Quality detecting device for bottle body plug adding

A detection device and bottle body technology, which is applied in the direction of optical testing for flaws/defects, etc., can solve the problems of lower qualified rate of finished products, pressure deviation, and untightened rubber stoppers, etc., to improve the qualified rate of the factory, high detection accuracy, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

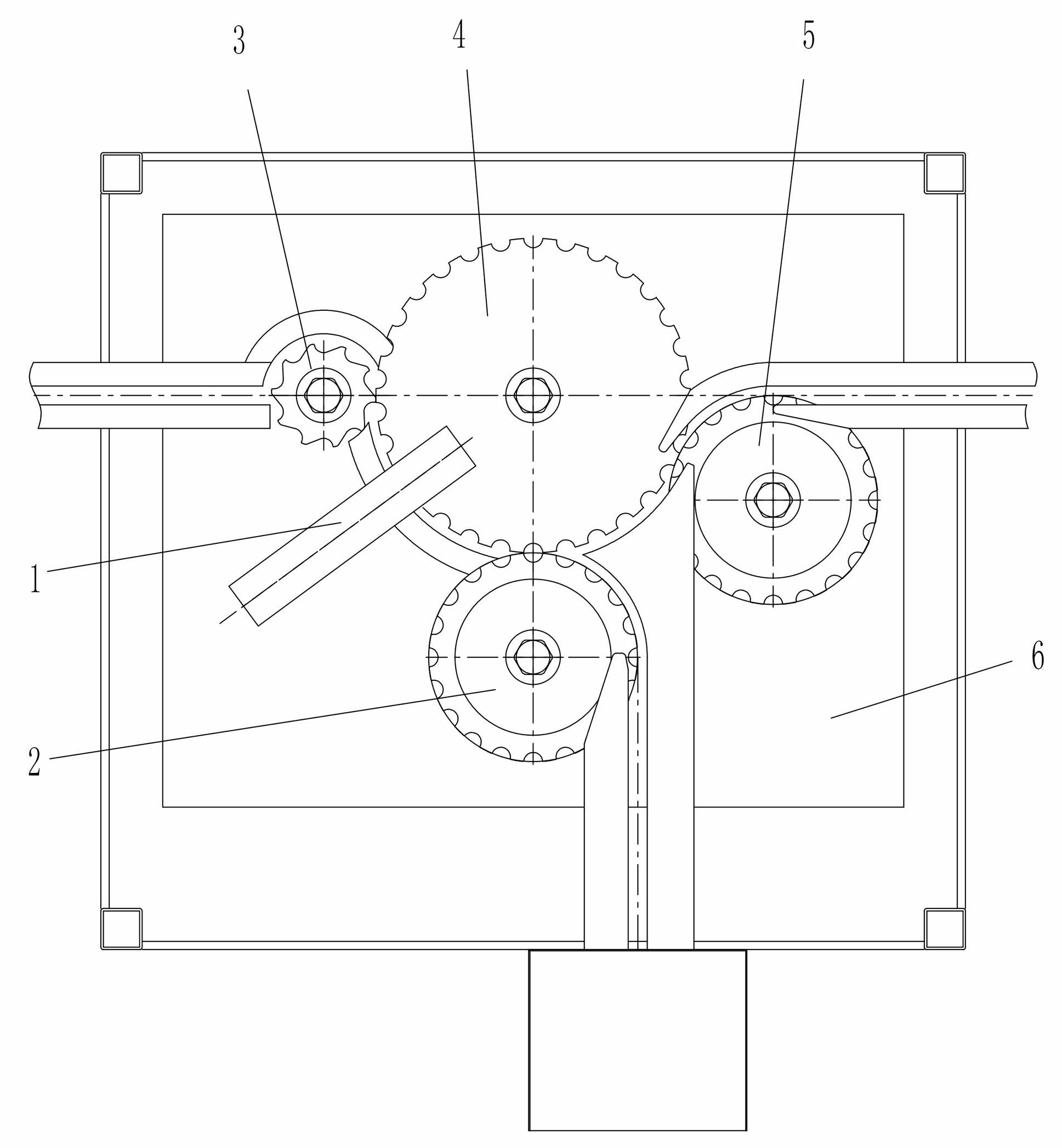

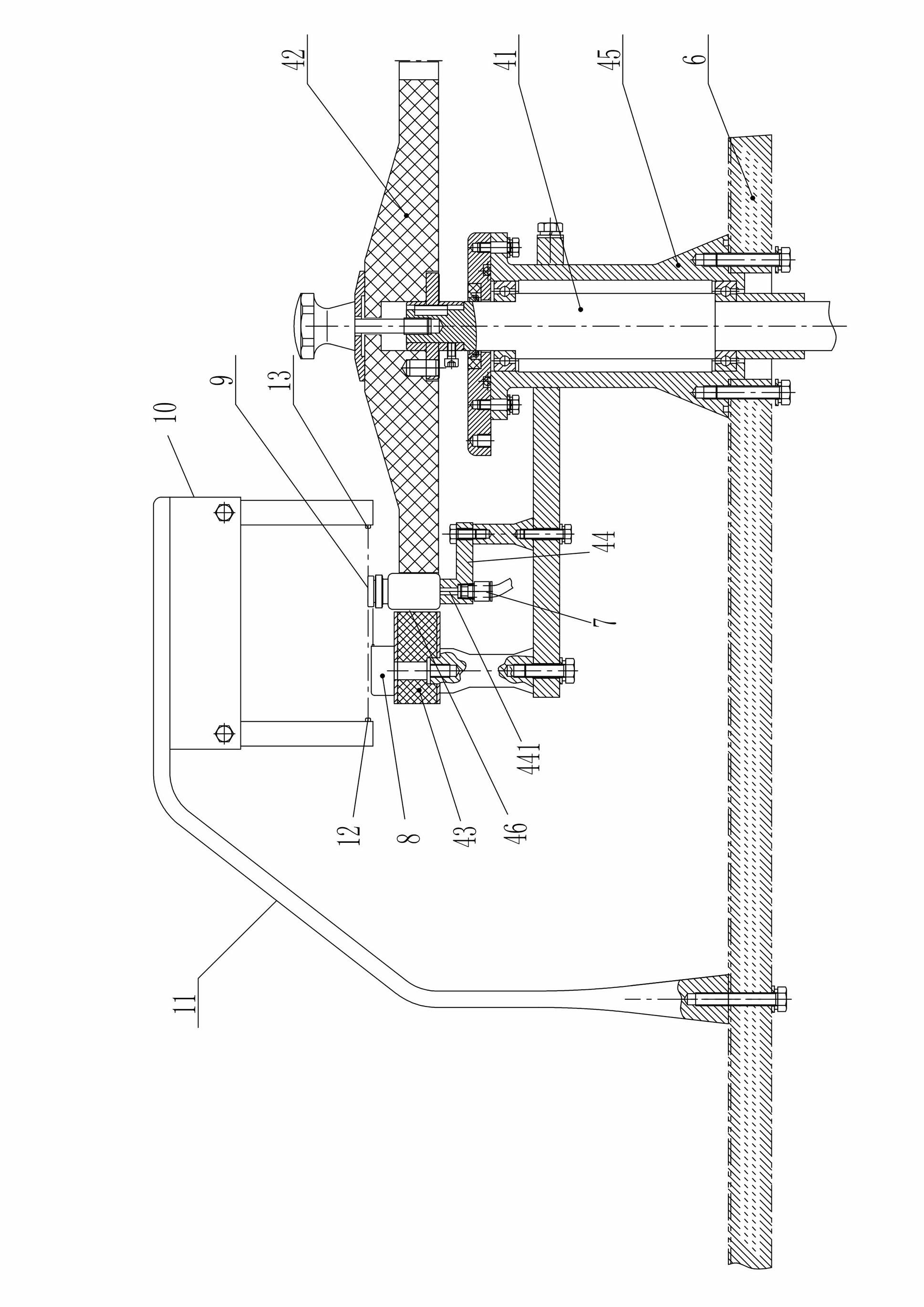

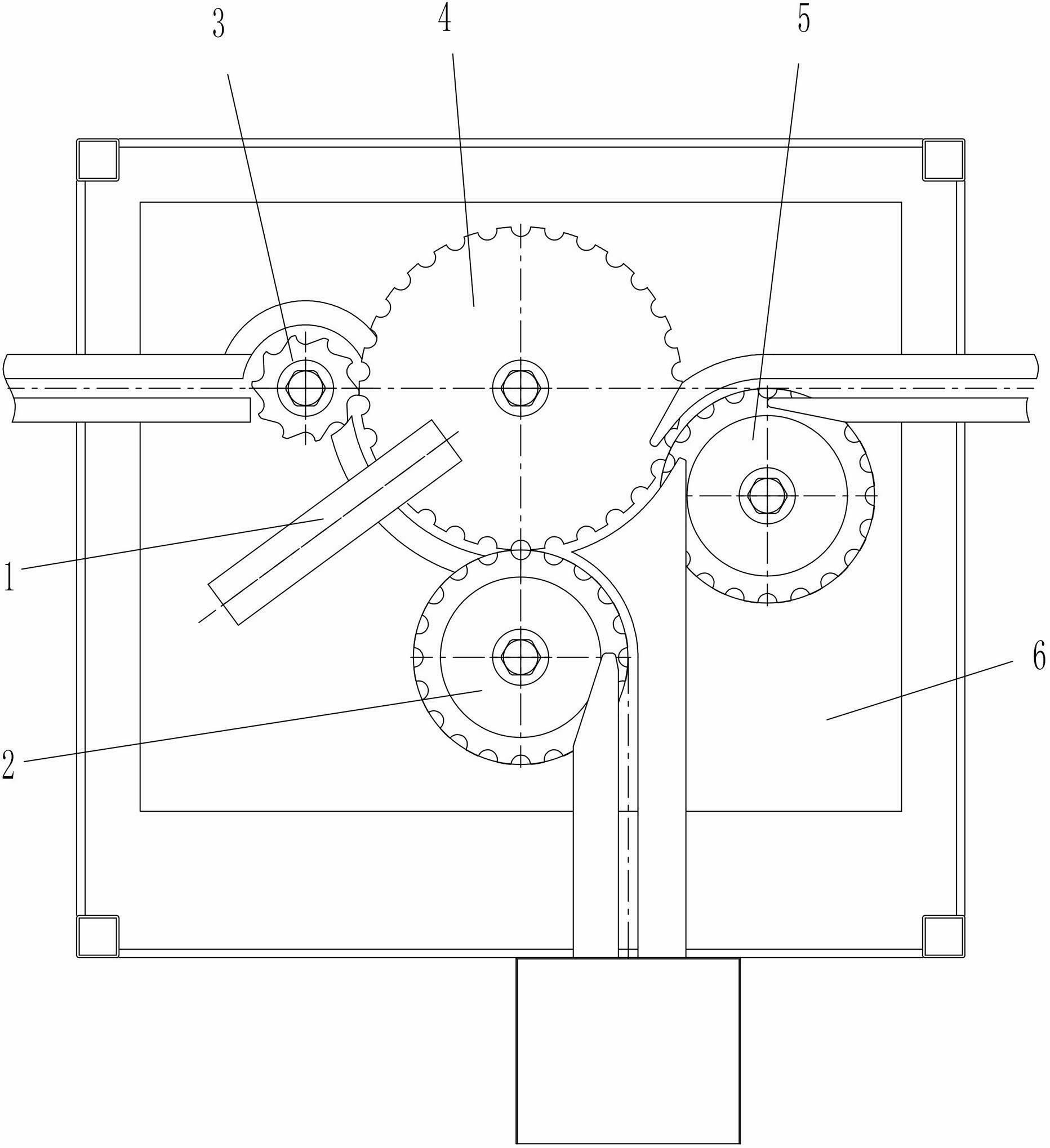

[0021] Such as figure 1 , figure 2 As shown, the bottle stoppering quality detection device of the present invention includes a first detection component 1, a rejecting component 2 and a bottle conveying component 4, and the first detecting component 1 and the rejecting component 2 are sent along the bottle conveying component 4. The bottle direction is arranged sequentially. The first detection component 1 includes a light source transmitter 12 and a light source receiver 13 , and the light source transmitter 12 is arranged opposite to the light source receiver 13 on both sides of the bottle to be detected on the bottle delivery component 4 . By properly setting the level of the light source emitter 12 and the light source receiver 13, the signal light of the light source emitter 12 can just pass through the top of the bottle rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com