Rubberizing device of circuit board rubberizing machine

A glue sticking device and circuit board technology, which is applied to printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as difficult operation, and achieve the effects of avoiding the influence of resistance, improving positioning accuracy, and improving pasting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

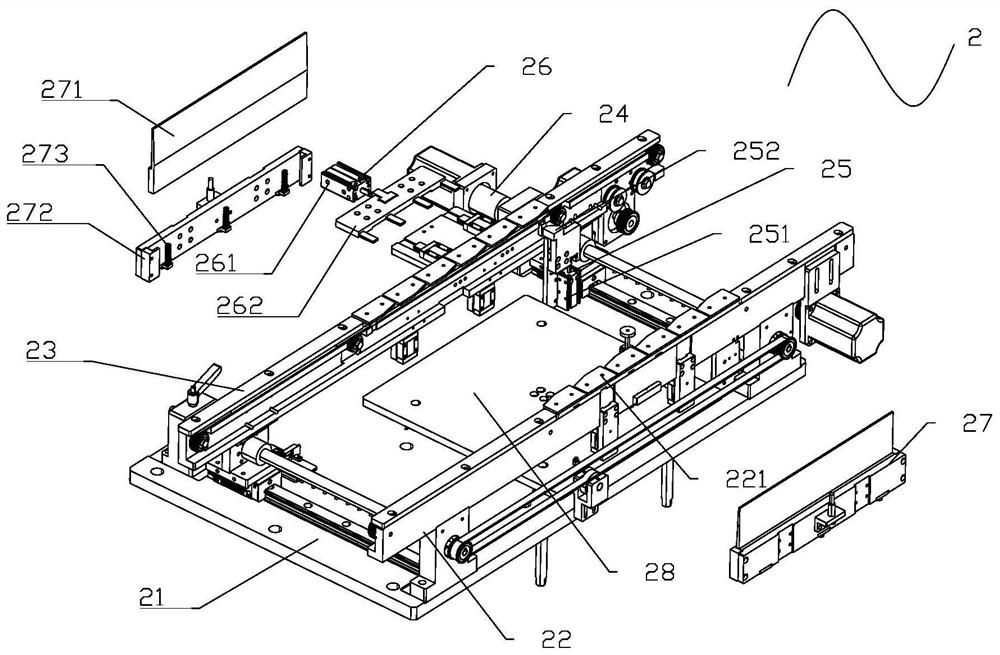

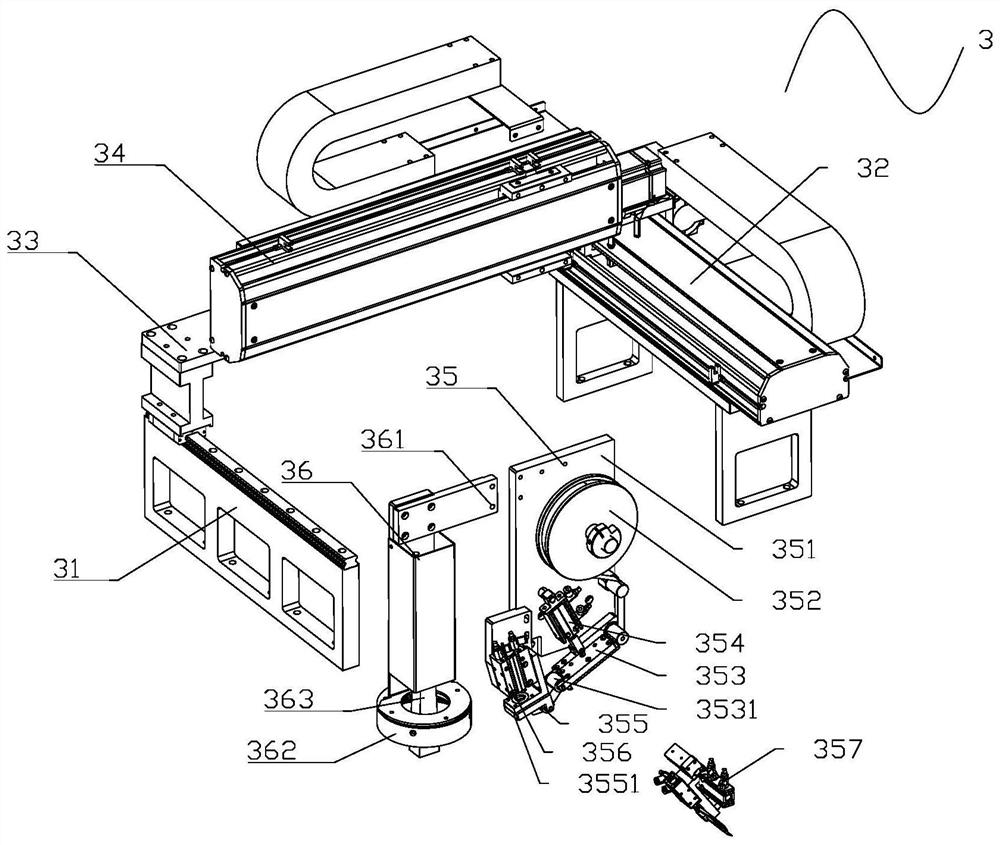

[0024] Such as Figure 1-Figure 6 As shown, a circuit board gluing machine includes a frame 1 and a delivery device 2 installed on the frame 1, a gluing device 3 and a gluing device 4; the delivery device 2 is arranged at the middle part of the frame 1, and the described The gluing device 3 is located above the conveying device 2, and the discharge end of the conveying device 2 is connected with the gluing device 4; the conveying device 2 is used to place the circuit board and transport the circuit board, and the gluing device 3 is used for In order to apply adhesive paper to the edge of the circuit board, the glue coating device 4 is used to wrap the adhesive paper on the edge of the circuit board. The above-mentioned gluing device 3 is a gluing device of a circuit board gluing machine.

[0025] Such as Figure 2-Figure 6 As shown, the conveying device 2 includes a base plate 21, a first side rail assembly 22, a second side rail assembly 23, a screw assembly 24, an end stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com