Magnetic sheet inductance automatically detecting machine and implementation method thereof

A detection machine and inductance technology, applied in the direction of measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of low automation, low detection efficiency and high error rate, so as to improve detection speed and reduce Processing and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

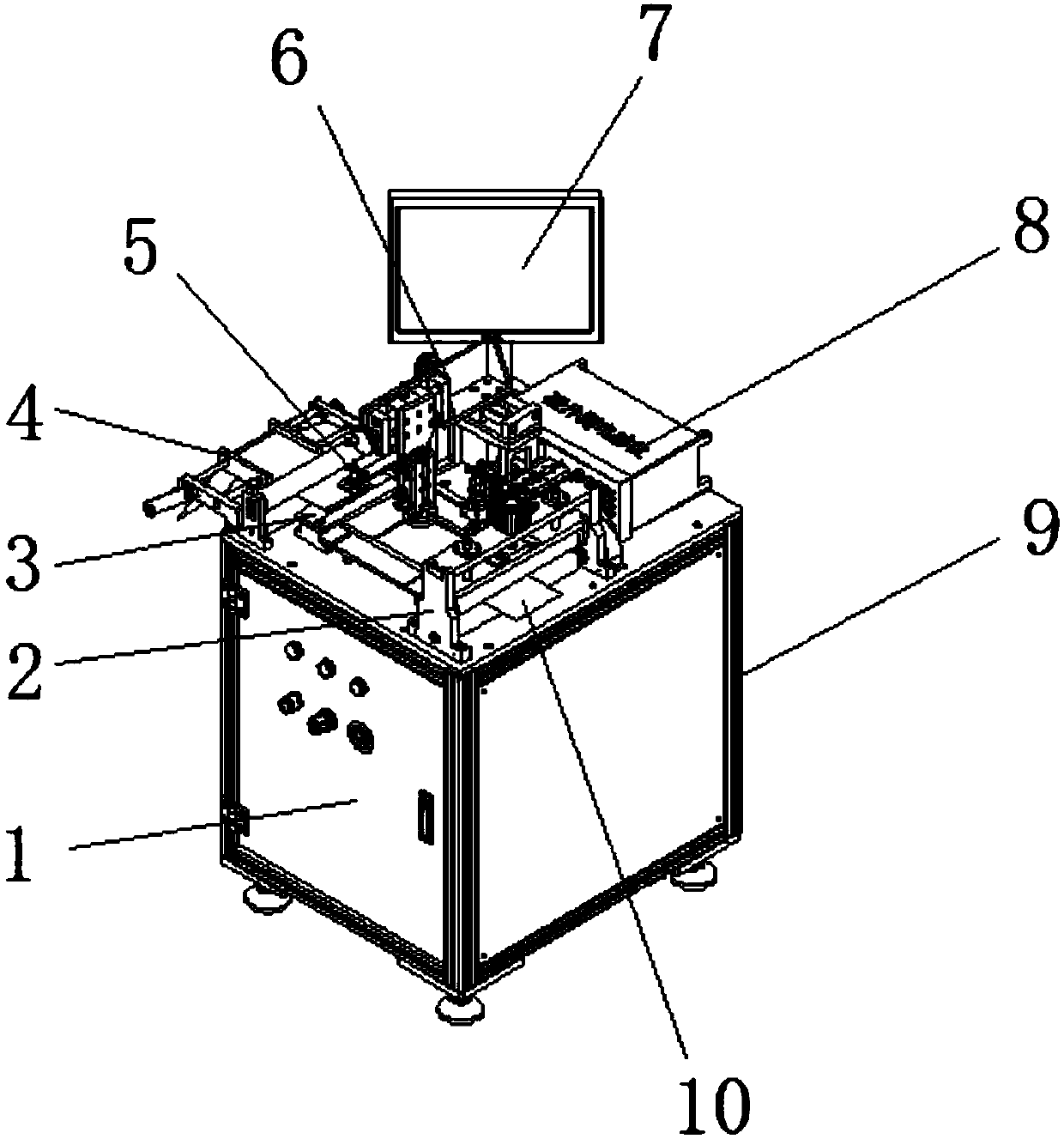

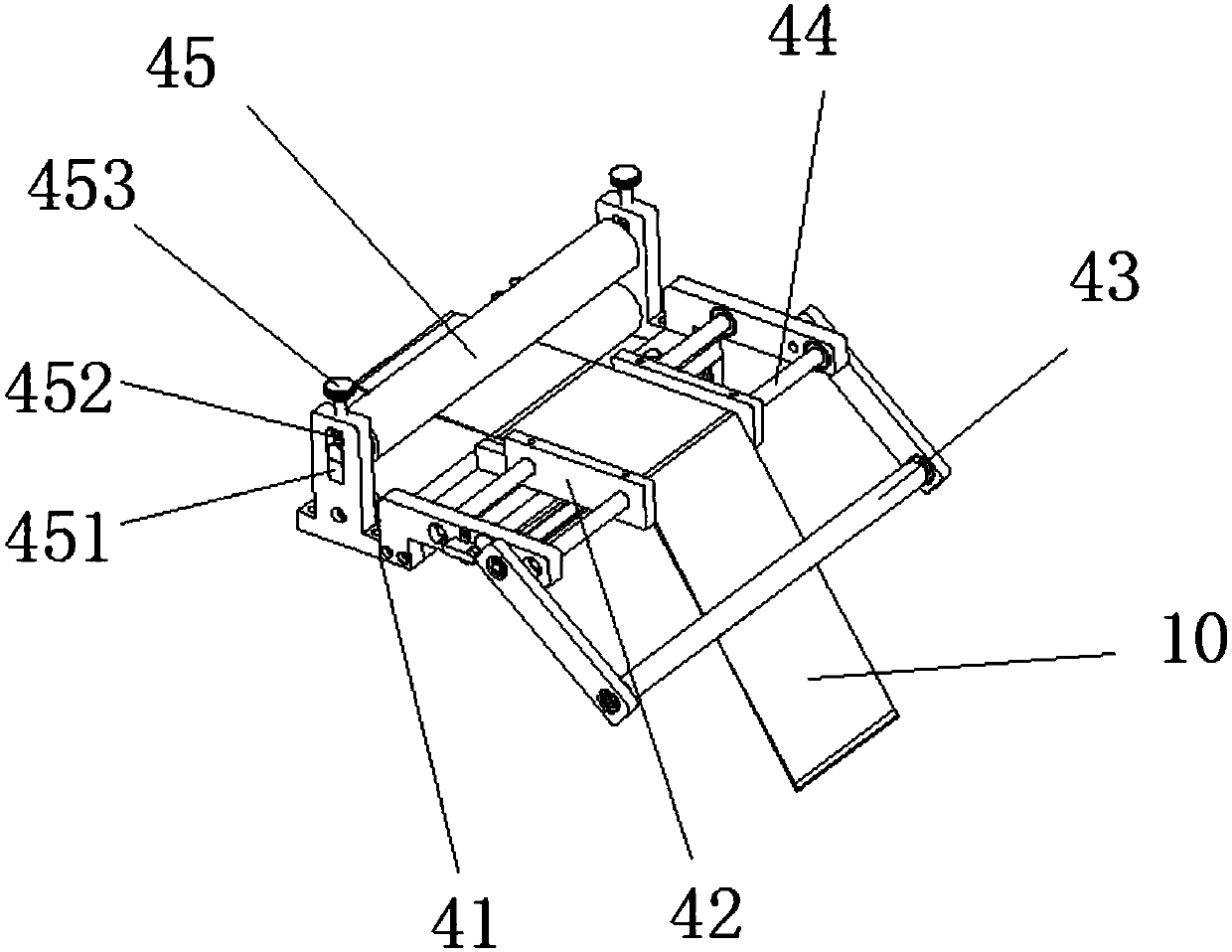

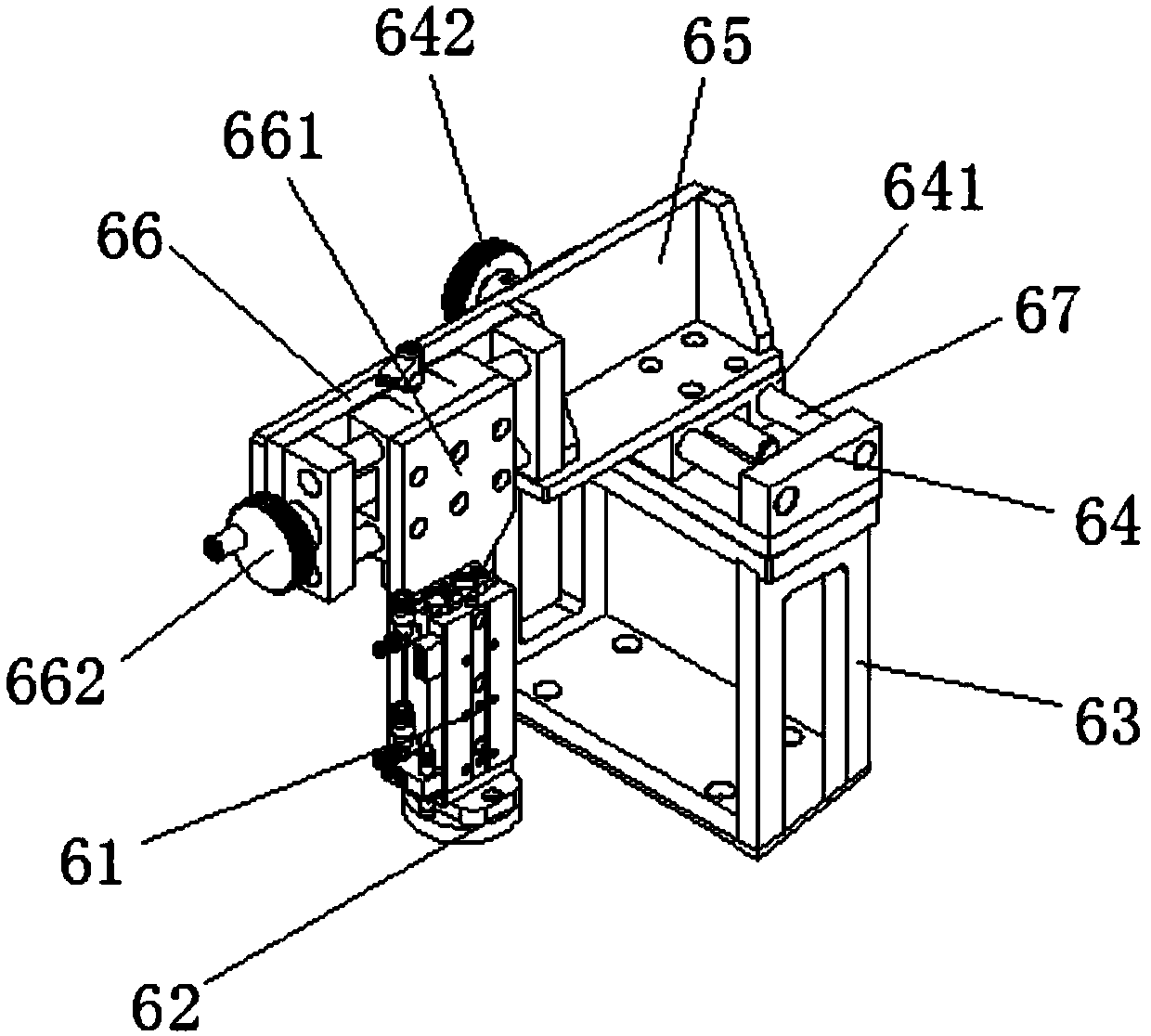

[0032] see Figure 1-4 , the present invention provides the following technical solutions: an automatic detection machine suitable for magnetic sheet inductance, including a marking mechanism and a feeding drive mechanism 2, a position detection platform 3, a feeding mechanism 4, a position detection sensor 5, and an inductance testing mechanism 6 , frame 9; wherein, the inside of frame 9 is provided with electric control box 1, and the side above frame 9 is provided with feeding mechanism 4, and one side of feeding mechanism 4 is provided with position detection platform 3, and position detection The platform 3 is fixedly installed on the top of the frame 9 by fastening bolts, the position detection sensor 5 is arranged on the side near the feeding mechanism 4 above the position detection platform 3, and the position detection sensor 5 is connected with the position detection platform 3 through a bracket, and the position The side of the detection platform 3 away from the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com