A method for automatically tidying and selecting papers

An automatic technology for paper products, applied in the field of quality inspection and finishing of the papermaking process, which can solve the problems that the detection capability cannot eliminate Class A and Class B paper defects, and cannot meet the quality requirements, so as to meet the requirements of transshipment or storage, and improve the delivery qualification. rate, the effect of improving the quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

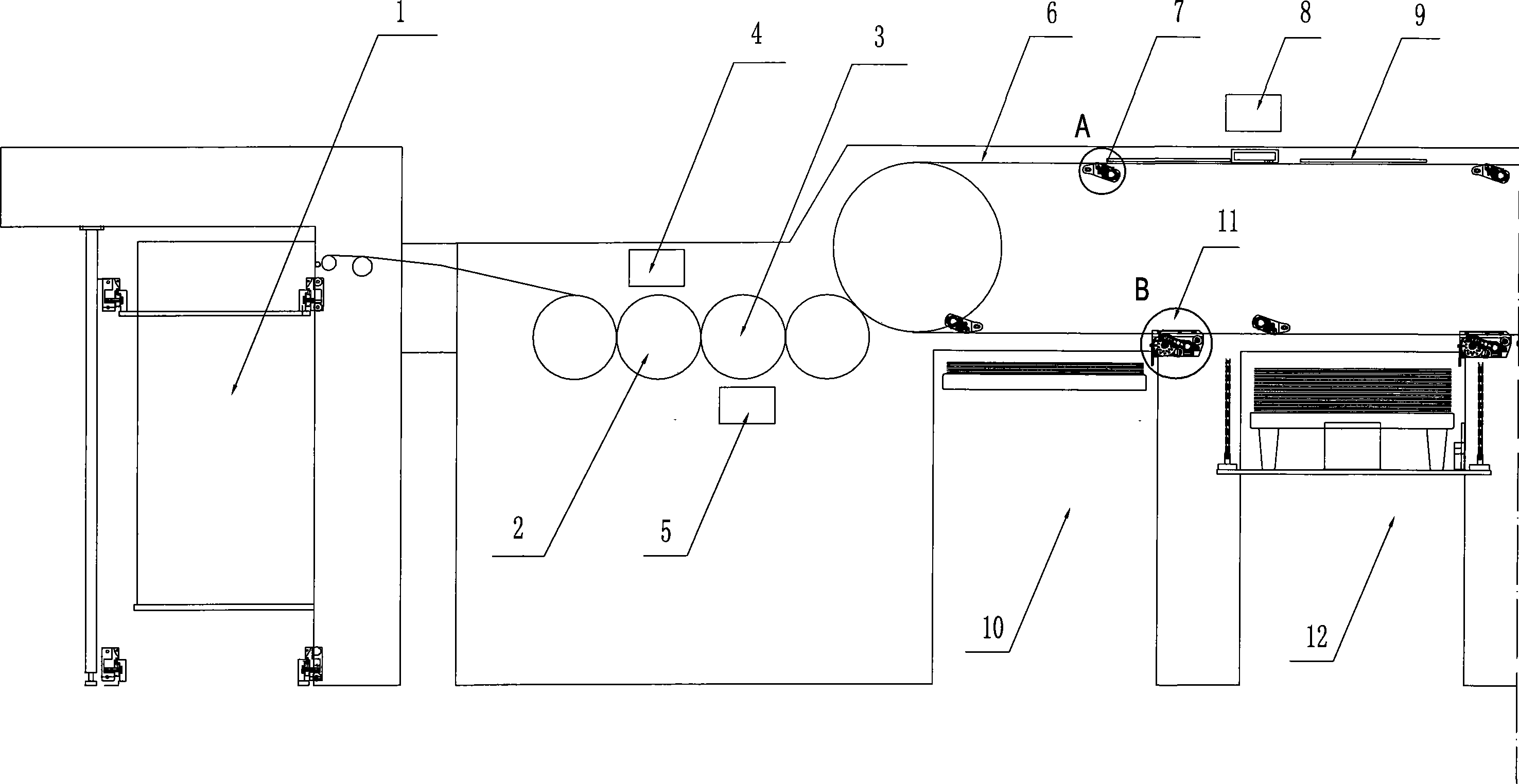

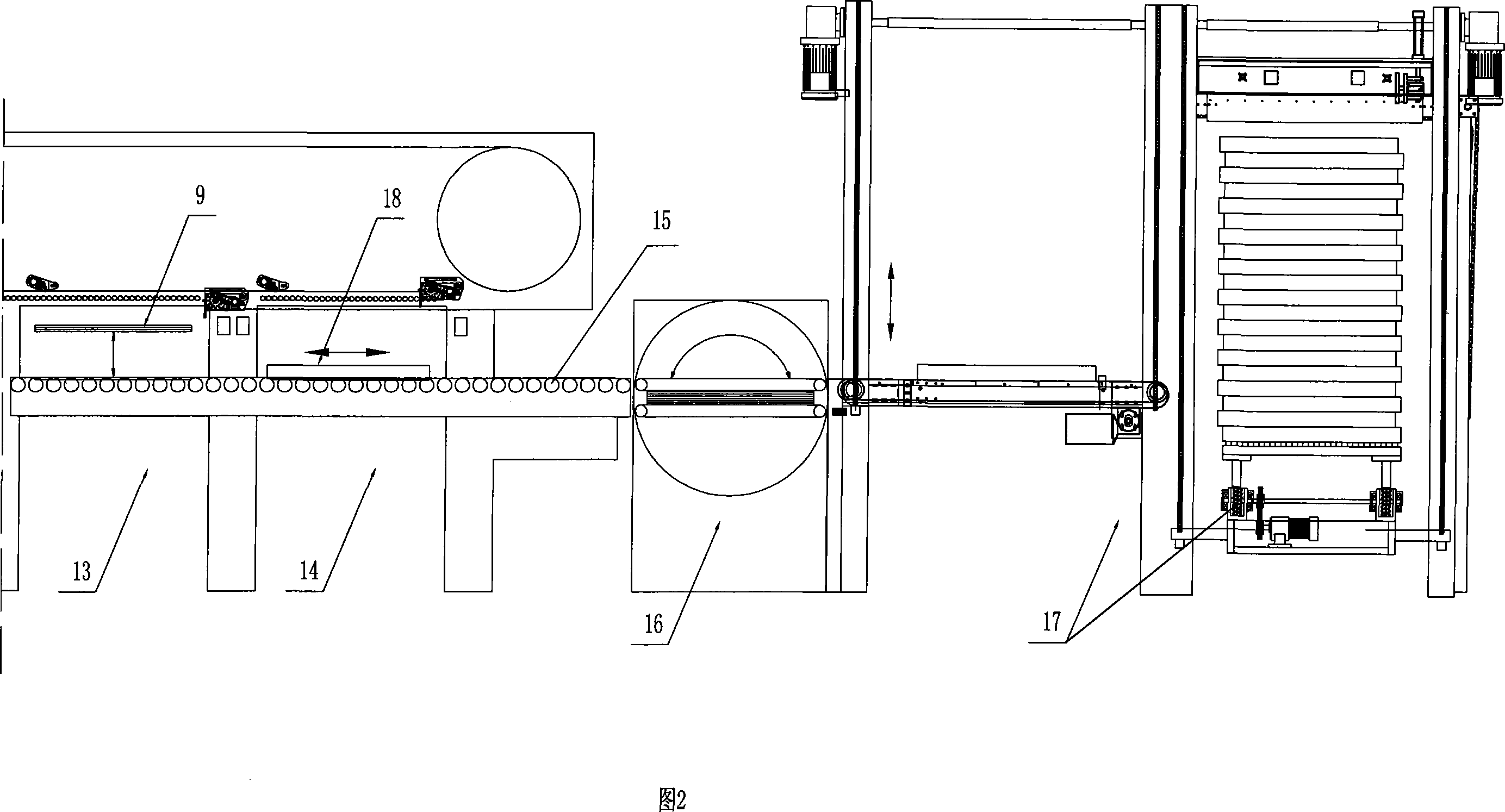

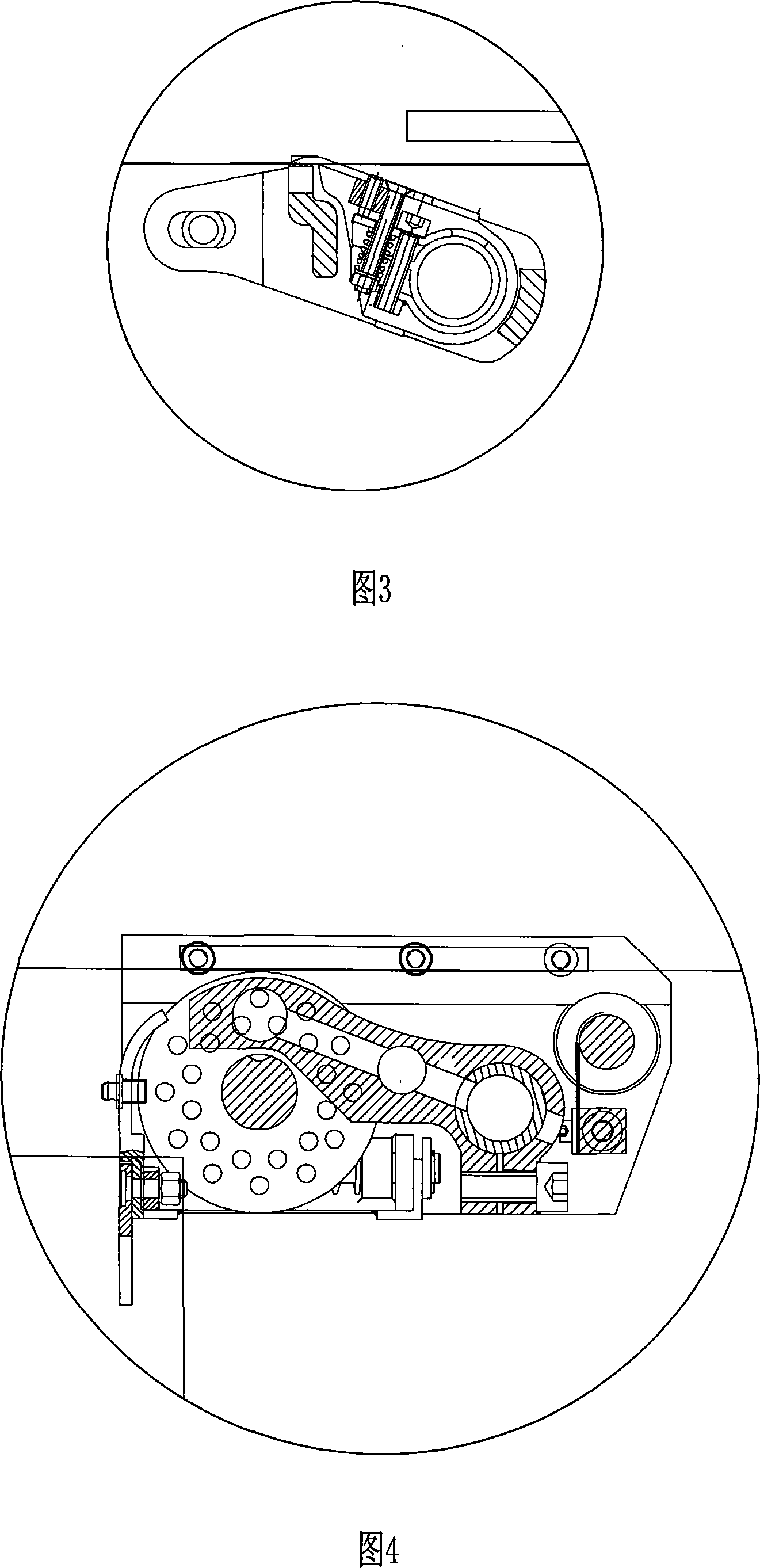

[0030] Embodiment 1: as shown in Figure 1 and Figure 2, the method for automatic selection of paper products comprises the following steps:

[0031] a. Use the paper feeder to output the patted paper products in the form of single paper products;

[0032] b. At the exit end of the paper feeder, use the computer vision processing system to inspect the appearance quality of the single paper product, including front inspection and back inspection;

[0033] c. Use the computer vision processing system to inspect the appearance quality of the sheet-fed paper products, mainly using the perspective inspection in the form of area array and line array;

[0034] d. Count and sort individual paper products;

[0035] e. Organize qualified single-sheet paper products into orders;

[0036] f. Ream paper output;

[0037] g0. Turn the paper over;

[0038] g. Ream paper palletizing.

[0039] The specific process of each step is as follows:

[0040] Step a: Decompose the pattered paper pr...

Embodiment 2

[0052] Embodiment 2: the method for automatic selection of paper products comprises the following steps:

[0053]a. Use the paper feeder to output the patted paper products in the form of single paper products;

[0054] b. At the exit end of the paper feeder, use the computer vision processing system to inspect the appearance quality of the single paper product, including front inspection and back inspection;

[0055] c. Use the computer vision processing system to inspect the appearance quality of the sheet-fed paper products, mainly using the perspective inspection in the form of area array and line array;

[0056] d. Count and sort individual paper products;

[0057] e. Organize the qualified paper products into shots;

[0058] f. Finished paper output.

[0059] The specific process of steps a, b, c, and d in this embodiment is as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com