Positioning and conveying device of circuit board rubber coating machine

A conveying device and circuit board technology, applied in the directions of printed circuits, conveyor objects, transportation and packaging, etc., can solve the problems of resistance influence, difficulty in adapting to circuit boards of different widths, etc., and achieve the effect of improving the accuracy of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

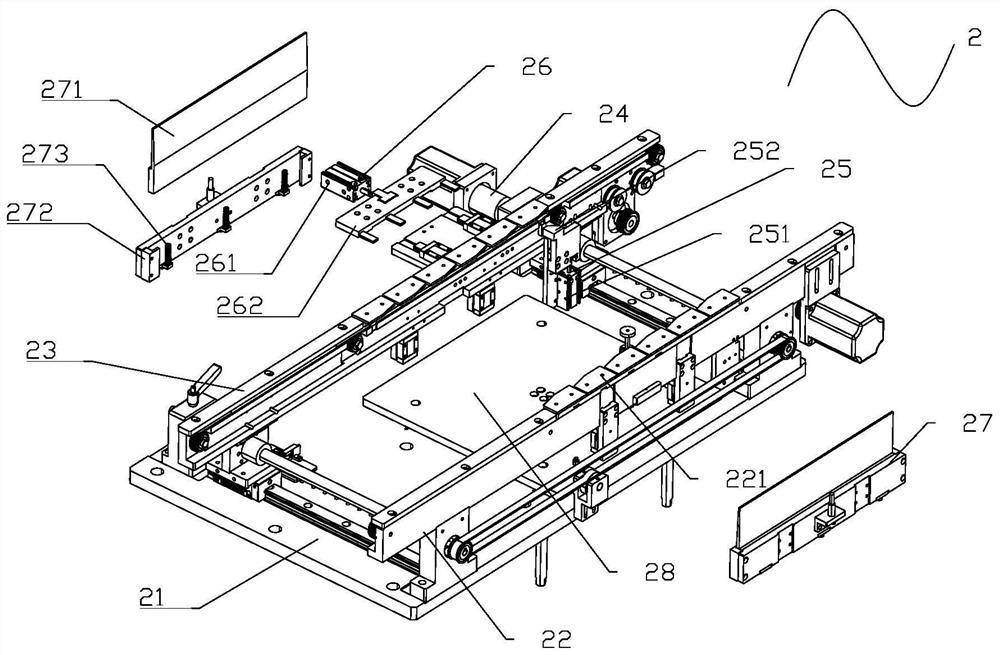

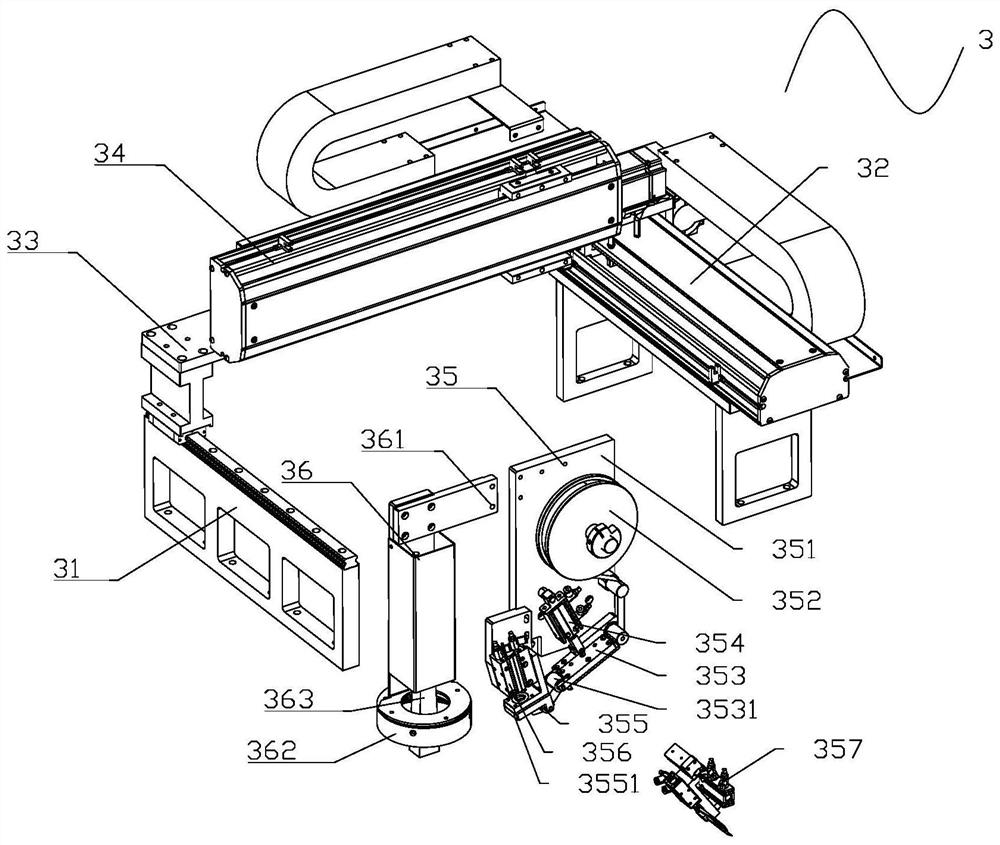

[0023] like Figure 1-Figure 6 As shown, a circuit board gluing equipment includes a frame 1 and a delivery device 2 installed on the frame 1, a gluing device 3 and a gluing device 4; the delivery device 2 is arranged at the middle part of the frame 1, and the described The gluing device 3 is located above the conveying device 2, and the discharge end of the conveying device 2 is connected with the gluing device 4; the conveying device 2 is used to place the circuit board and transport the circuit board, and the gluing device 3 is used for In order to apply adhesive paper to the edge of the circuit board, the glue coating device 4 is used to wrap the adhesive paper on the edge of the circuit board. The conveying device 2 mentioned above is a positioning conveying device of the circuit board gluing equipment.

[0024] like Figure 2-Figure 6 As shown, the positioning and conveying device of a circuit board gluing equipment includes a substrate 21, a first side rail assembly 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com