Round tank inner diameter size rapid detecting machine

A detection machine and inner diameter technology, applied in the direction of mechanical diameter measurement, sorting, etc., can solve the problems that affect the pass rate of round cans and the shortcomings of later use, large detection errors in the inner diameter of round cans, and the selection of defective products, etc., to achieve Easy to operate, improve the pass rate of the factory, and reduce the effect of detection error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

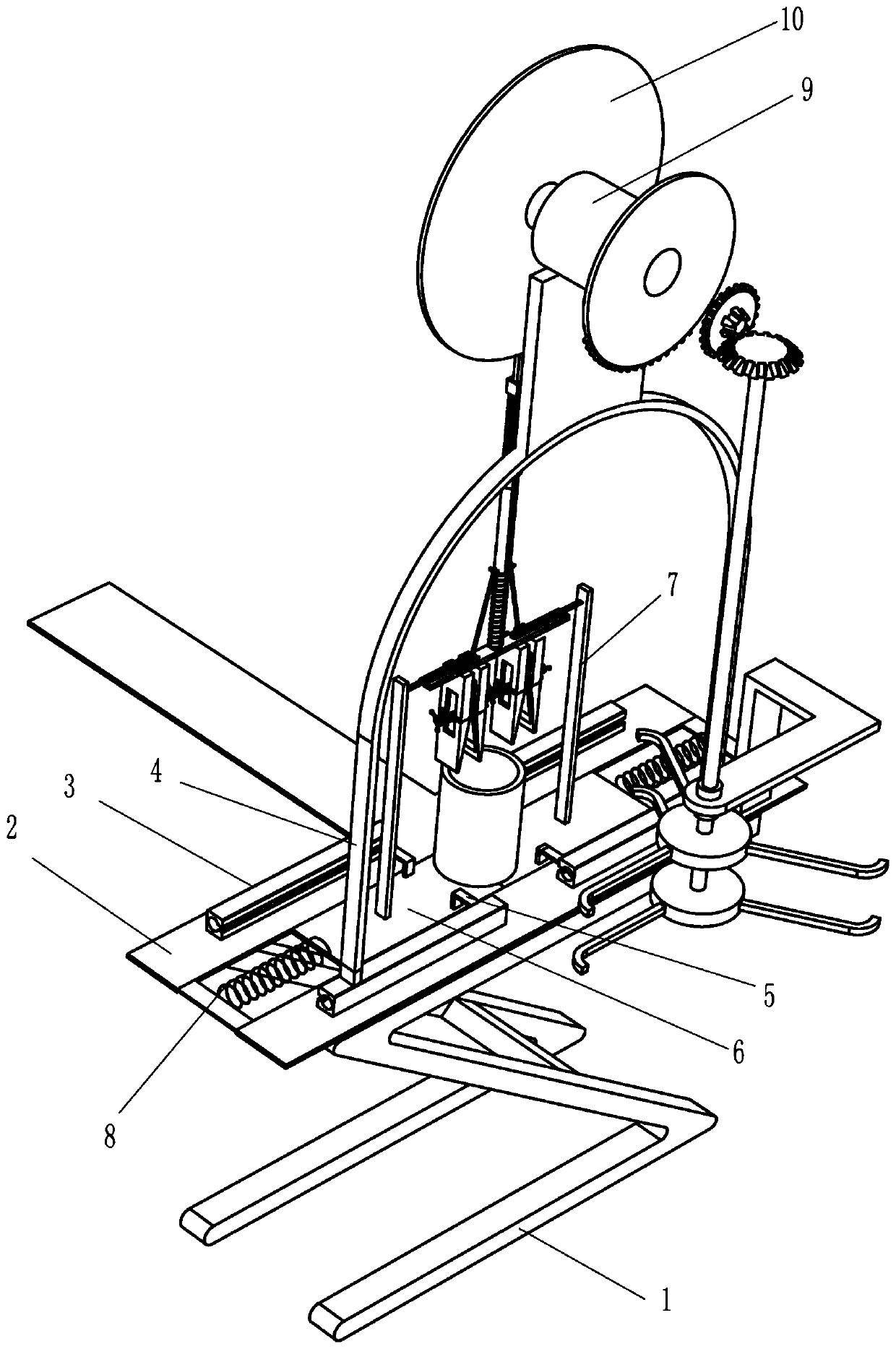

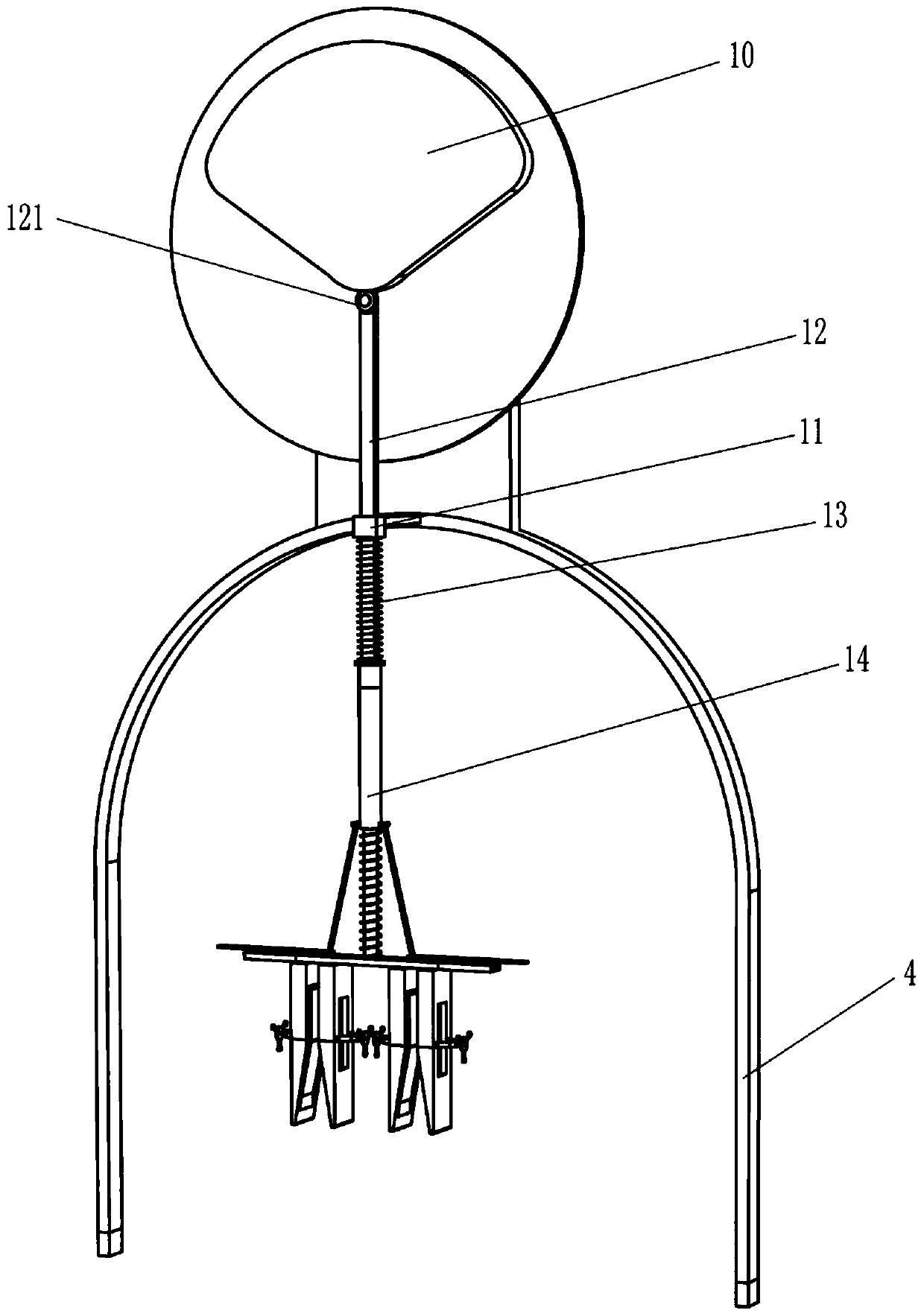

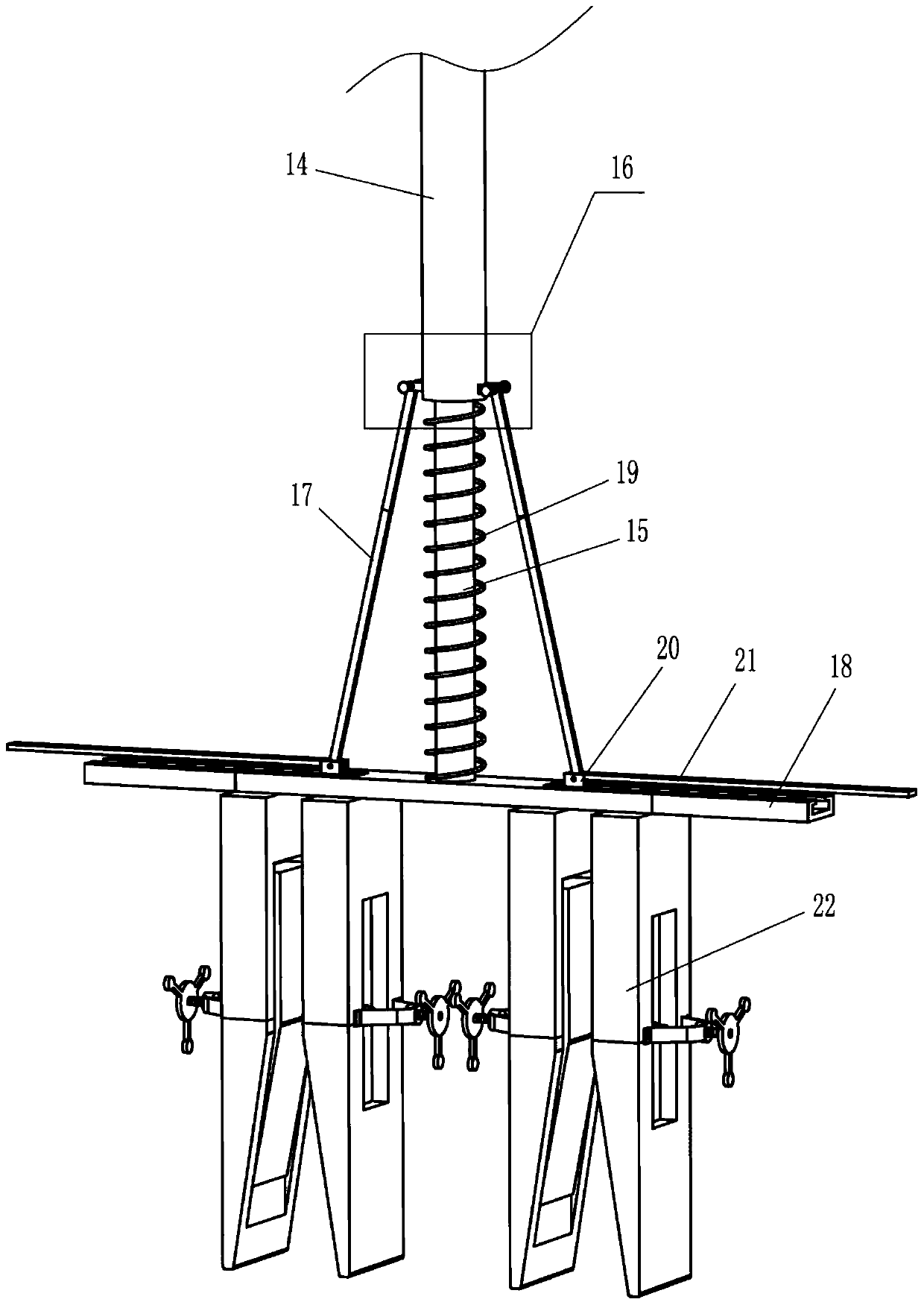

[0023] A rapid detection machine for the inner diameter of round cans, such as Figure 1-7 As shown, it includes a mounting frame 1, a table plate 2, a slide rail 3, a first fixed frame 4, a slider 5, a sliding support plate 6, a push plate 7, a homing elastic member 8, a bidirectional motor 9, and a squeeze plate 10 , Square guide sleeve 11, Square guide rod 12, Roller 121, Resetting elastic member 13, Hollow sleeve 14, Sliding cylinder 15, Reset device 16, Swing rod 17, Movable guide rod 18, Extrusion elastic member 19, Guide block 20 , a push rod 21 and a detection wedge 22, the table board 2 is fixedly installed on the upper side of the mounting frame 1 and the middle part of the table board 2 is hollow, and the upper side of the table board 2 is fixed along the horizontal direction. Slide rail 3, the slide block 5 that cooperates with it is all slidably installed on the 4 slide rails 3, and the first fixed frame 4 is fixedly installed on the upper side of two slide rails ...

Embodiment 2

[0028] A rapid detection machine for the inner diameter of round cans, such as Figure 1-7 As shown, it includes a mounting frame 1, a table plate 2, a slide rail 3, a first fixed frame 4, a slider 5, a sliding support plate 6, a push plate 7, a homing elastic member 8, a bidirectional motor 9, and a squeeze plate 10 , Square guide sleeve 11, Square guide rod 12, Roller 121, Resetting elastic member 13, Hollow sleeve 14, Sliding cylinder 15, Reset device 16, Swing rod 17, Movable guide rod 18, Extrusion elastic member 19, Guide block 20 , a push rod 21 and a detection wedge 22, the table board 2 is fixedly installed on the upper side of the mounting frame 1 and the middle part of the table board 2 is hollow, and the upper side of the table board 2 is fixedly installed with four slide rails 3 , the four slide rails 3 are all slidably installed with sliders 5 cooperating with them, the first fixed frame 4 is fixedly installed on the upper side of two of the slide rails 3, the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com