Measurement commission management system and method for wharf material unloading

The technology of a management system and management method is applied in the field of material unloading metering entrustment management system at the terminal, which can solve the problems of confusing measurement, low work efficiency, heavy weight, etc., so as to reduce the loss of purchased materials, improve work efficiency, and improve utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

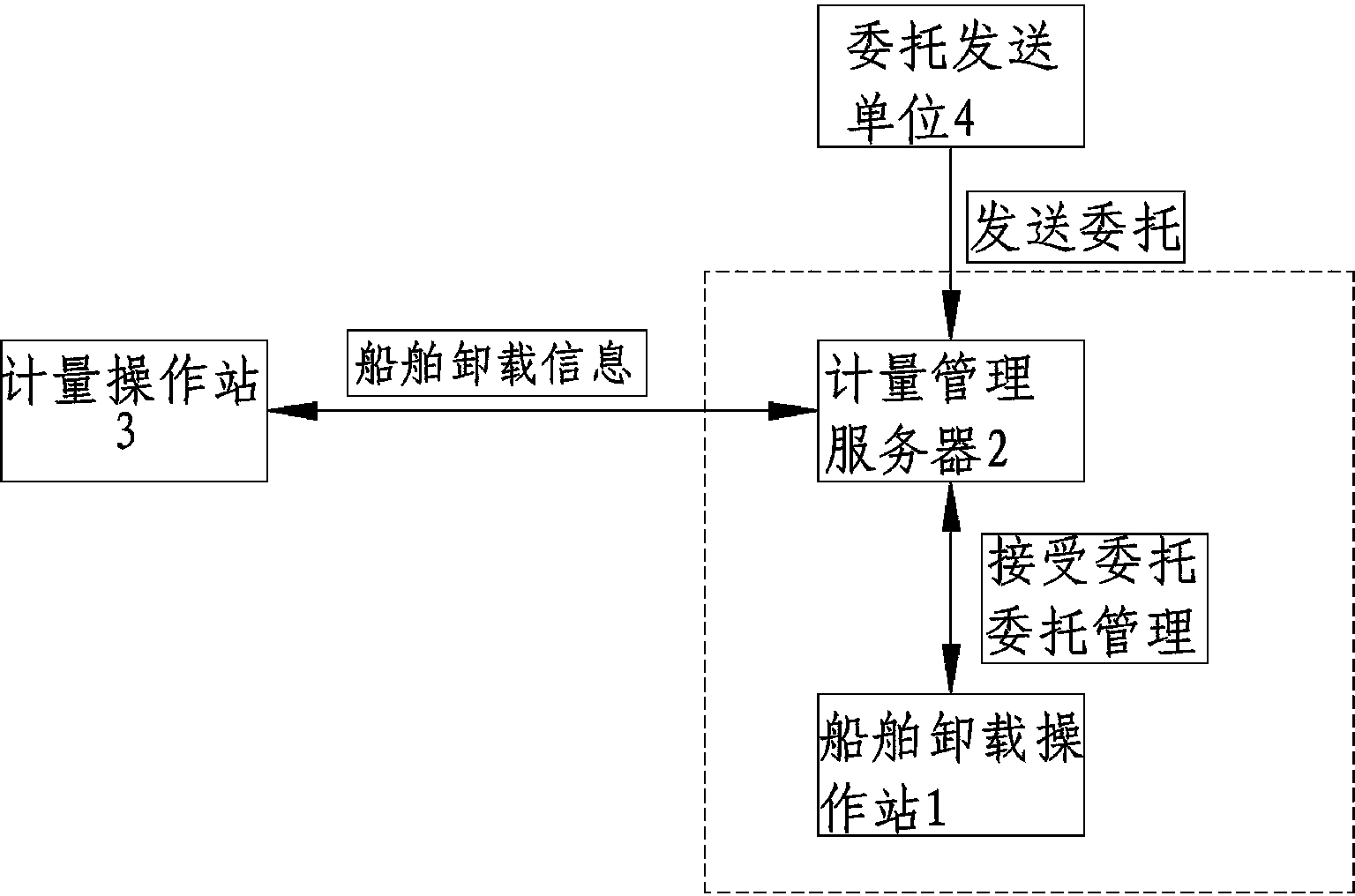

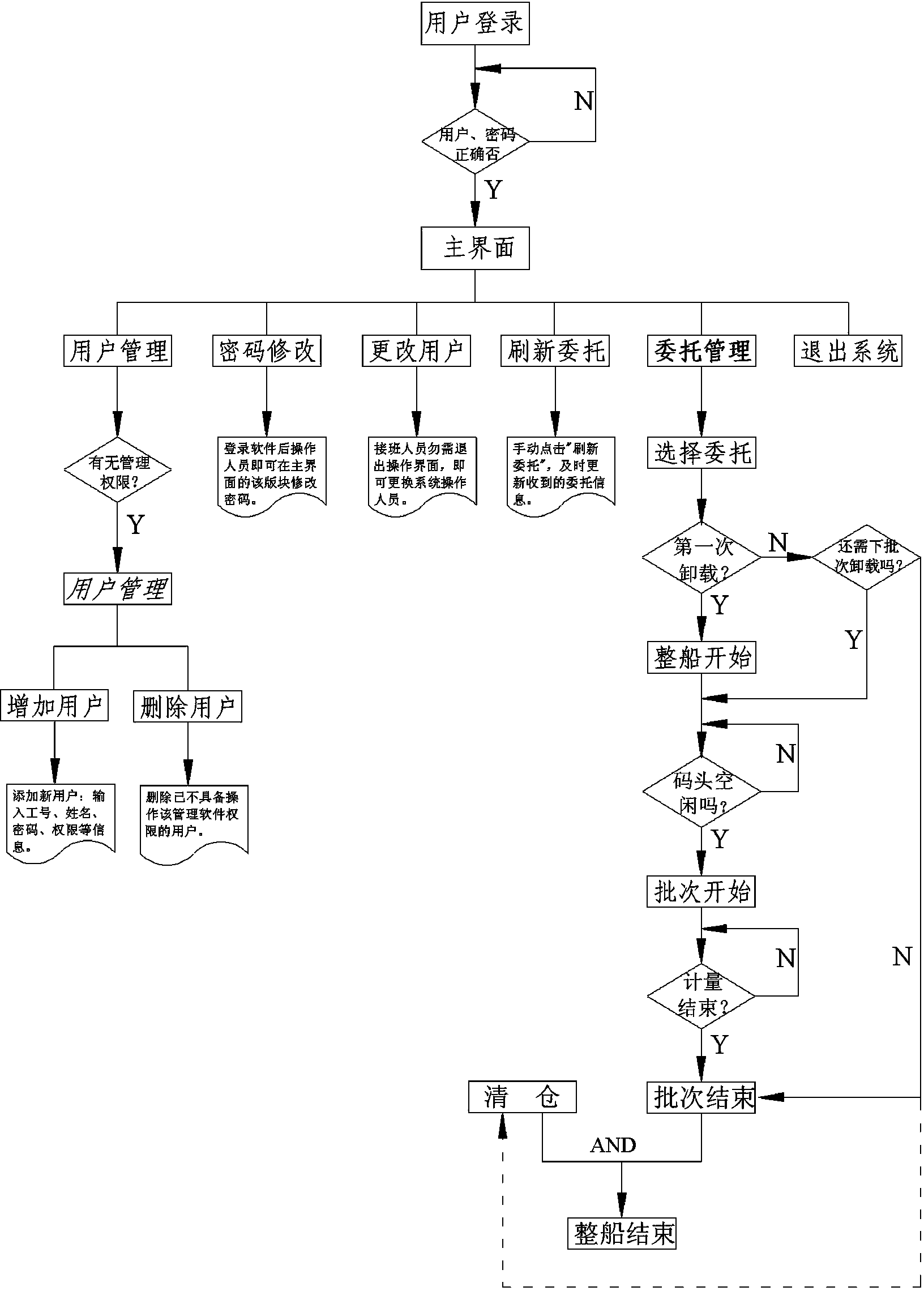

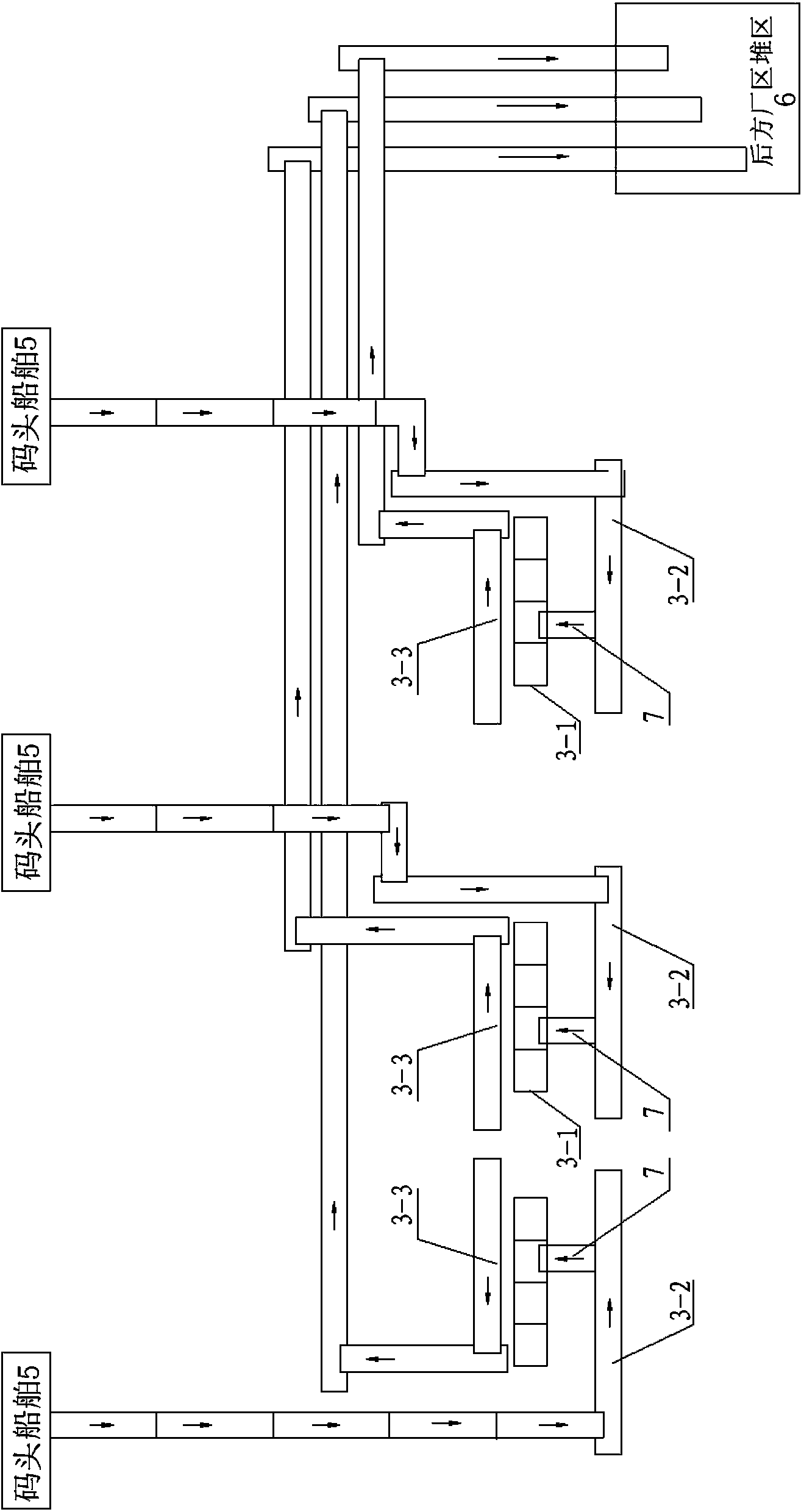

[0038] see Figures 1 to 3A metering entrusted management system for dock material unloading shown includes a ship unloading operation station 1, a metering management server 2 and a metering operation station 3, the metering management server 2 adopts the Oracle10g database system, and the server operating system is Windows Server 2008 32 bits; The ship unloading operation station 1 is a set of industrial control computers, and the industrial control computer is installed with entrusted measurement management software. The user can retrieve and manage the information of the entrusted ship to be unloaded by the ship unloading operation station 1, and control the unloading of ship materials. Start and end time, dispatch ship unloading dock, industrial control computer adopts Microsoft Visual Basic 6.0 development tool, develop and design based on Windows XP system; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com