Inoculator of edible fungus

A technology of edible fungus and inoculator, which is applied in application, heating, gardening, etc. It can solve the problems that farmers cannot master, the number of operations is limited, and the dosage is difficult to control, so as to reduce labor intensity, high inoculation success rate, and consistent inoculation amount Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

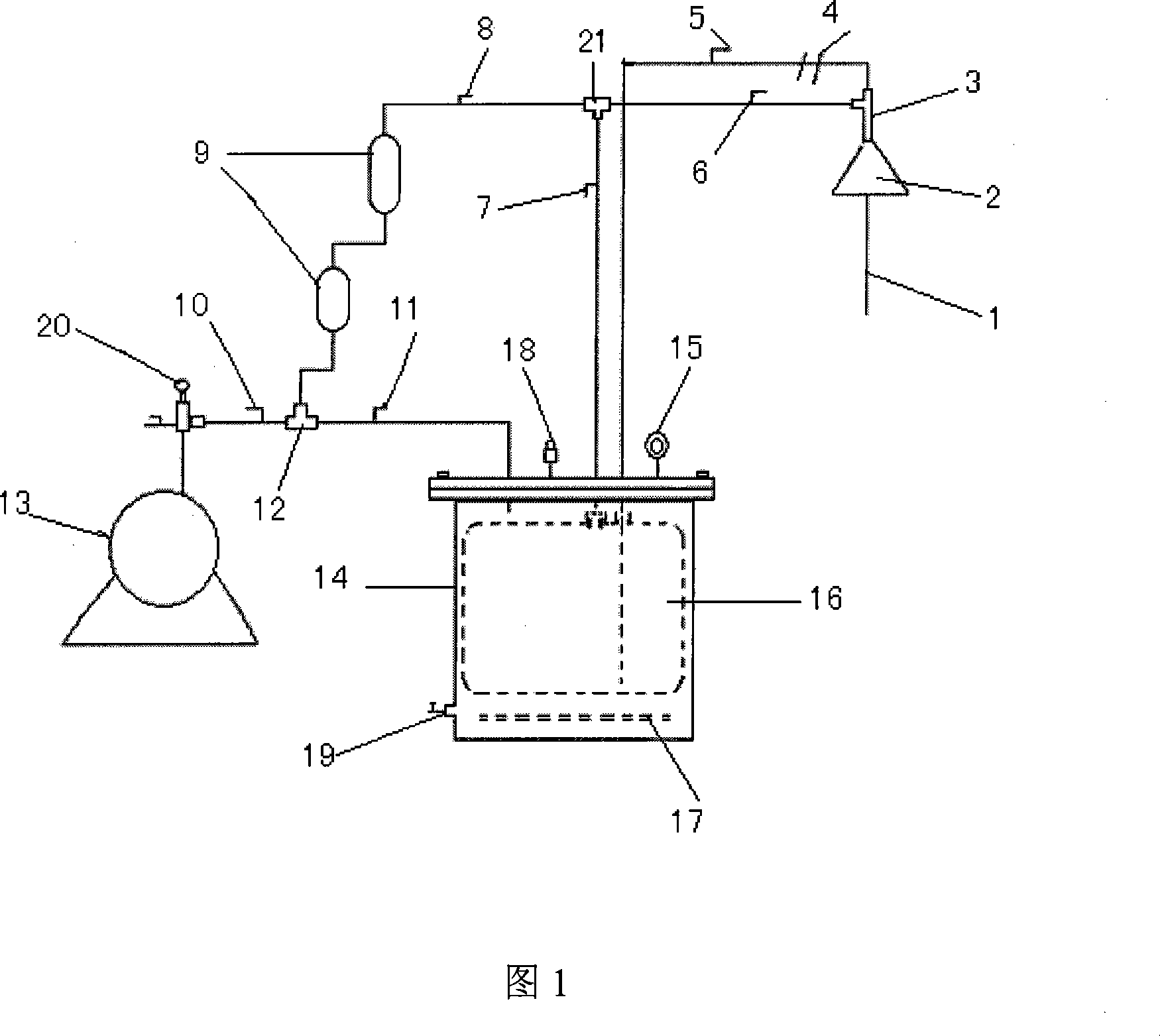

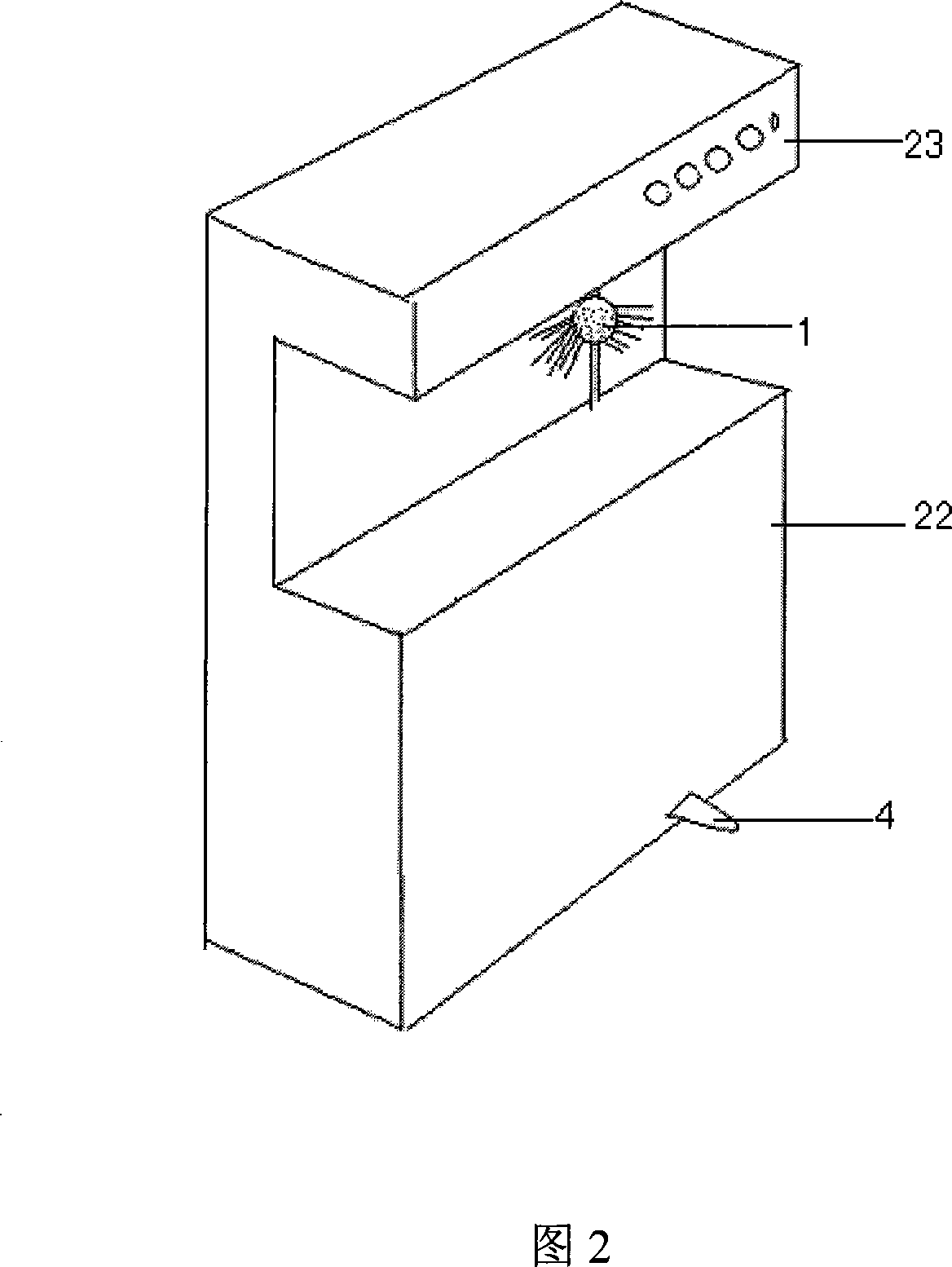

[0017] Further illustrate the present invention below in conjunction with accompanying drawing.

[0018] With reference to Fig. 1, edible fungus inoculator comprises steam pressure tank 14, gas compressor 13, two gas filters 9 connected in series, gas distributor 2 and bacterial classification storage tank 16, be provided with electric heating pipe in steam pressure tank 14 17. The upper cover of the steam pressure tank 14 is provided with a pressure gauge 15, a safety valve 18 and two steam outlets. The lower part of the steam pressure tank 14 has a drain valve 19. One steam outlet of the steam pressure tank 14 passes through the first valve 11 and the second steam outlet. One port of the three-way 12 is connected, the other port of the first three-way 12 is connected with the gas compressor 13 through the second valve 10 and the adjustment pressure reducing valve 20, and the third port of the first three-way 12 is connected with the serial One end of the gas filter 9 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com