Disconnecting switch delivery inspection assembly line

A technology for isolating switches and ex-factory inspection, which is applied in the testing of electric switches, circuit breakers, and mechanical components. It can solve problems such as difficult to achieve production efficiency, difficult to control the quality of inspection, and incompatibility, so as to reduce manual inspection. Mistakes and errors, real-time remote monitoring of product quality, and the effect of improving the factory pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

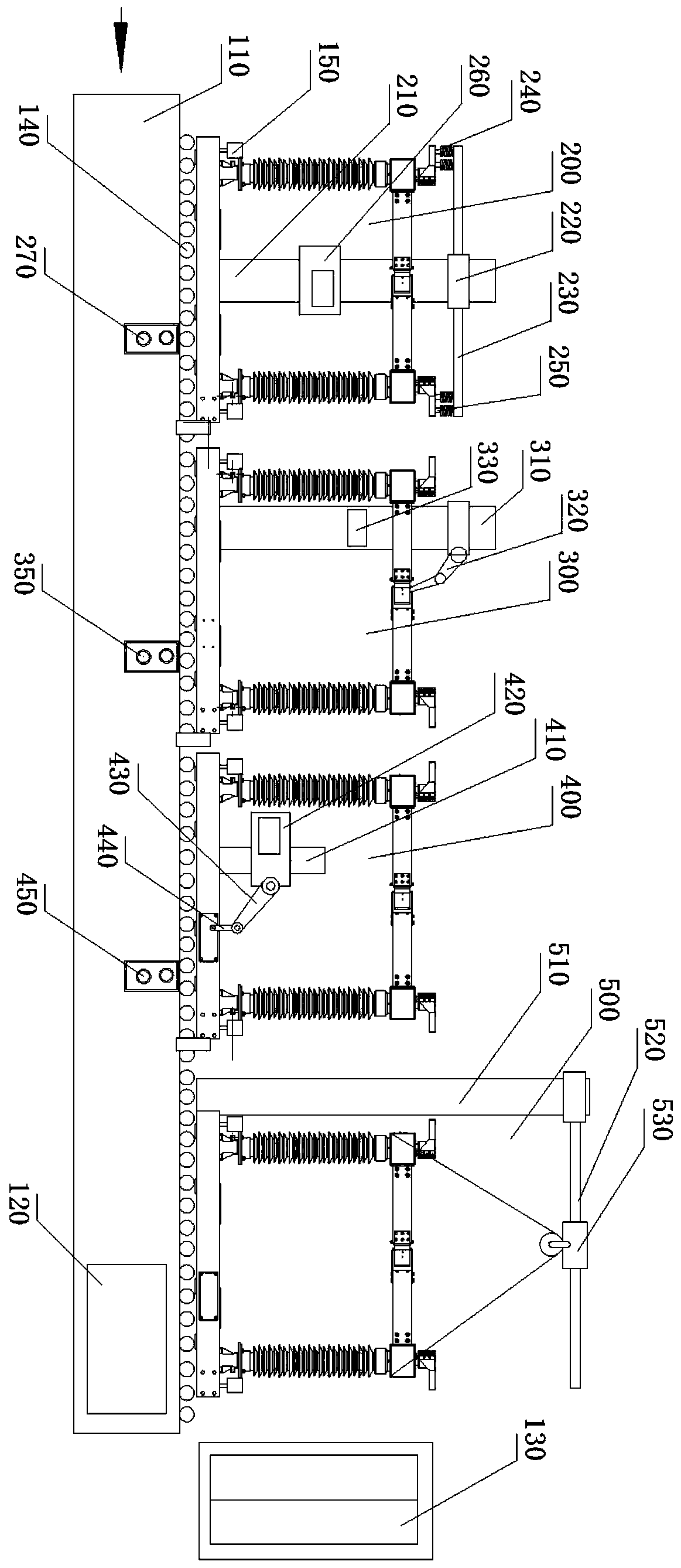

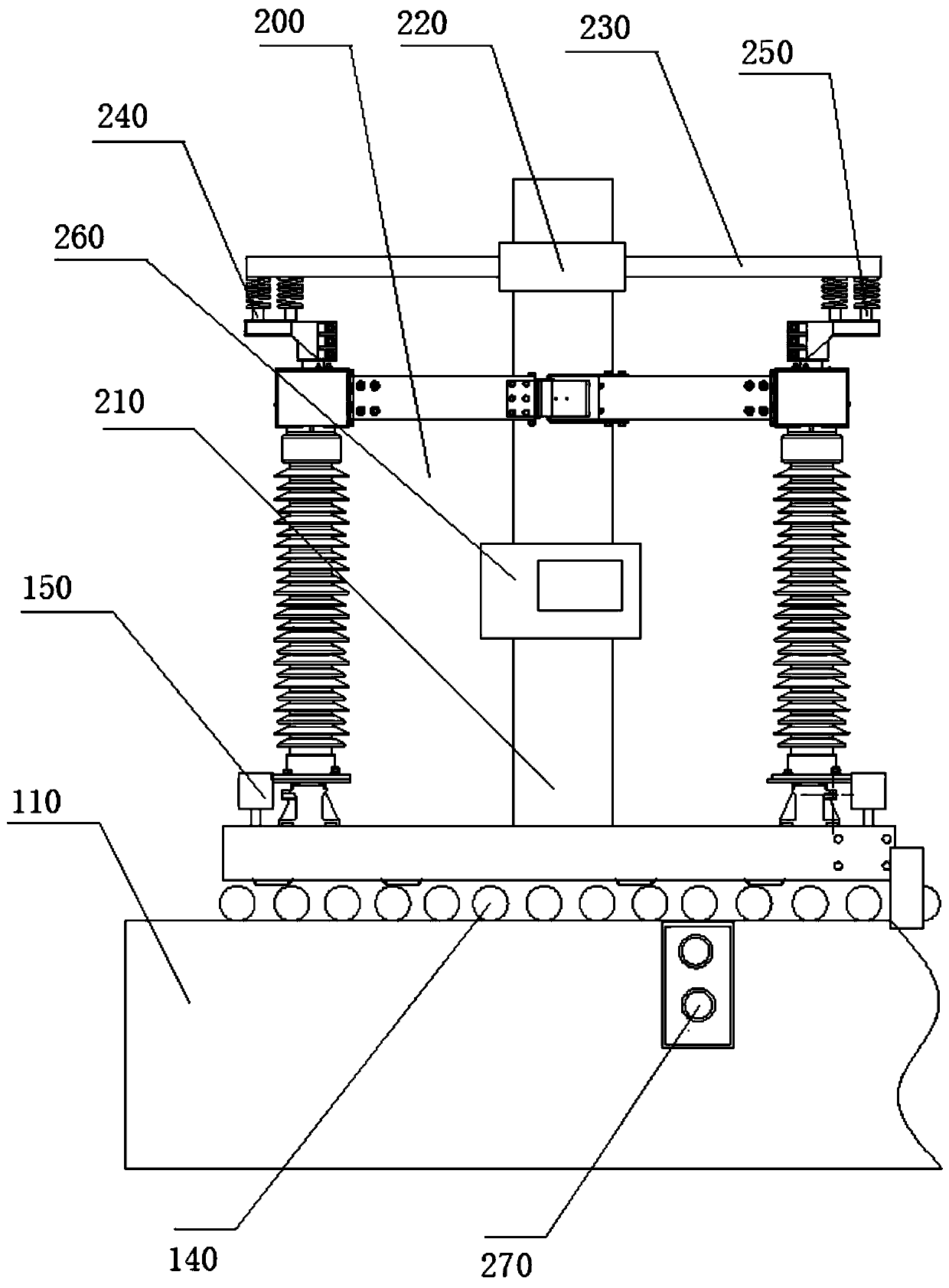

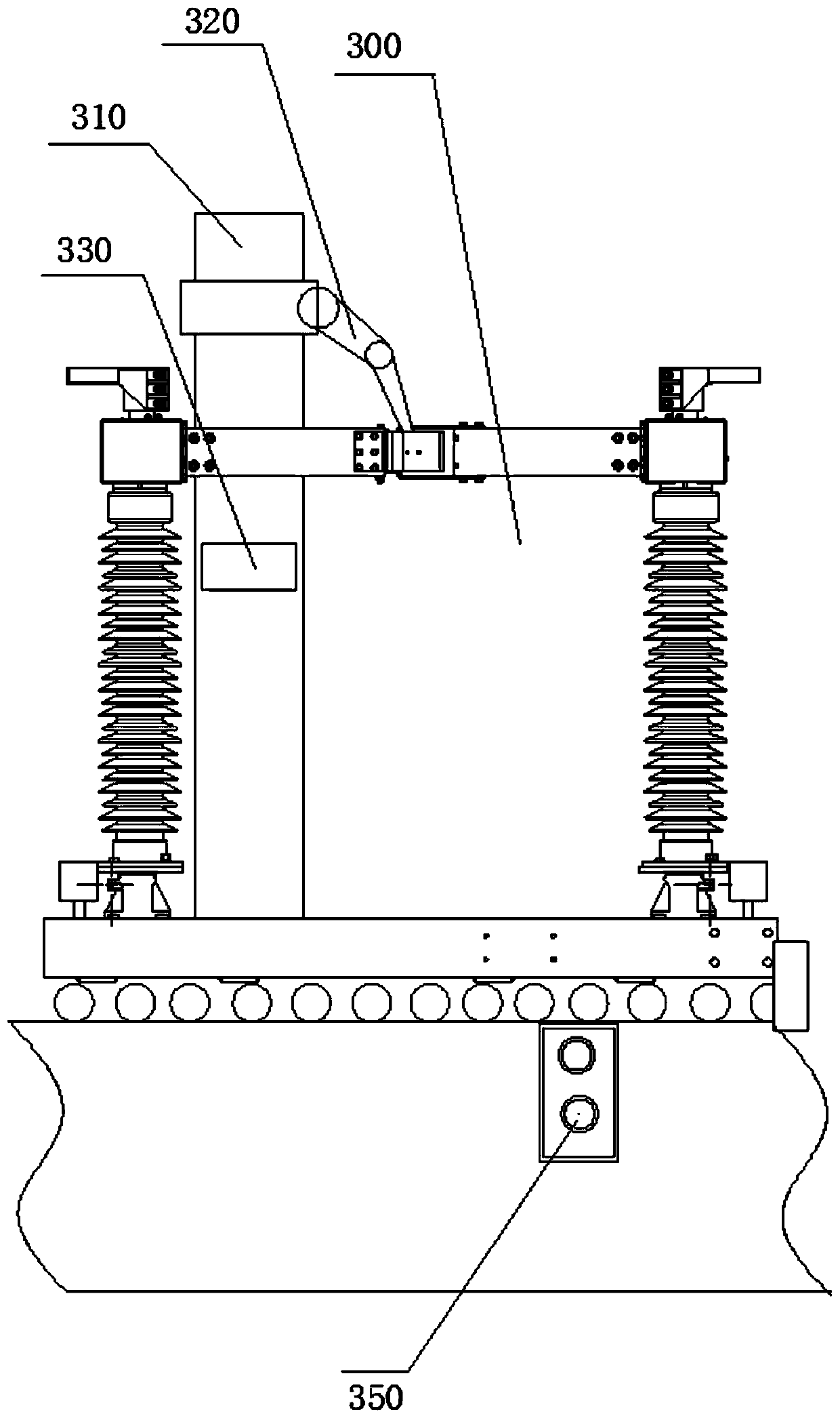

[0028] Such as figure 1 As shown, a factory inspection assembly line for isolating switches includes an assembly line body 110, a drive unit 120, an electronic control unit 130, a transmission device 140, and a circuit resistance testing system 200 and a finger clamping force detection system sequentially arranged on the assembly line body 110. 300, nameplate printing system 400, off-line hoisting system 500;

[0029] The transfer device 140 is arranged on one side of the top of the pipeline body 110, and is used to transfer the isolating switch from one system to the next system;

[0030] The electronic control unit 130 is electrically connected with the drive unit 120, and is used to control the operation of the assembly line through the drive unit 120; the transmission device 140, the loop resistance test system 200, the finger clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com