Fabric image defect real-time detection method

A real-time detection and fabric technology, applied in image enhancement, image analysis, image data processing, etc., can solve the problems of not having too much difference, false detection, and image algorithm is difficult to apply to industrial practice, so as to improve the pass rate of the factory Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

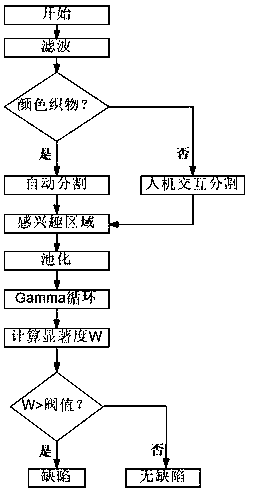

[0027] Example: such as figure 1 As shown, the image acquired by an industrial camera is first processed by median filtering (median filtering refers to the operation of taking the mean value of the neighboring pixels of a pixel point to replace the pixel value of the point, and median filtering can remove the noise point of the image), and then Separate the three channels of the filtered fabric image R, G, and B, generate 3 color feature images and calculate the mean value of all pixel values of each image, and subtract the maximum mean value from the minimum mean value to obtain the maximum difference mean value, if the maximum difference If the average value is greater than the preset difference threshold, it is judged as a colored fabric, otherwise it is judged as a non-colored fabric.

[0028] If it is judged as a color fabric, subtract the color feature map corresponding to the minimum mean value from the color feature map corresponding to the maximum mean value to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com