Textile compressor capable of packaging

A compressor and textile technology, applied in packaging and other directions, can solve the problems of affecting the effect of compression, trouble, shorten the service life of hydraulic compressors, etc., and achieve the effect of high compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The following description is used to disclose the present invention so that those skilled in the art can implement the present invention. The preferred embodiments in the following description are only examples, and those skilled in the art can think of other obvious variations.

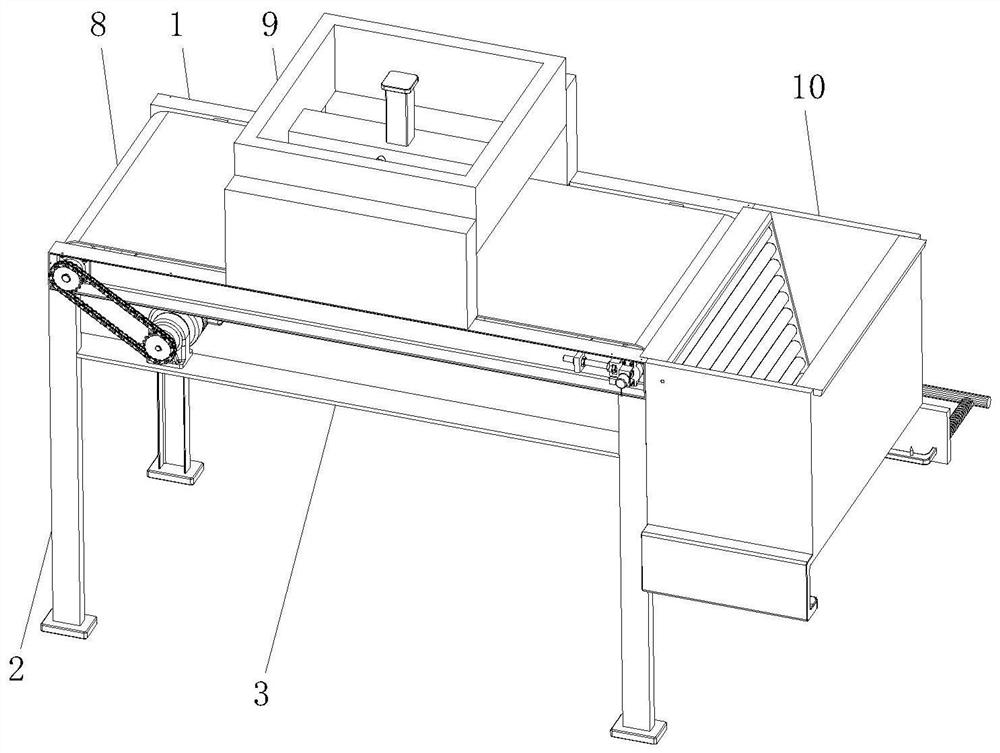

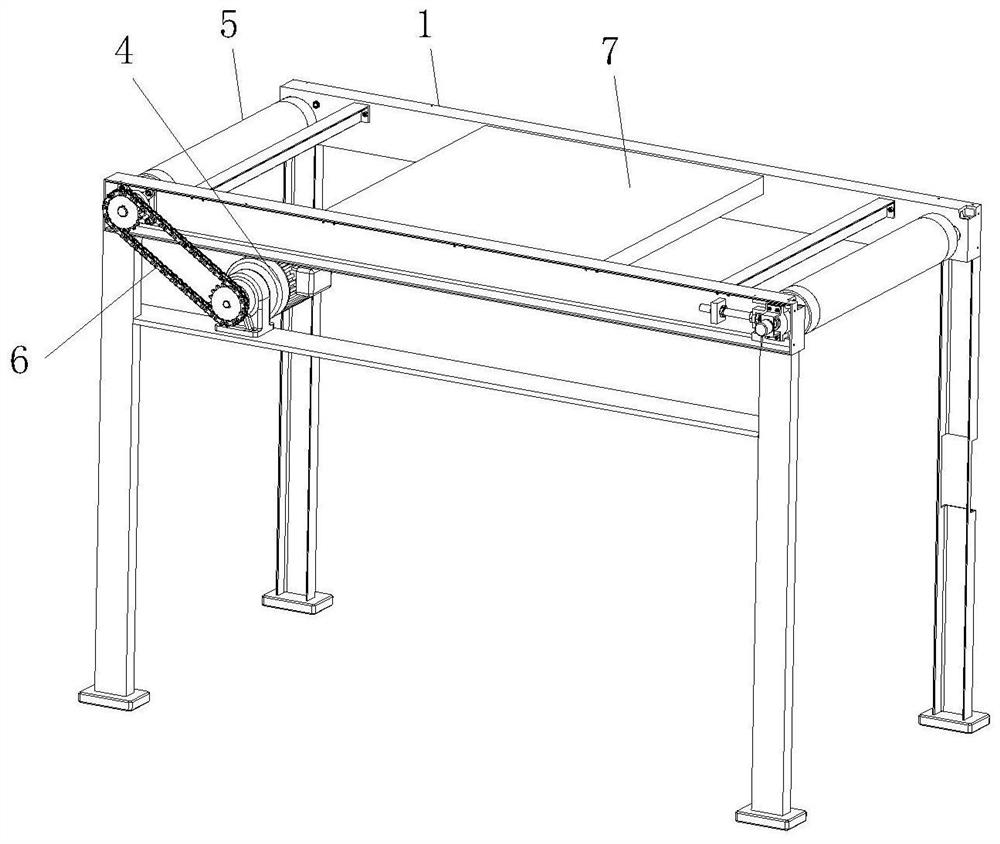

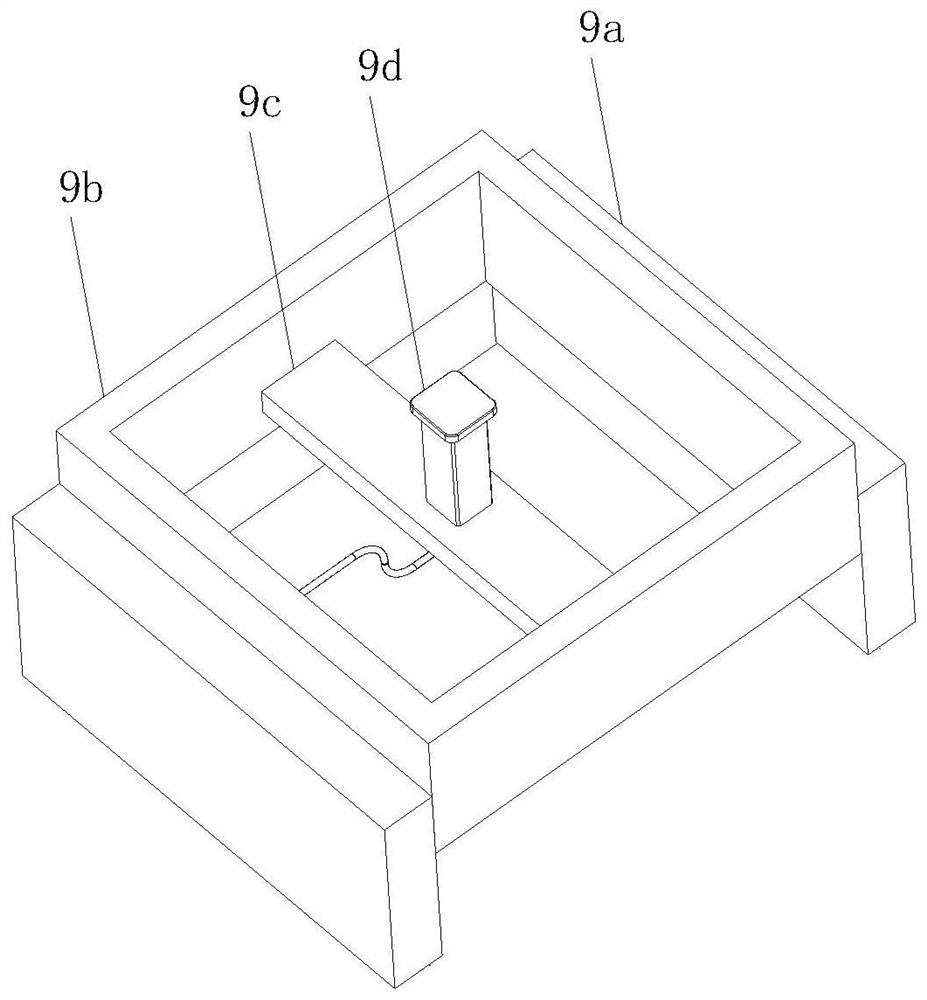

[0031]SeeFigure 1-9, A textile compressor that can be packaged, including a base conveying body 1, a supporting foot 2 is provided at the lower end of the conveying body 1, a mounting plate 3 is fixedly mounted on the inner side of the supporting foot 2, and a driving motor is fixedly mounted on the upper end of the mounting plate 3 4. The inner side of the conveying body 1 is provided with a rotating drum 5, a transmission mechanism 6 is arranged between the driving motor 4 and the rotating drum 5, and the inner side of the conveying body 1 is fixedly installed with a support plate 7 on the side close to the rotating drum 5, the rotating drum 5 A conveyor belt 8 is provided on the outside of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com