Automatic test system and method

An automatic test system and automatic test technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of heavy workload, low manual operation efficiency, error-prone, etc. The effect of improving the factory pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

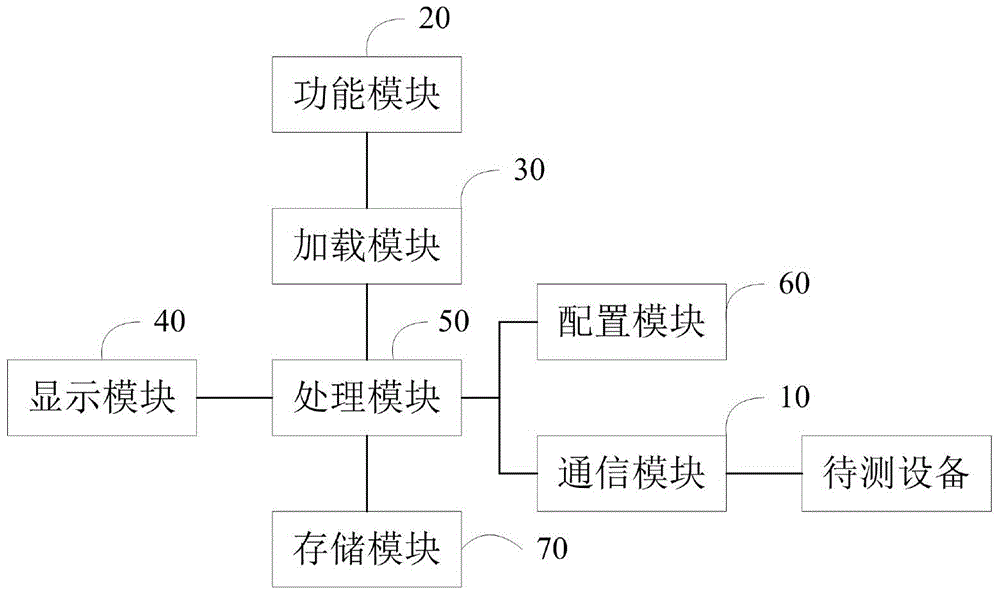

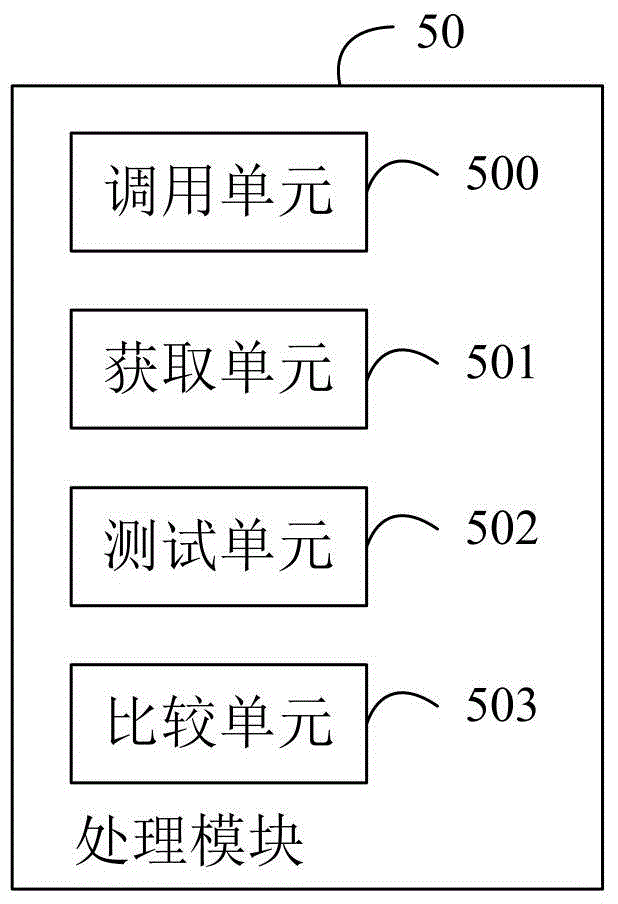

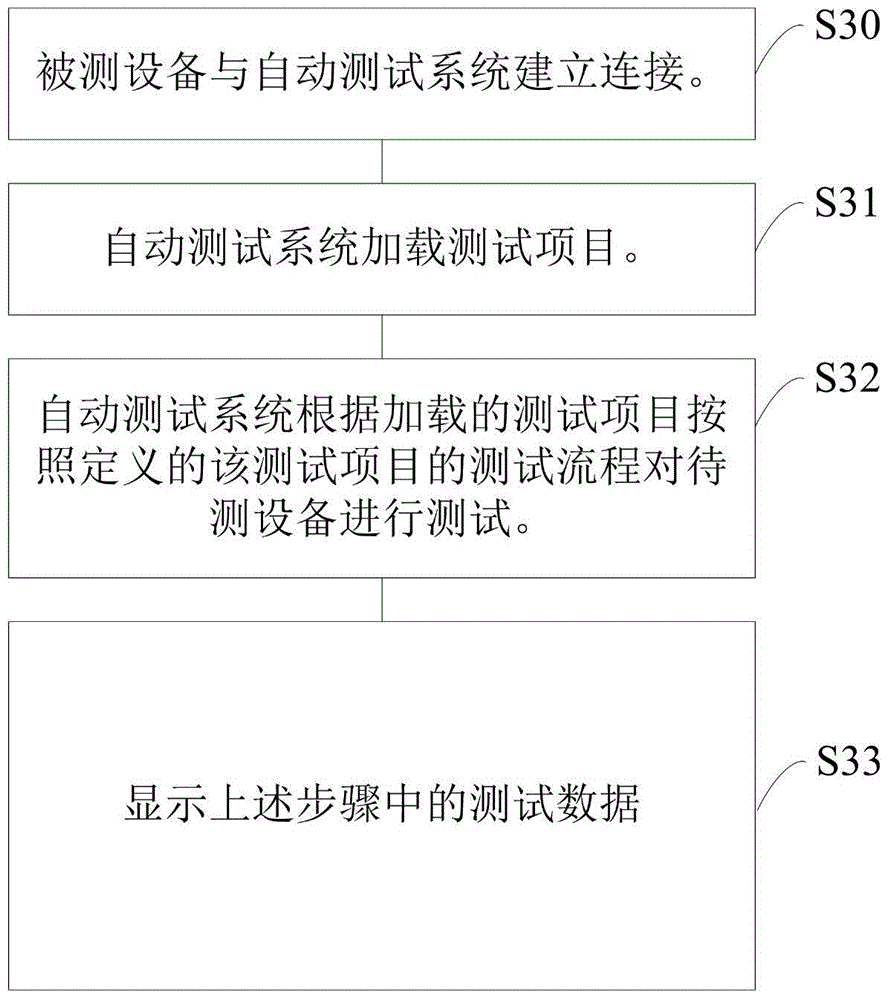

[0020] Such as figure 1 Shown is a schematic structural diagram of an automatic test system in a preferred embodiment of the present invention, and the automatic test system includes: a communication module 10, which is used to connect with the device under test to perform data communication with the device under test, mainly including a serial port communication module and / or Or WIFI wireless communication module and / or Ethernet communication module. The function module 20 is used to define the test items of the device under test and the corresponding test process. Specifically, the test items are defined according to the functions of the device under test, and the test process is defined according to the business element flow of the test item. The device under test can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com