Gearbox test bed

A test bench and gearbox technology, applied in the field of gearbox testing, can solve the problems of reducing the testing effect, large noise, affecting product quality, etc., to achieve the effect of controlling product quality and improving the pass rate of the factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

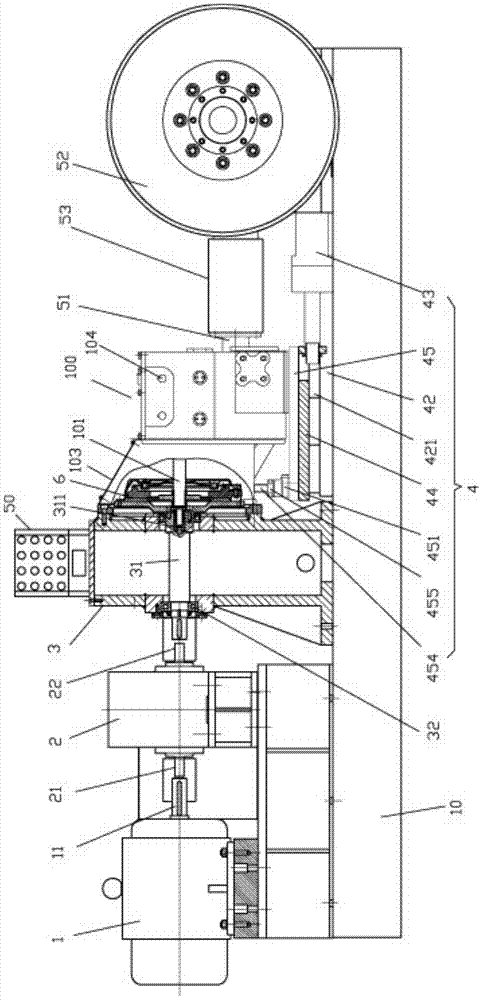

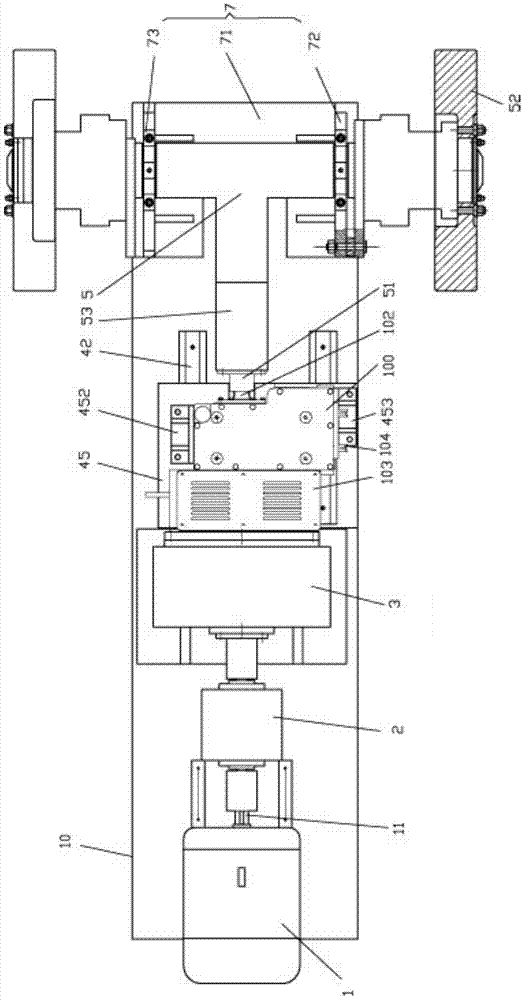

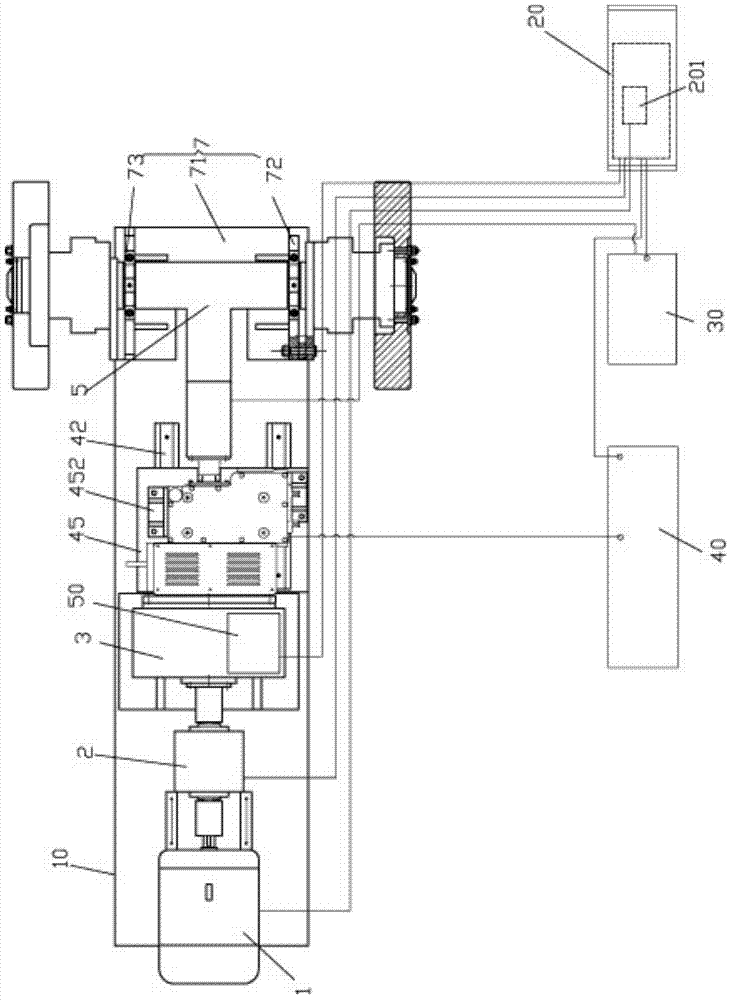

[0025] Example: see Figures 1 to 10 As shown, a gearbox test bench includes a bench platform 10, a power control box 20, a hydraulic station 30 and a mechanical oil tank 40, and the bench platform 10 is sequentially provided with a motor 1 and a torque sensor from left to right 2. The mounting base 3, the floating fixed frame 4 and the drive axle 5, the motor output shaft 11 of the motor 1 is connected with the left input shaft 21 of the torque sensor 2 through a coupling, and the right output shaft 22 of the torque sensor 2 is connected through a coupling. The shaft device is connected to the left end of the main shaft 31 hinged on the mounting seat 3, and the clutch assembly 6 is fixed on the right end of the main shaft 31;

[0026] The structure of the floating fixed frame 4 is that a slide rail 42 and a hydraulic cylinder 43 are sequentially fixed on the platform platform 10 on the right side of the mounting base 3 from left to right, and a slide block 421 is sleeved on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com