Efficient frame grabbing structure

A frame-grabbing and efficient technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of frame jamming and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

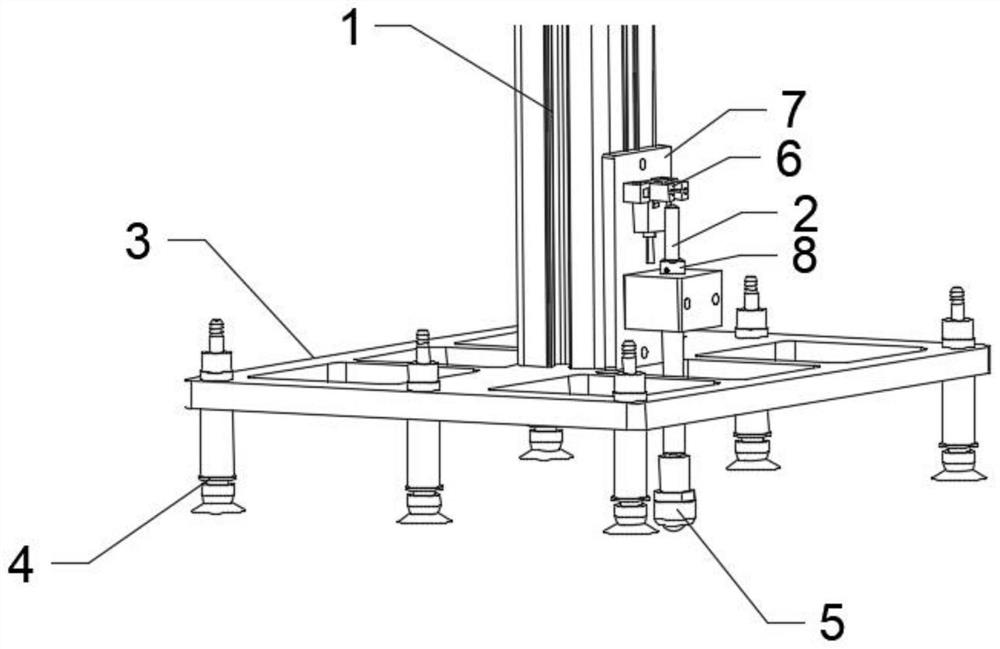

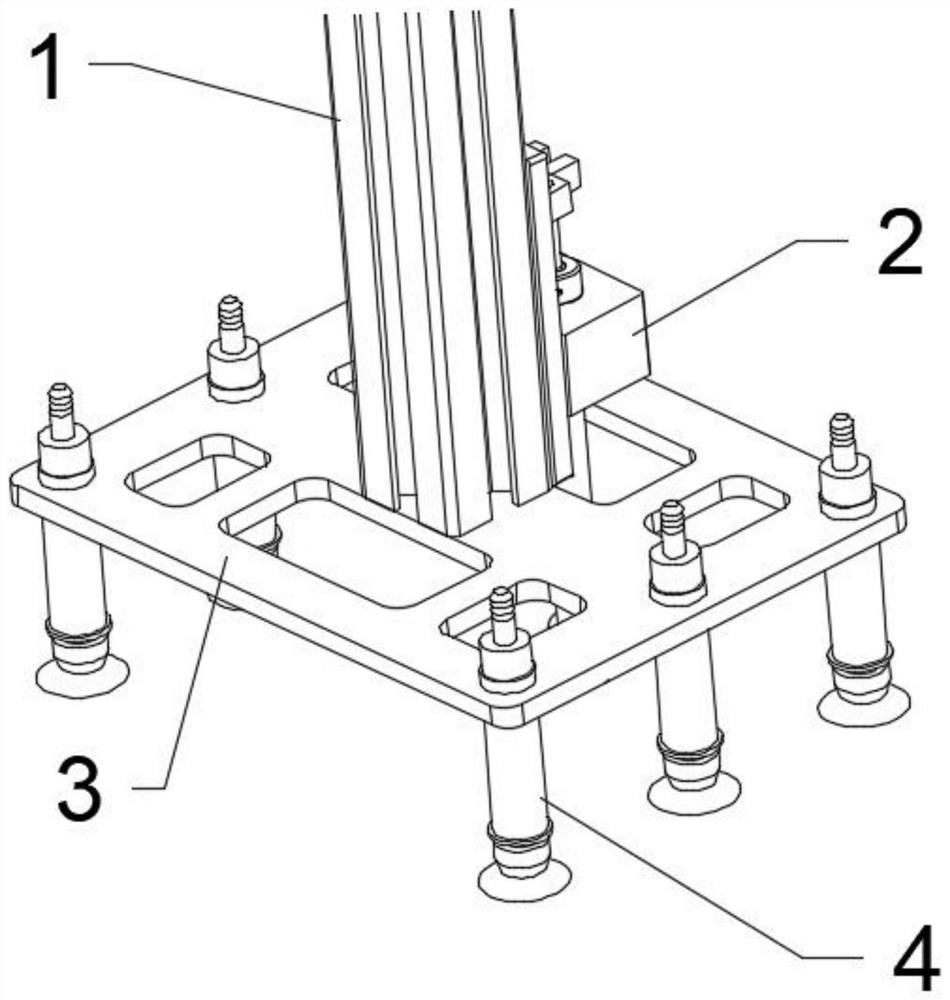

[0017] Such as Figure 1-2 As shown, the present invention proposes a high-efficiency grasping frame structure, including a fixed support 1, a suction cup support 3 and a miniature vacuum suction cup 4, the fixed support 1 is vertically connected with the suction cup support 3, and the miniature vacuum suction cups 4 are distributed at both ends of the suction cup support 3, and fixed A probe rod bracket 7 is arranged on the bracket 1, a sensor probe rod 2 is installed on the probe rod bracket 7, a U-shaped photoelectric sensor 6 is installed on the upper part of the probe rod bracket 7, the U-shaped photoelectric sensor 6 is perpendicular to the sensor probe rod 7, and the sensor probe rod The rod head of 7 is aligned with the opening part of U-shaped photoelectric sensor 6, and the lower end of sensor probe rod 2 is connected with universal ball 5.

[0018] When grabbing materials, the sensor probe rod 2 extends downwards. When the universal ball 5 touches the material frame...

Embodiment 2

[0020] Based on Example 1, such as Figure 1-2 As shown, the suction cup bracket 3 is provided with an opening, and the sensor probe rod 2 passes through the opening part on the suction cup bracket 3 vertically. friction with the opening wall.

Embodiment 3

[0022] Based on Example 1, such as Figure 1-2 As shown, the height of the position of the universal ball 5 is lower than that of the miniature vacuum suction cup 4, and the position of the universal ball 5 is lower, so that it is easy to touch the material frame first. When the material frame is not normal, the universal ball 5 will first level the material frame. Then the miniature vacuum chuck 4 realizes grabbing frame again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com