A wood block punching device for solid wood sofa processing

A technology of wooden blocks and sofas, which is applied in the direction of wood processing equipment, manufacturing tools, bark area/debris/dust/waste removal, etc., which can solve problems such as misalignment, sore arms, injuries, etc., and prevent excessive upward movement distance big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

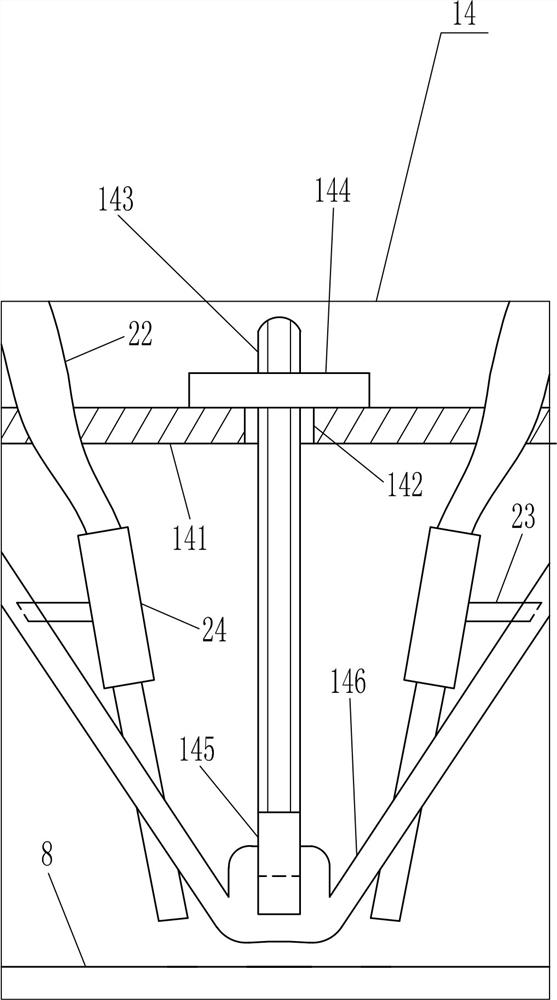

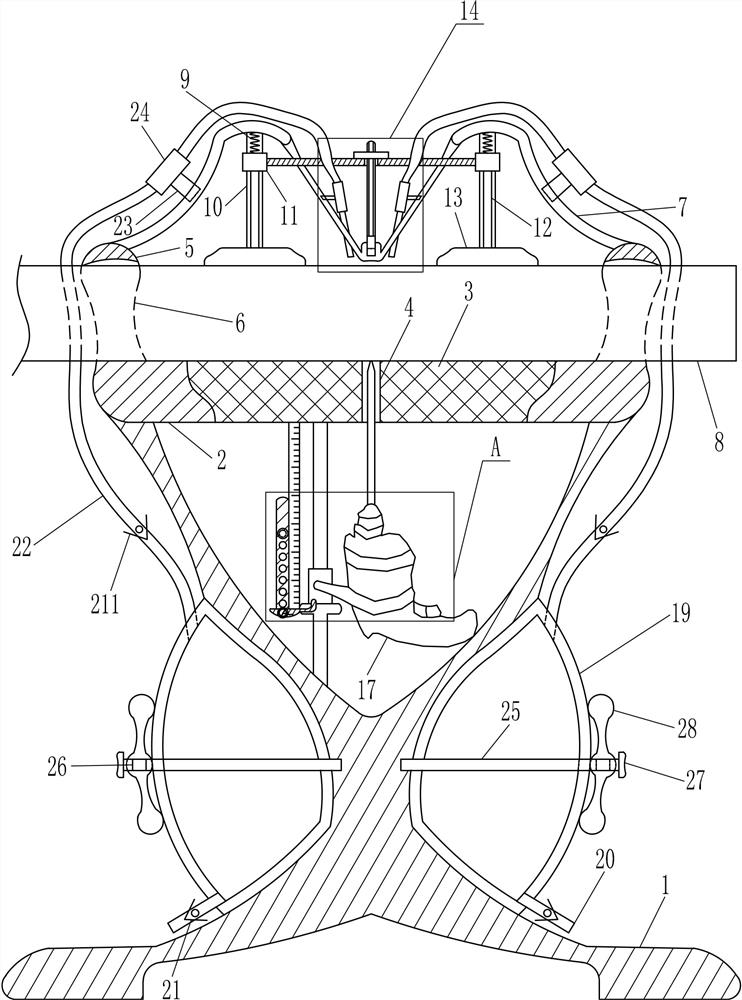

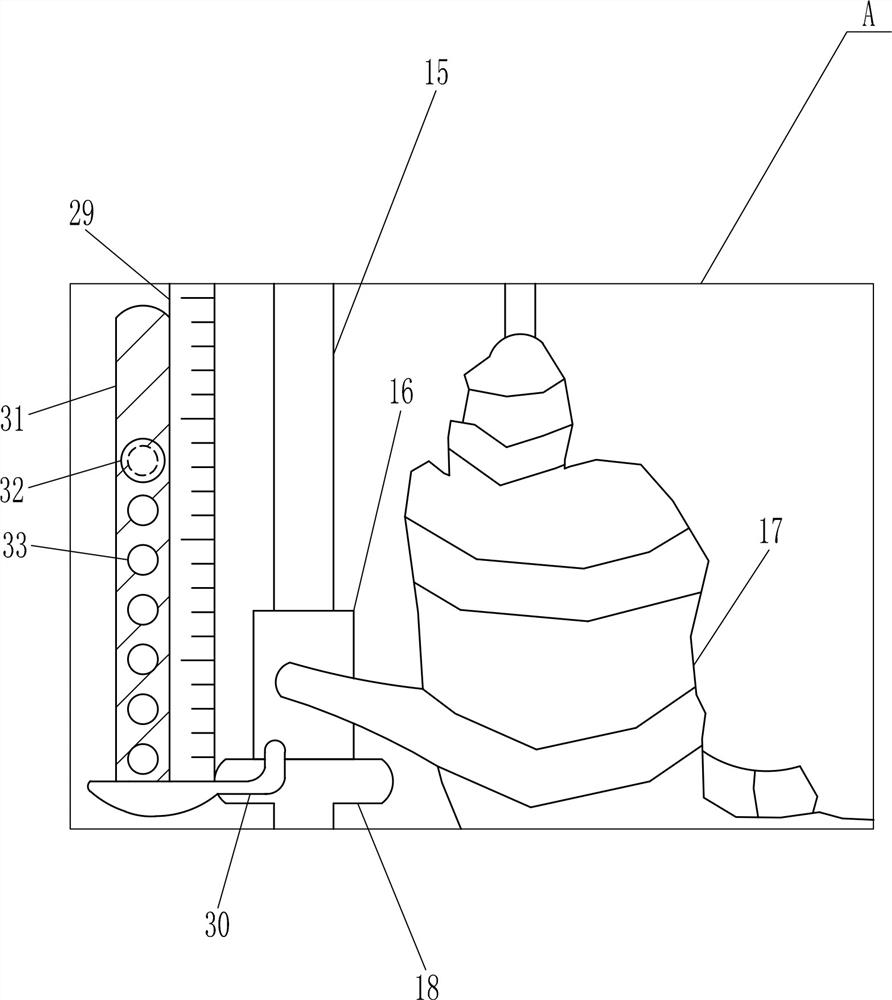

[0016] A kind of wooden block punching instrument for solid wood sofa processing, such as Figure 1-3 As shown, it includes a mounting frame 1, a placement block 2, a filter screen 3, a first pillar 5, a first connecting rod 7, a spring 9, a first slide rail 10, a first slider 11, a pole 12, and a pressure block 13 , adjustment mechanism 14, guide rail 15, sliding sleeve 16, electric drill 17 and second pillar 18, the top of mounting frame 1 is provided with placing block 2, and mounting frame 1 is connected with placing block 2 by the mode of welding connection, and the middle part of placing block 2 is provided with The filter screen 3 has a guide hole 4 in the middle of the filter screen 3, and the left and right sides of the top of the placement block 2 are symmetrically provided with the first pillar 5. The placement block 2 is connected with the first pillar 5 by welding, and the bottom of the first pillar 5 is opened. There are jacks 6, and a wooden block body 8 is plac...

Embodiment 2

[0018] A kind of wooden block punching instrument for solid wood sofa processing, such as Figure 1-3 As shown, it includes a mounting frame 1, a placement block 2, a filter screen 3, a first pillar 5, a first connecting rod 7, a spring 9, a first slide rail 10, a first slider 11, a pole 12, and a pressure block 13 , adjusting mechanism 14, guide rail 15, sliding sleeve 16, electric drill 17 and second pillar 18, the top of mounting frame 1 is provided with placement block 2, and the middle part of placement block 2 is provided with filter screen 3, has guide hole 4 in the middle of filter screen 3, The left and right sides of the top of the placement block 2 are symmetrically provided with a first pillar 5, the bottom of the first pillar 5 has a jack 6, and a wooden block body 8 is placed in the left and right side jacks 6, and the bottom of the wooden block body 8 is connected to the top of the placement block 2. Contact, the top of the first pillar 5 on the left and right s...

Embodiment 3

[0021] A kind of wooden block punching instrument for solid wood sofa processing, such as Figure 1-3As shown, it includes a mounting frame 1, a placement block 2, a filter screen 3, a first pillar 5, a first connecting rod 7, a spring 9, a first slide rail 10, a first slider 11, a pole 12, and a pressure block 13 , adjusting mechanism 14, guide rail 15, sliding sleeve 16, electric drill 17 and second pillar 18, the top of mounting frame 1 is provided with placement block 2, and the middle part of placement block 2 is provided with filter screen 3, has guide hole 4 in the middle of filter screen 3, The left and right sides of the top of the placement block 2 are symmetrically provided with a first pillar 5, the bottom of the first pillar 5 has a jack 6, and a wooden block body 8 is placed in the left and right side jacks 6, and the bottom of the wooden block body 8 is connected to the top of the placement block 2. Contact, the top of the first pillar 5 on the left and right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com