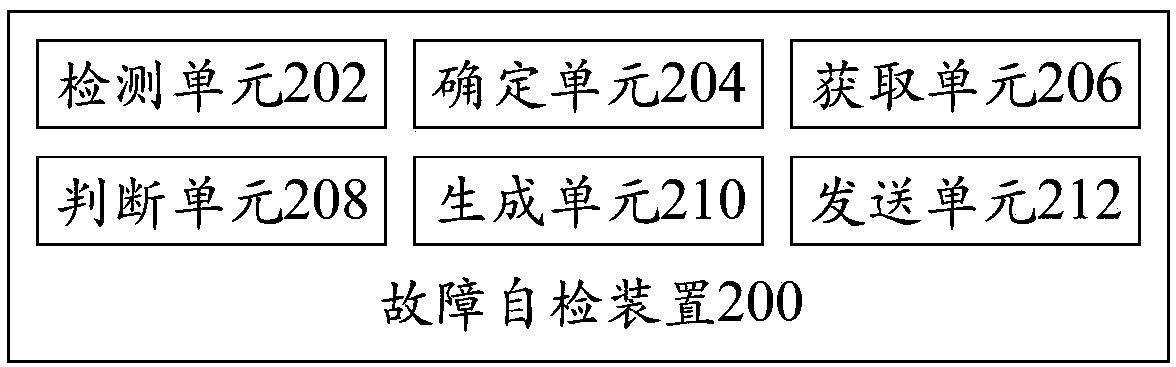

Fault self-checking method and device, electrical device and computer readable storage medium

PendingCN110096394AImprove accuracyImprove reliabilityDetecting faulty hardware by power-on testElectrical testingComputer scienceSelf checking

The invention provides a fault self-checking method and device, an electrical device and a computer readable storage medium, wherein the method comprises the steps of carrying out the fault self-checking on a specified software program and / or a specified hardware according to a preset self-checking sequence in response to the pressing operation of a plurality of specified keys. Through the technical scheme of the invention, the efficiency and reliability of the factory inspection are improved, and the possibility of missed inspection during the inspection process can be effectively reduced.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

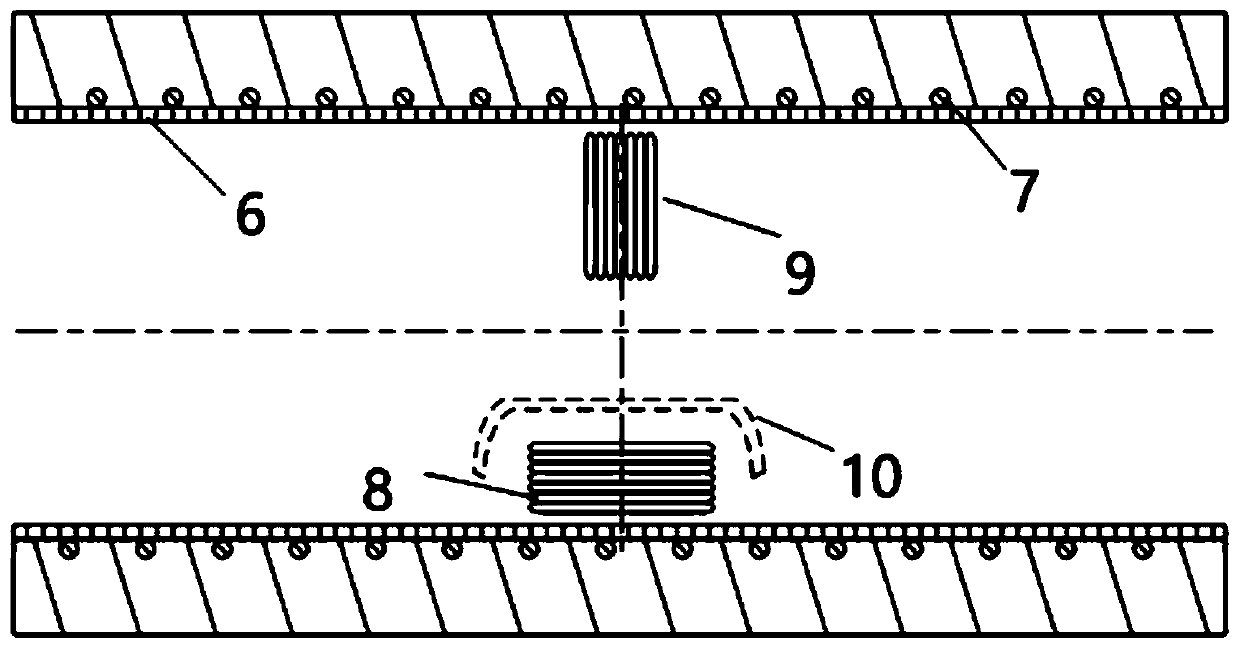

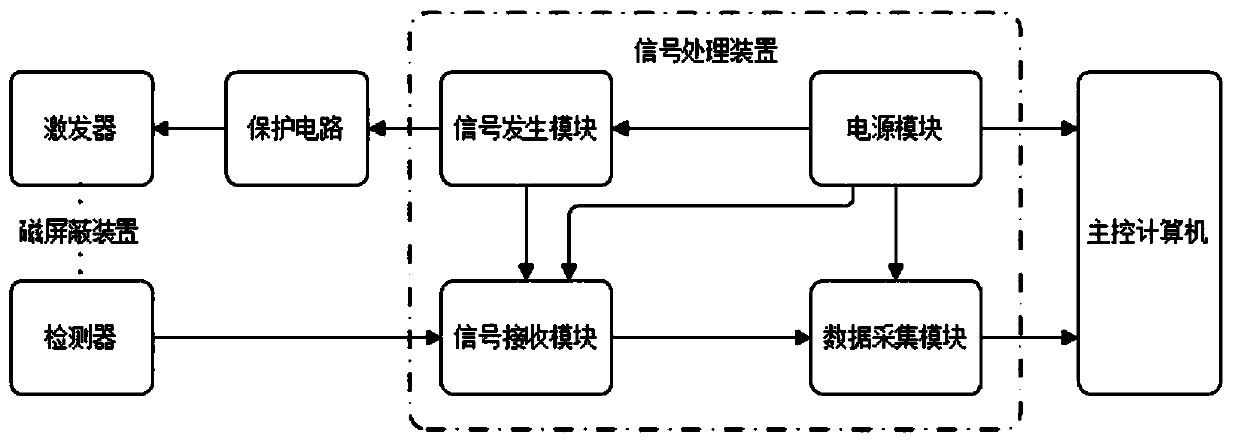

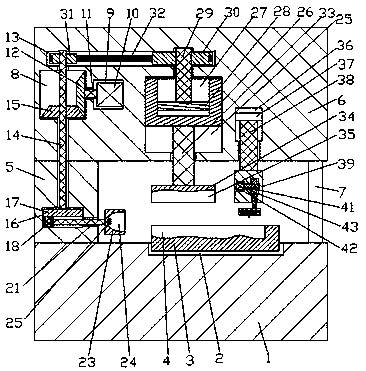

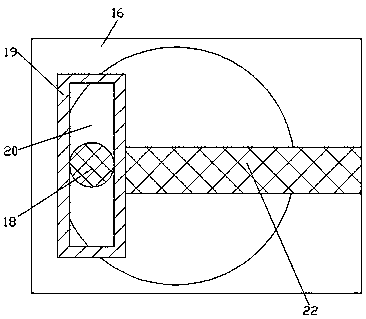

PCCP (prestressed concrete cylinder pipe) pipe broken wire detection equipment based on orthogonal electromagnetic principle

InactiveCN110346838ARealize non-destructive testingImprove efficiencyElectric/magnetic detectionAcoustic wave reradiationPre stressEngineering

The invention discloses PCCP (prestressed concrete cylinder pipe) pipe broken wire detection equipment based on an orthogonal electromagnetic principle. The equipment comprises an exciter, a detector,a protection circuit, a signal processing device and a moving device, wherein the moving device is convenient for carrying the detection device; the exciter and the detector are orthogonally arranged; the protection circuit is used for protecting the exciter; the exciter is driven by a low-frequency sinusoidal signal to generate an alternating magnetic field, and the detector is used for receiving a magnetic field signal caused by an induced current in a steel wire; the signal processing device is used for extracting and amplifying weak electromagnetic signals and judging the positions and the number of broken wires. By means of internal electromagnetic nondestructive detection, the corrosion and breakage conditions of the prestressed steel wire can be checked in a targeted mode, and thehealth condition of the PCCP pipe is evaluated.

Owner:天津精仪精测科技有限公司

Negative pressure type soft infusion bag

InactiveCN103919679AConvenient and effective exclusionReduce bag leakage rateInfusion devicesPharmaceutical containersMedicineVALVE PORT

The invention discloses a negative pressure type soft infusion bag. According to the manufacturing process steps, material films of inner package bags are sterilized and are merged into a package workshop, the inner package bags are obtained after infusion valves are welded, the inner package bags are filled with liquid medicine, then soft infusion bags are formed, sterilized for the second time and then dried, light inspection is carried out for the first time, unqualified bags with packaging printing errors, welding errors and large impurities are removed, the soft infusion bags are sleeved with outer package bags, negative pressure is pumped between each outer package bag and the corresponding inner package bag, the bags are sterilized for the third time, boxed and placed in a storage to be stored temporarily, then light inspection is carried out for the second time, and leakage bags are removed. By the negative pressure type soft infusion bag, no bacterium can be left in an interlayer, large volume injection with micro-leakage of the inner package bag is conveniently and effectively removed, and the delivery liquid leakage rate is lowered to be below 0.029 per thousand.

Owner:SICHUAN TAIPINGYANG PHARMA

A spark plug for an internal combustion engine and a method thereof

InactiveCN109103749AAvoid affecting the measurement resultsAvoid unexpected situationsSparking plugsEngineeringInternal combustion engine

The invention discloses a spark plug for an internal combustion engine and a method thereof, the spark plug includes a fixed base, the upper end surface of the fixed base is provided with a conveyinggroove with an opening facing upward and extending forward and backward, a conveyor trolley is arranged in the conveyor groove, a fixing groove close to the contour of the spark plug is arranged at the middle position of the upper end face of the conveyor trolley, , an upper end of the left end face of the fixed base is fixedly connected with a main body extending rightward through a fixing block,a lifting space is arranged at the middle position inside the main body, a vertical hydraulic cavity is arranged at the front end of the main body, and the lower end of the hydraulic rod passes through the lower end wall of the hydraulic cavity and is fixedly connected with a detection device. In the work of the invention, the gap between electrodes is measured, the temperature of the spark plugunder the discharge condition is detected when the power supply is energized, the accurate information is obtained through the equipment measurement, the misjudgment caused by manual judgment is avoided, and the qualified rate of the spark plug product is improved.

Owner:惠州秀鸿科技有限公司

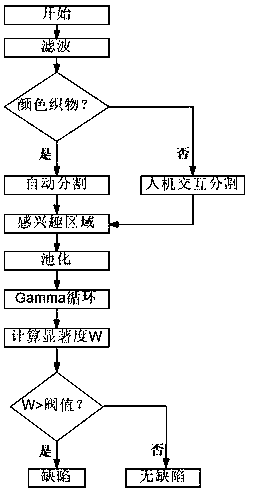

Fabric image defect real-time detection method

PendingCN111062934AWon't interfereRealize unmannedImage enhancementImage analysisEngineeringComputer vision

Owner:陈金选

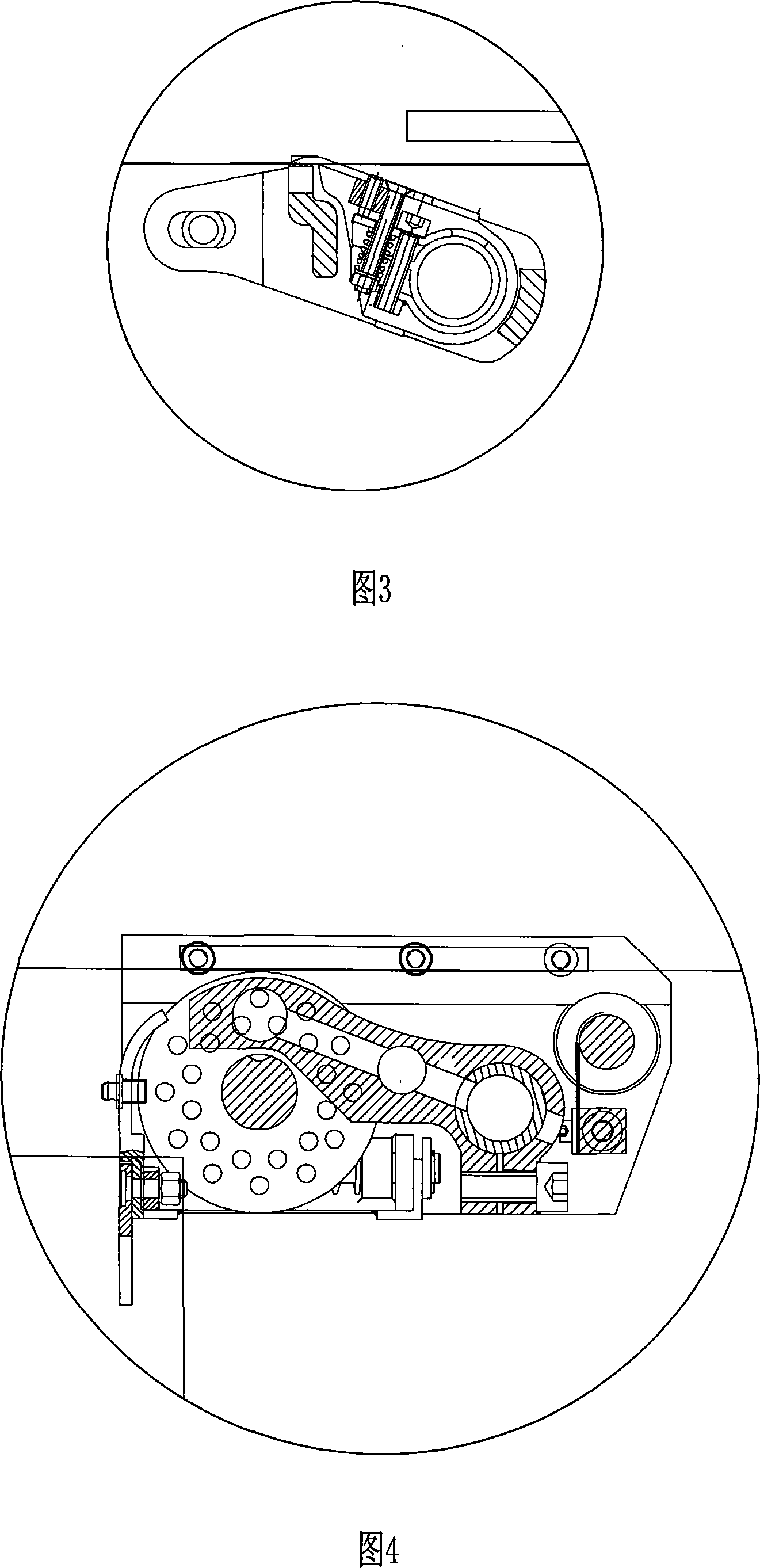

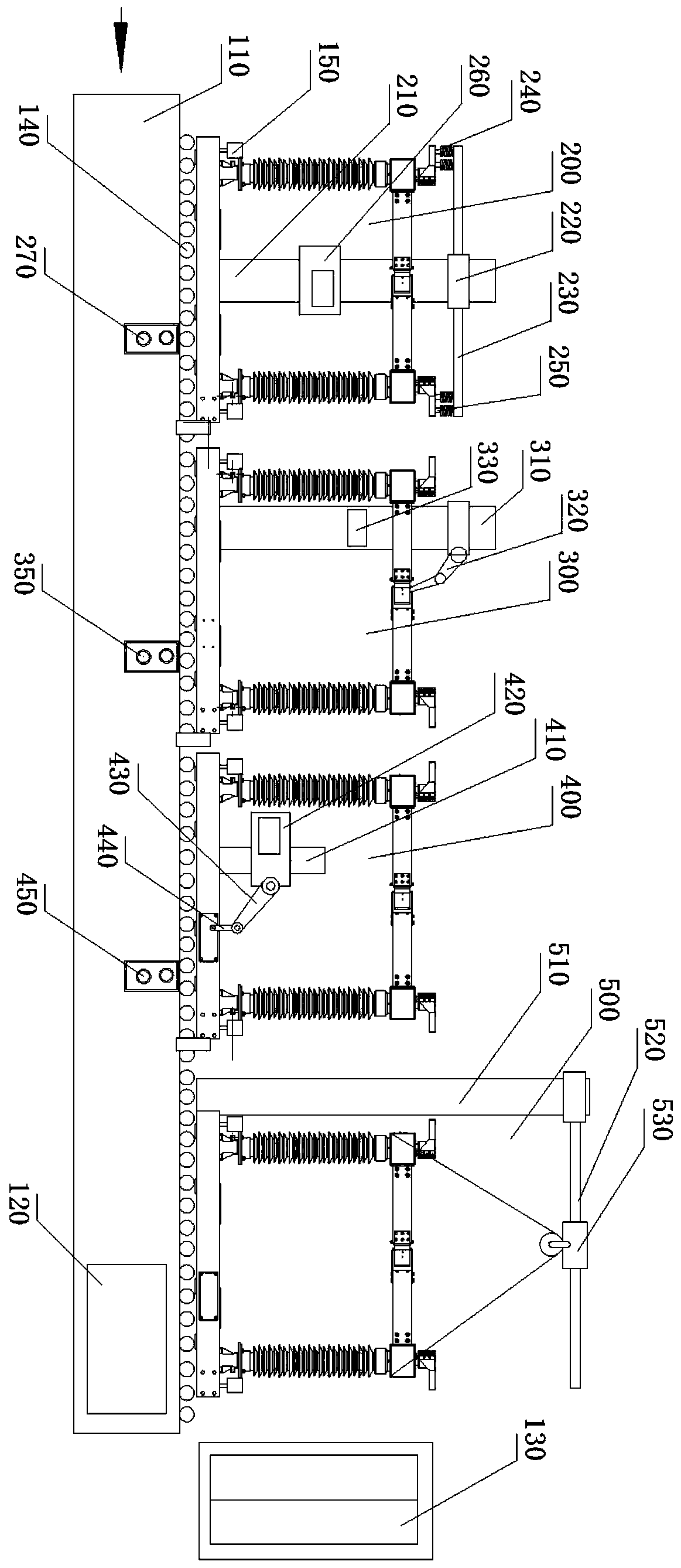

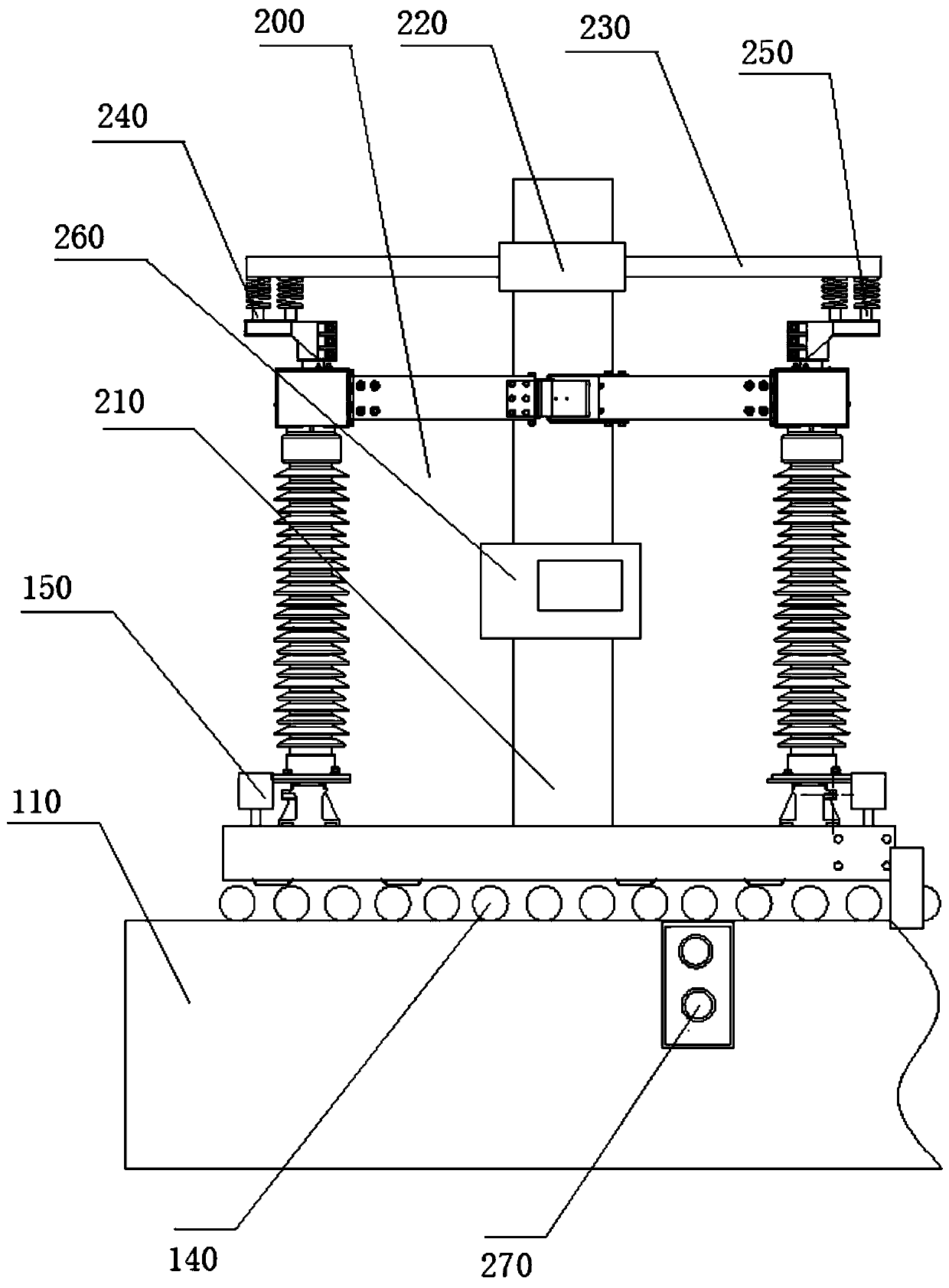

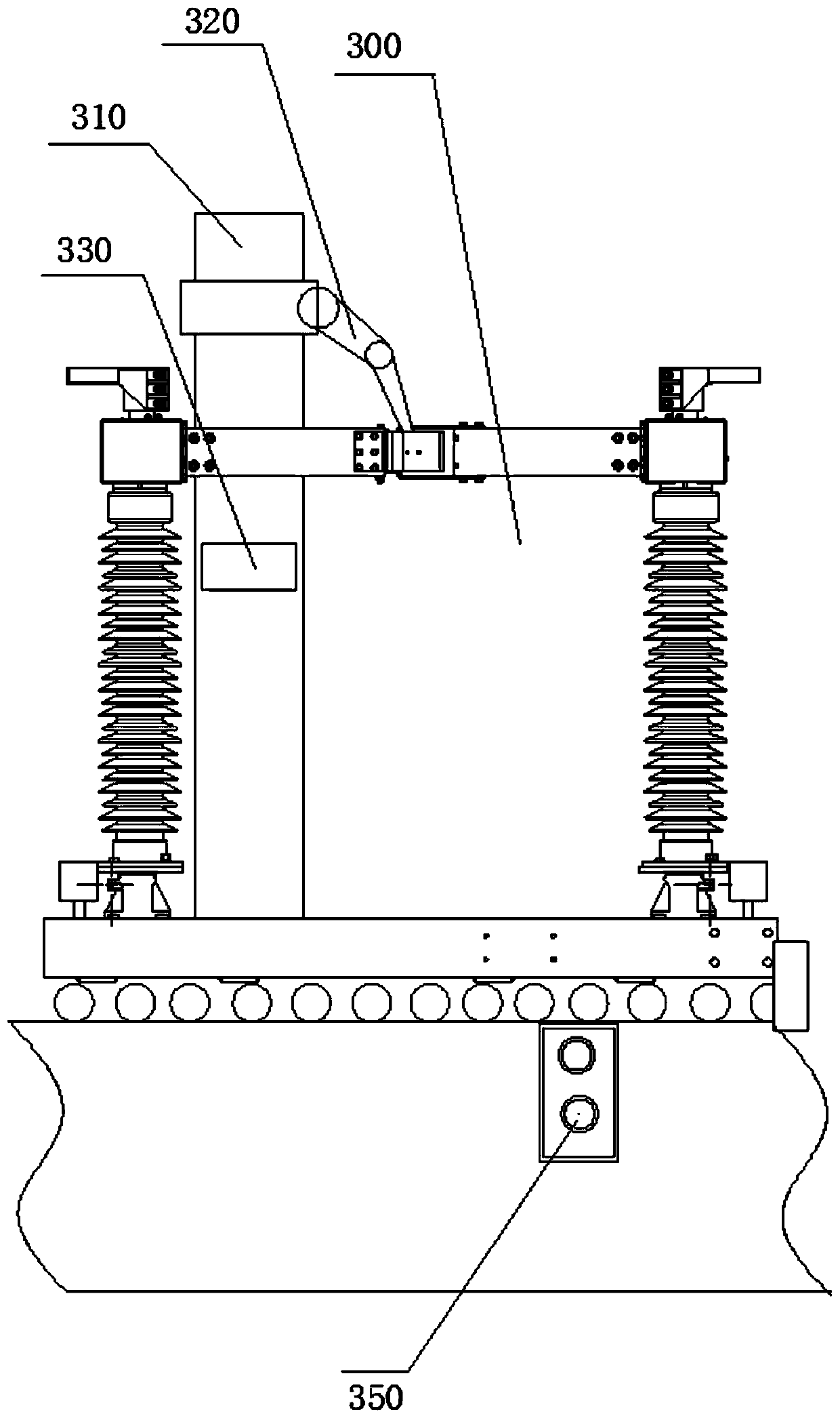

Disconnecting switch delivery inspection assembly line

PendingCN110568353AImprove detection efficiencyLess detectableMachine part testingElectric switchesCommunication interfaceAssembly line

The invention relates to a disconnecting switch delivery inspection assembly line. The disconnecting switch delivery inspection assembly line comprises an assembly line body, a driving unit, an electric control unit, a conveying device, a loop resistance test system, a contact finger clamping force detection system, a nameplate printing system and an offline hoisting system, wherein the loop resistance test system, the contact finger clamping force detection system, the nameplate printing system and the offline hoisting system are sequentially arranged on the assembly line body; and the electric control unit is electrically connected with the driving unit and used for controlling the assembly line to operate through the driving unit. According to the disconnecting switch delivery inspection assembly line provided by the embodiments of the invention, corresponding special detection systems are specially arranged for the important parts of disconnecting switches in an actual use process.Compared with a traditional disconnecting switch detection mode, the special detection systems and an automatic flow detection mode can improve detection efficiency; professional detection systems are adopted, and therefore, human detection errors and errors are reduced, and the ex-factory qualification rate of products is increased; and the disconnecting switch delivery inspection assembly lineis provided with a communication interface, so that product quality can be remotely monitored in real time.

Owner:CHANGGAO ELECTRIC GROUP CO LTD +1

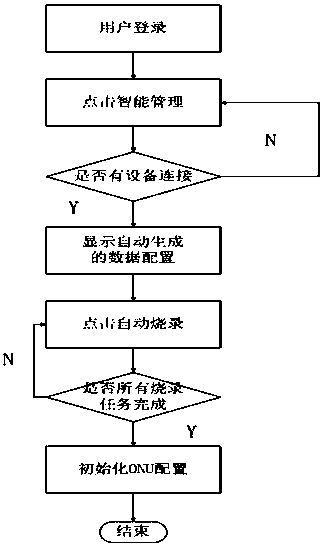

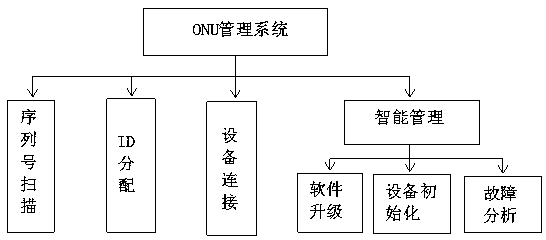

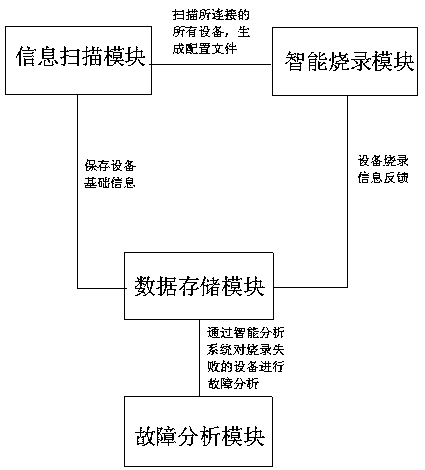

Automatic ONU programming management system

PendingCN108021412AImprove factory pass rateDetection speedProgram loading/initiatingEmbedded systemManagement system

The invention discloses an automatic ONU programming management system. The system comprises an information scanning module, a smart programming module, a data storage module and a fault analysis module; the information scanning module is used for feeding back the acquired ONU equipment information to an interface; the smart programming module is used for programming after ONU equipment is connected, setting a corresponding value to the corresponding ONU equipment through a remote command after the smart programming module reads information contents of the corresponding ONU equipment, and feeding back a programming result to the interface; the data storage module is used for storing the acquired ONU equipment information in the background of the system for later analysis; the fault analysis module is used for intelligently analyzing the status of the acquired ONU equipment to locate the fault and form a fault analysis report. By means of the automatic ONU programming management systemand method, ONU delivery qualification rate is improved, ONU detection speed is accelerated, and manpower cost of inspection lines is saved.

Owner:ZHONGTIAN BROADBAND TECH +1

Round tank inner diameter size rapid detecting machine

ActiveCN111318466AImprove detection efficiencyReduce detection errorMechanical diameter measurementsSortingMechanical engineeringElectrical and Electronics engineering

The invention relates to the inner diameter detection technical field, in particular to a round tank inner diameter size rapid detecting machine. The round tank inner diameter size rapid detecting machine aims at rapidly detecting the round tank inner diameter size, effectively reducing the detection error, and selecting out disqualified products. According to the technical scheme, the round tankinner diameter size rapid detecting machine comprises a mounting frame, a table plate, sliding rails, a first fixed frame, sliding blocks and the like. The table plate is fixedly mounted on one side face of the mounting frame, one side face of the table plate is fixedly provided with the multiple sliding rails, the sliding blocks matched with the sliding rails for fork are slidingly mounted on thesliding rails, a detection wedge block drives extrusion blocks to move downwards to rapidly detect the round tank inner diameter size, the detection efficiency is high, a screw rod is rotated to adjust the position between the two extrusion blocks to carry out standard detection on the size of a round tank, and operation is easy.

Owner:张丽娇

Magnetic sheet inductance automatically detecting machine and implementation method thereof

PendingCN107860983ADetection speedReduce processingResistance/reactance/impedenceWebs handlingSheet filmMachine

The invention discloses a magnetic sheet inductance automatically detecting machine. The magnetic sheet inductance automatically detecting machine comprises a marking mechanism, a feeding driving mechanism, a position detecting platform, a feeding mechanism, a position detecting sensor, an inductance testing mechanism and a machine frame, wherein the inside of the machine frame is provided with anelectric control cabinet, and the top side edge of the machine frame is provided with the feeding mechanism. The invention also discloses an implementation method of the magnetic sheet inductance automatically detecting machine. Through a set of complete detecting line, filmed magnetic sheet film tapes can be placed inside a detecting table for detection, so that a large amount of time can be saved, and the detecting speed of the magnetic sheet film tapes can be greatly increased; the magnetic sheet inductance automatically detecting machine is fully automated, so that an operator only needsto place the magnetic sheet film tapes into the detecting table, the detecting table can detect the magnetic sheet film tapes according to a set program, so that the automation degree can be greatly improve, the labor intensity of detecting personnel can be reduced, and compared original manual detection, the detecting speed and the detecting quality can be improved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Assembling method for crank-connecting rod assembly

InactiveCN105058019ADisplay the specific data of the press loadEasy to operateMetal working apparatusPass rateEngineering

The invention discloses an assembling method for a crank-connecting rod assembly. According to the method, an oil press, a pressure head, an upper mould and a lower mould are included, wherein the upper mould and the lower mould are fixedly installed on the oil press, the upper mould is used for positioning a left crank and the lower mould is used for positioning a right crank; the pressure head is provided with a load sensor, and a linear displacement sensor is connected with and installed on the pressure head; two positioning rods capable of sliding in the axial direction are arranged at the positions, corresponding to pin holes of the cranks, of the upper mould and the lower mould respectively in the axial direction; the end, away from the corresponding pin hole, of each positioning rod is provided with a position sensor; the distance between the position sensors and the end face where a crank pin is designed and installed is equal to the length of the positioning rods when the moulds are combined. The assembling method has the advantages that operation is convenient, press-fitting loads generated when the two ends of the crank pin are installed in place can be detected, and the ex factory pass rate can be increased.

Owner:重庆建设·雅马哈摩托车有限公司

Forging method and forging device of twice forcing molten soup forging wheel

ActiveCN103084559BAvoid damageMeet the mechanical performance requirementsEngineeringMechanical engineering

The invention relates to a forging method and a forging device of a twice forcing molten forging wheel. The forging method of the twice forcing molten forging wheel is conducted circularly by the following steps: (1) materials smelting; (2) heat preservation deposit; (3) molten soup degassing; (4) the molten soup being injected into a lower die; (5) main piston forcing and pressure maintaining; (6) auxiliary piston forcing and pressure maintaining; (7) die sinking; (8) product transfer and deposit; (9) die cooling. Product quality is improved and molten soup dosage is reduced, and twice forcing is conducted to further improve inner structure refined grain of metals, and therefore the forging method and the forging device of the twice forcing molten forging wheel has the advantages of improving product mechanical property, tensile property and other overall properties, shortening product production time, increasing output, improving production efficiency and ex-factory percent of pass of products.

Owner:TIANJIN NANUO MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com