Busbar joint mechanism of subway tunnel

A busbar and tunnel technology, applied in the field of busbar joint mechanism, can solve the problems that the anti-flooding door cannot break the wire rope, the movable joint cannot move, and the wire rope is easy to get stuck, so as to achieve good use effect, save time and improve safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

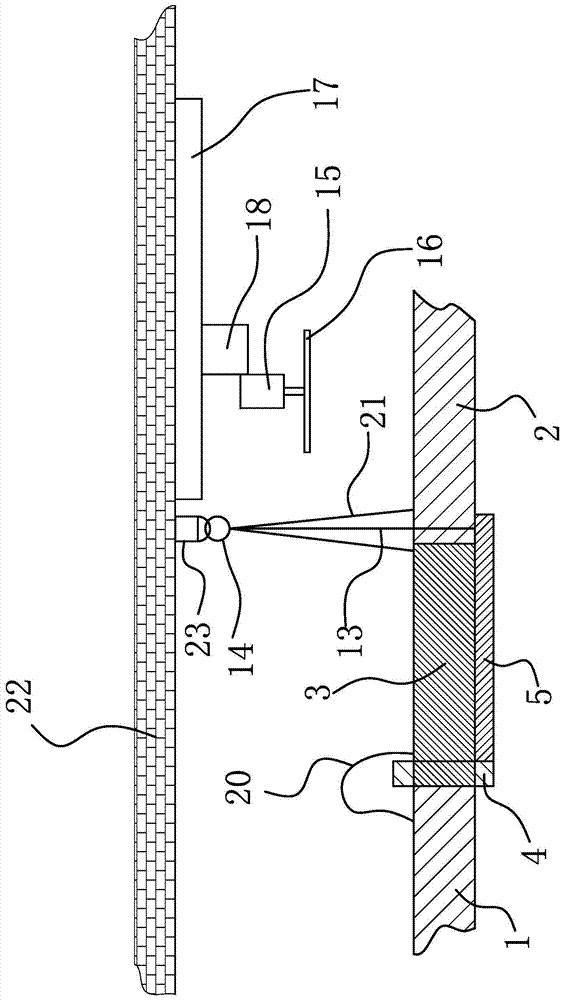

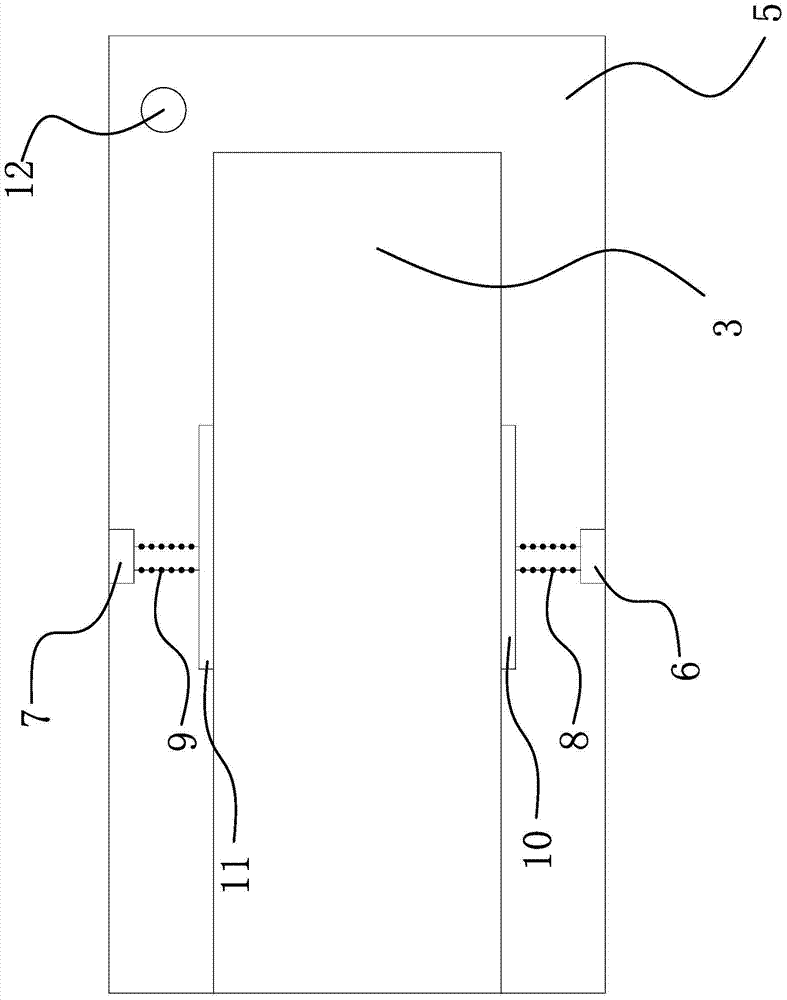

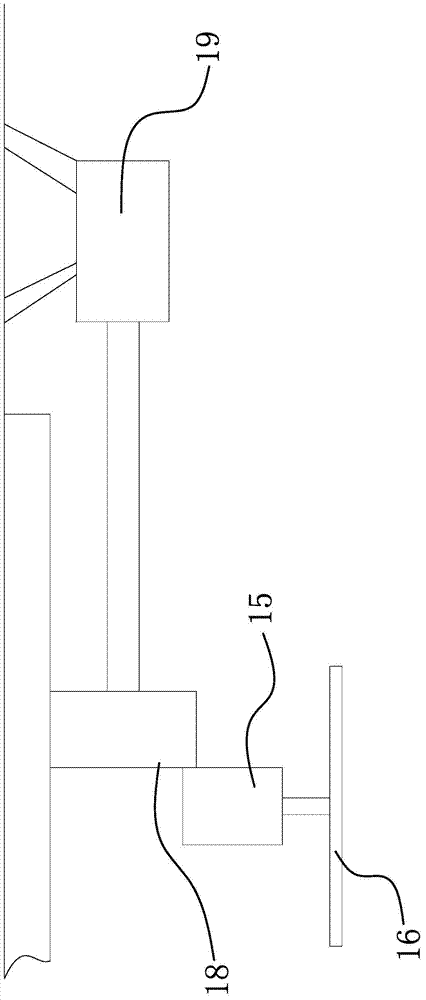

[0028] Such as figure 1 , figure 2 and image 3 As shown, the subway tunnel includes a tunnel body, and the tunnel body is provided with an anti-flooding door capable of closing the tunnel body; the bus joint mechanism includes a bus bar left section 1, a bus bar right section 2 and a In connection with the connecting section 3, the floodproof door is hinged on the inner wall of the tunnel body, the connecting section 3 is located at the closing track of the floodproof door, and the left section 1 of the busbar is fixed with a positioning plate 4, The positioning plate 4 is provided with a piercing hole, the lower part of the positioning plate 4 is hinged with a support plate 5, and the other end of the support plate 5 is provided with a support plate that can make this end of the support plate 5 lean against the right side of the bus bar. The positioning structure at the lower part of section 2, the connecting section 3 is arranged on the support plate 5, one end of the co...

Embodiment 2

[0035] The content in the second embodiment is roughly the same as that in the first embodiment, the difference is that the lower part of the positioning plate 4 in the first embodiment is vertically fixed with a mounting block 1 and a mounting block 2, and the mounting block 1 and the mounting block 2 Mounting hole 1 and mounting hole 2 are respectively opened on the mounting block 2. One end of the support plate 5 is fixed with a hinged shaft, and the mounting hole 1 and mounting hole 2 are respectively fixed with a positioning bearing 1 and a positioning bearing 2. The hinged shaft described above is arranged between the mounting block 1 and the mounting block 2, and the two ends of the hinged shaft are respectively fixed on the inner ring of the positioning bearing 1 and the inner ring of the positioning bearing 2; and in the second embodiment, The lower part of the positioning plate 4 is vertically fixed with a mounting block 1 and a mounting block 2, and the mounting bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com