A production line for fish egg spreading

A production line and fish ball technology, applied in the field of fish ball sprinkling production line, can solve the problems of no recovery of seasoning, uneven seasoning, and inability to guarantee fish eggs, etc., and achieve the effect of increasing coating efficiency and uniform fish eggs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

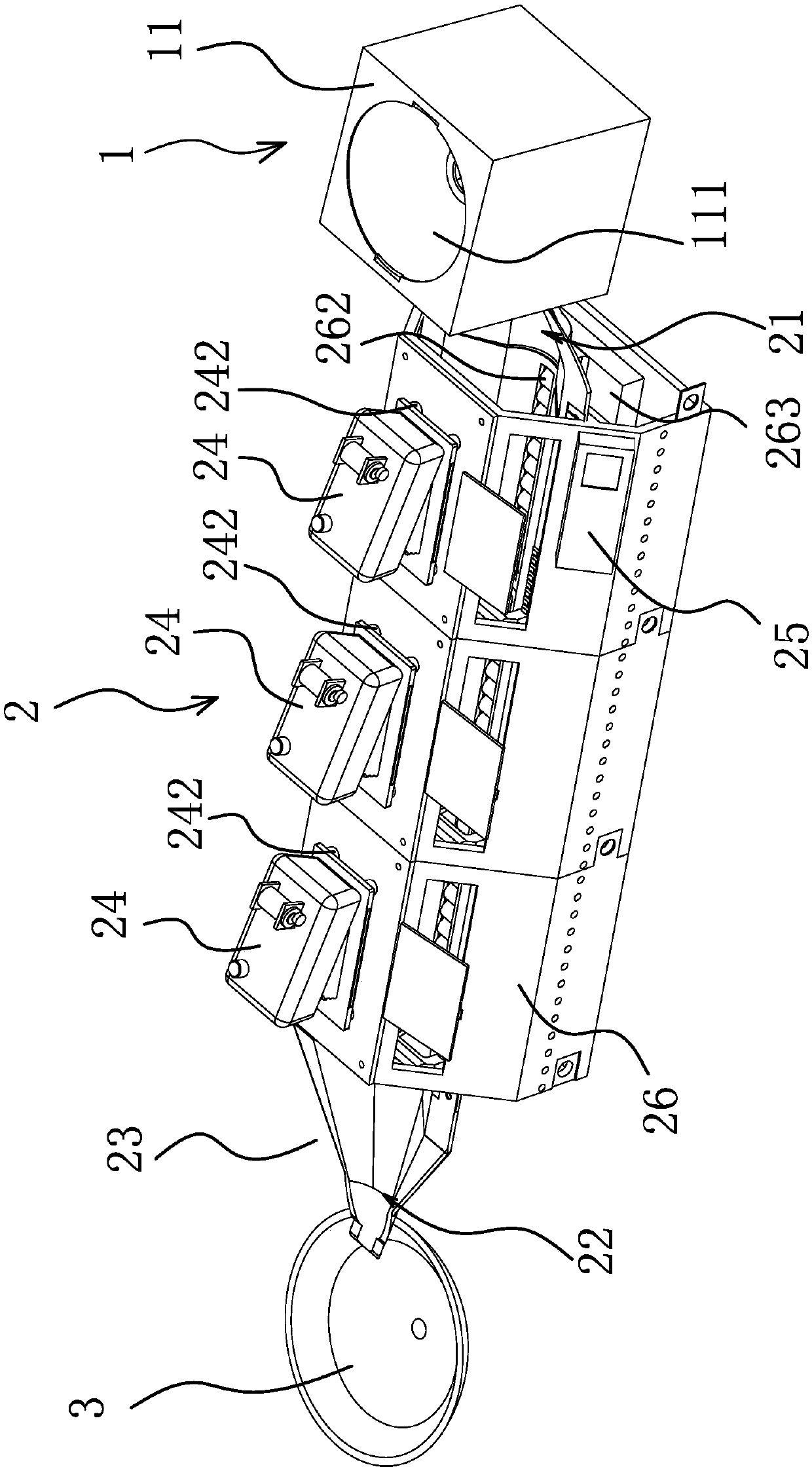

[0047] Such as figure 1 As shown, the production line used for fish egg spreading includes a feeder 1, a spreader 2 and a feeder 3. The spreader 2 includes a linear guide plate 23, and one end of the linear guide plate 23 is the feed end 21, and the straight line The other end of the guide plate 23 is the discharge end 22 , the feeder 1 is aligned with the feed end 21 of the linear guide plate 23 , and the feeder 3 is located below the discharge end 22 of the linear guide plate 23 .

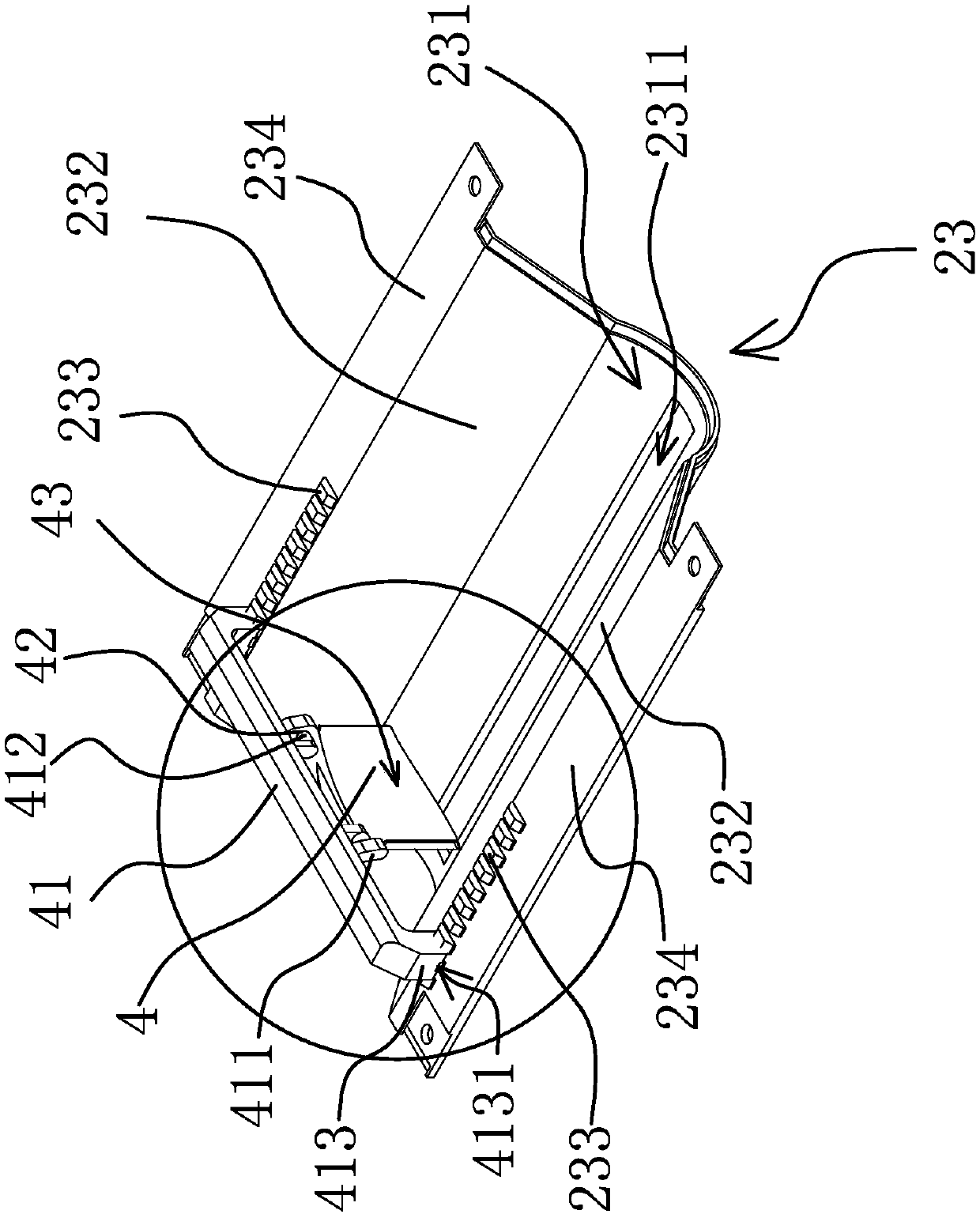

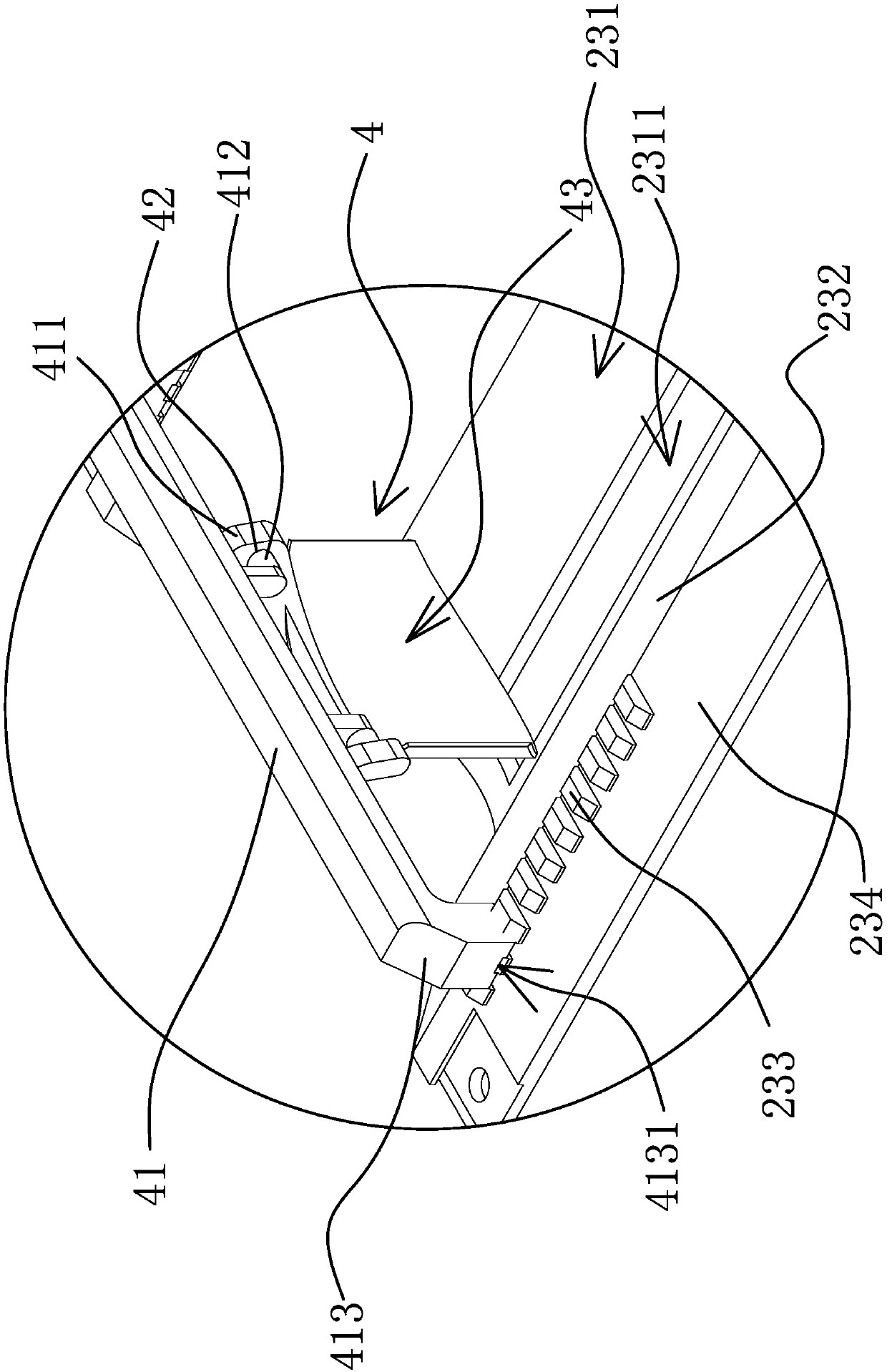

[0048] Specifically, if Figure 1-7 As shown, the material spreader 2 includes a shell 26, and a linear guide plate 23 is arranged in the shell 26. The linear guide plate 23 is inclined downward from the feed end 21 to the discharge end 22, and the linear guide plate 2 is sunken to form a guide for fish eggs to roll. Feed trough 231, linear guide plate 23 is provided with several baffle plates 4, and some baffle plates are distributed along the lengthwise direction of linear guide plate 23, and ...

Embodiment 2

[0060] The production line for fish ball spreading in this embodiment is basically the same as that in Embodiment 1, the difference is that the actuator includes a cylinder, one end of the cylinder is connected to the linear guide plate 23, and the other end of the cylinder is connected to the baffle plate 4, when When the fish eggs on one side of the baffle plate 4 reach the set value, the cylinder can drive the baffle plate 4 to move upwards.

[0061] When the fish eggs on one side of the baffle 4 reach the set value, the cylinder drives the baffle 4 to move upwards, so that the fish eggs on one side of the baffle 4 can pass through the baffle 4 and enter the material guide groove 231 of the other section Inside, make the fish balls slide to the next section in more quantity, and then make the condiment in the sprinkling box 24 can be coated on the fish balls more evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com