Glass foreign bubble detecting method

A detection method and glass technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of low reliability, foreign objects or bubbles in the glass, etc., and achieve the goal of improving reliability and increasing the pass rate of the factory Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

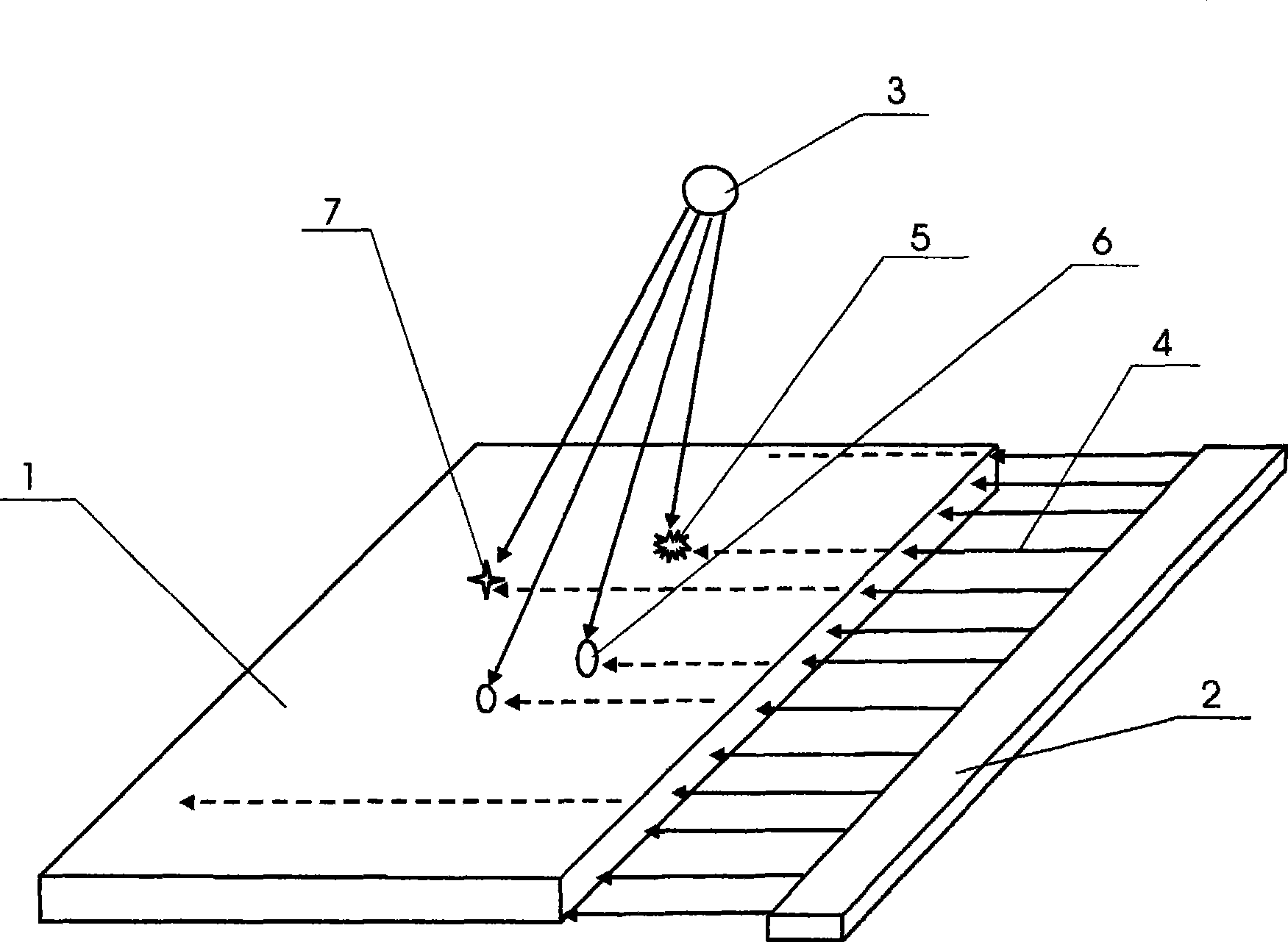

[0010] The first step is to lay the glass to be inspected (1) horizontally, and after placing it stably, set the laser light source (2) on the right side of the glass to be inspected (1), and set the computer linear scanning head (3) on the glass to be inspected (1) above.

[0011] The second step is to turn on the laser light source (2), the laser line (4) is transmitted into the glass (1) to be inspected from the right side of the glass (1) to be inspected at a positive transmission angle, and the computer linear scanning head (3) scans the transmission Enter the laser line (4) in the glass (1) to be inspected, and at the same time, transmit the scanning result to the computer for processing, and judge whether the transmitted laser line (4) is blocked or change the transmission direction, etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com