Bridge type hydraulic arch arm mechanical arm bus automatic washing machine

A technology of automatic car washing and manipulator, applied in the direction of vehicle exterior cleaning devices, etc., can solve the problems of car body surface with numerous scratches and no wheels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

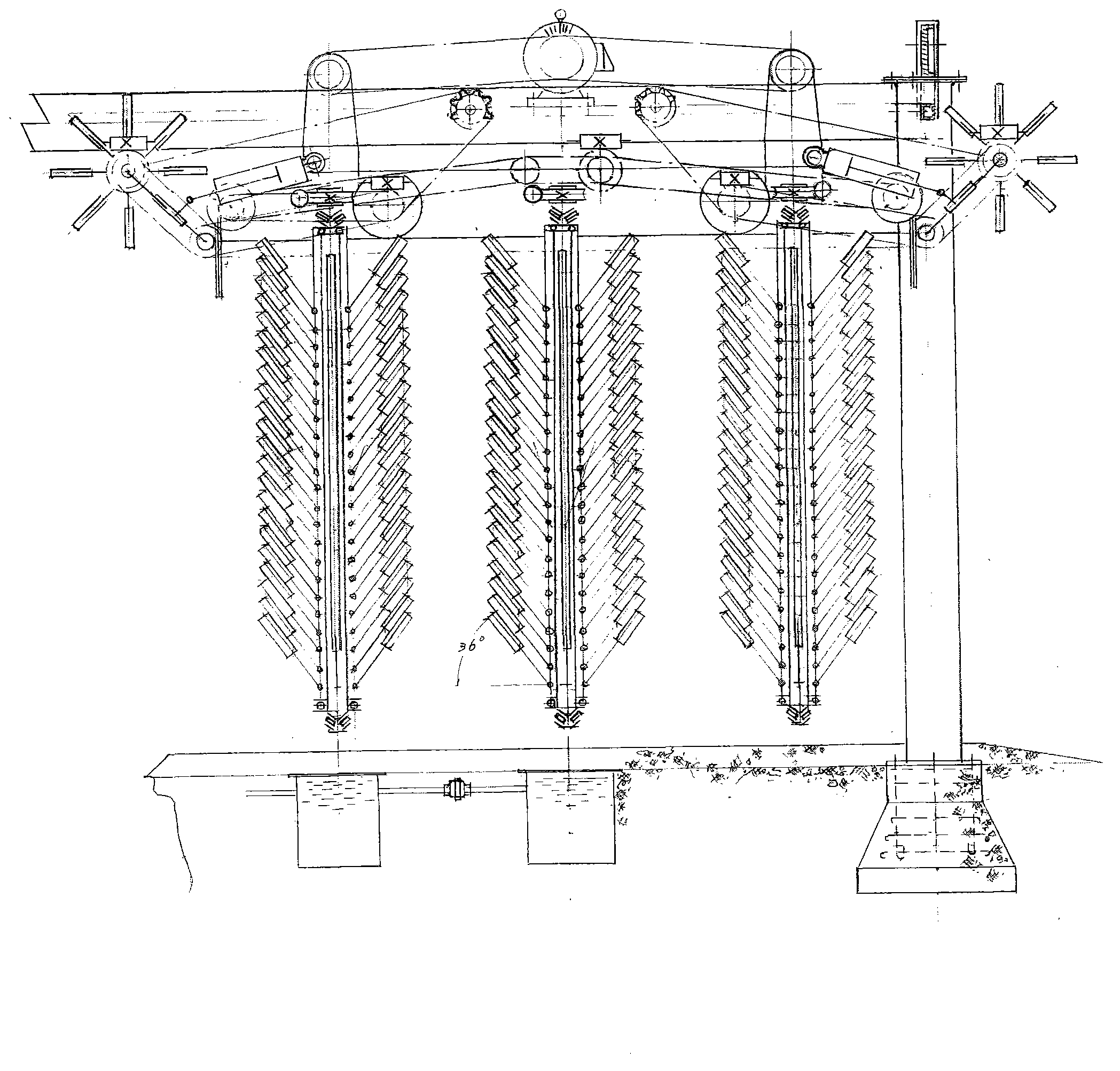

[0020] Embodiment 1, according to Beijing, Shanghai, Shenzhen and Qingdao bus body size structure investigation statistics result is: the car body is long 1160--1500 centimetres, front width 255 centimetres, rear width 250 centimetres, the lower edge of the front face of the car body to The height of the ground plane is 45 cm, the edge of the rear compartment is 50 cm from the ground, the edge of the two sides is 40 cm from the ground level, the edge of the second side is 260 cm from the ceiling, and there is a 40 cm high air-conditioning shell above the ceiling, the total height is 340 cm, and the wheel diameter is 105 cm. cm, the diameter of the wheel chamber is 119 cm, the length of the cantilever of the rearview mirror installed on both sides of the front of the car is 60-75 cm, the height of the mirror frame is 60 cm, the inner distance between the ends of the two cantilever lengths is 267 cm, the distance between the mirror arm and each side of the car body The included a...

Embodiment 2

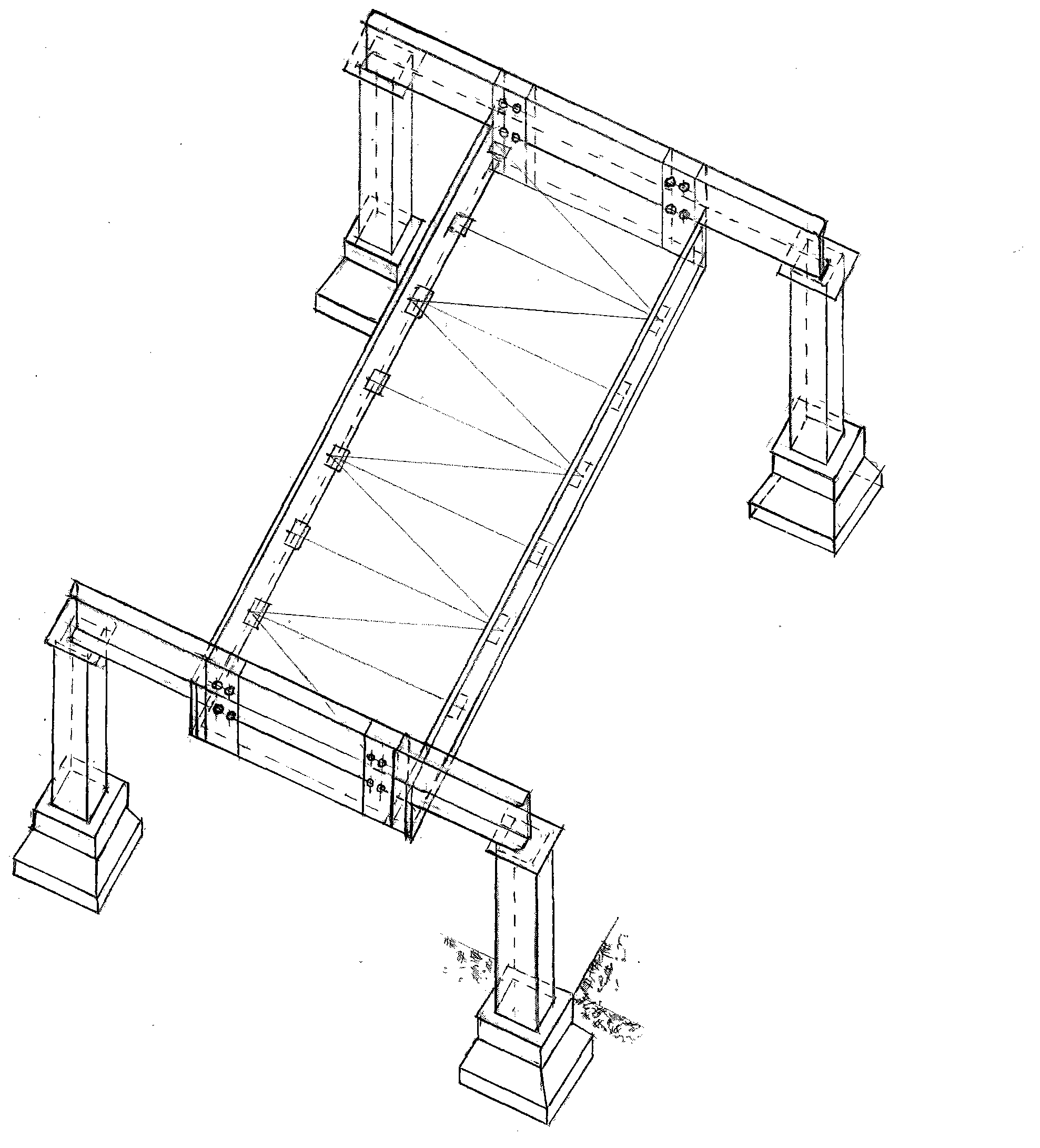

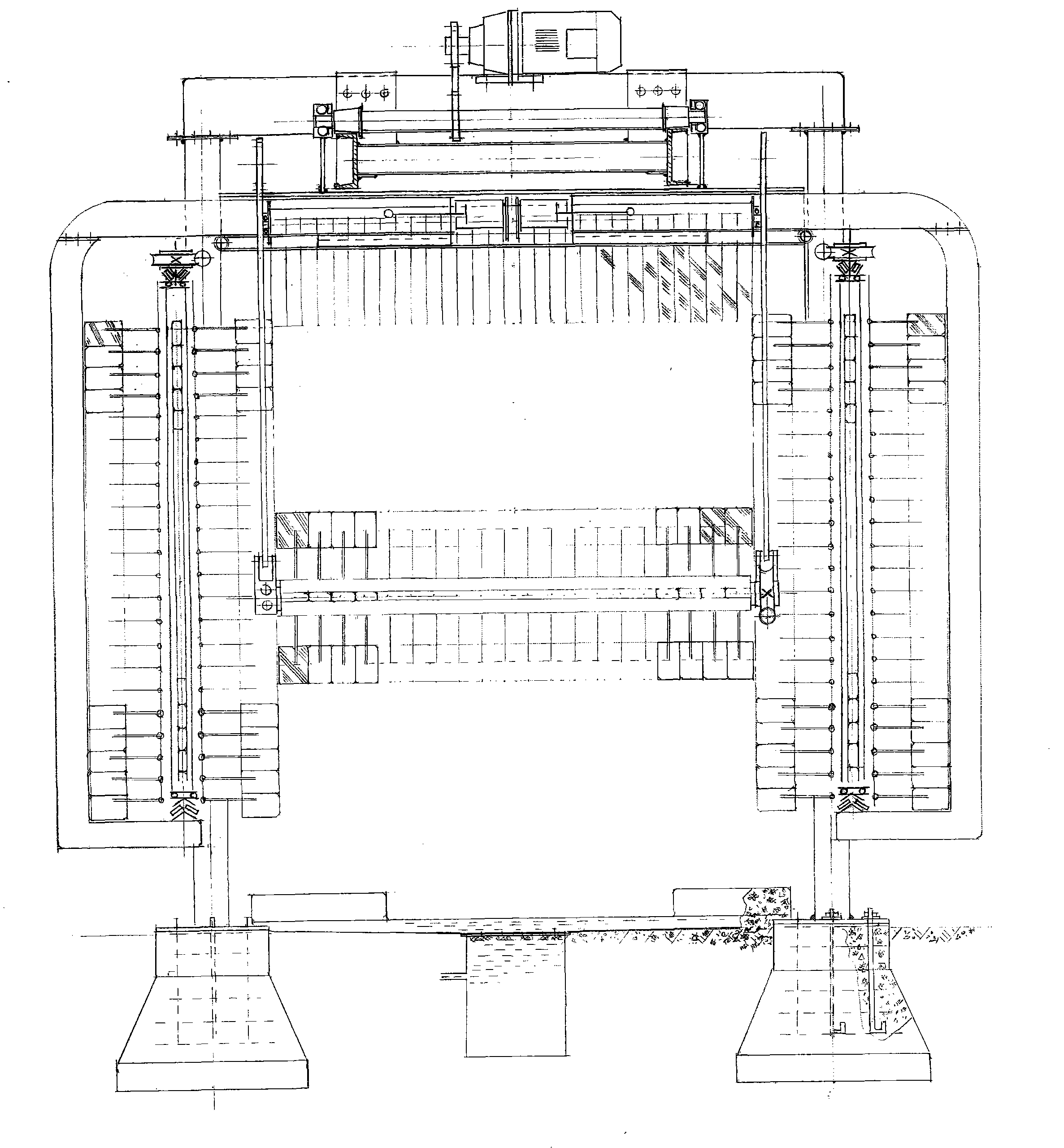

[0021] Embodiment 2: There is a "mouth"-shaped fully enclosed working platform vehicle that surrounds the track truss beam and automatically reciprocates according to the program figure 2 , the working platform body selects B80b508 / 5 hot-rolled unequal angle steel according to the GB167-88 standard, and welds a frame structure with a length of 400 cm, a width of 256 cm, and a thickness of 40 cm. The two ends of the left and right sides of the working platform body are respectively Use four isosceles trapezoidal hanging connecting plates with a height of 60 cm, a width of 25 cm, and a thickness of 1.4 cm for welding connection, and the top of the semicircle is welded and connected to the outer circular surface of the bearing box made of A3 material on the four axle heads of the two axles Above, the inner rings of the bearings assembled on the shaft heads of the four axles are locked with double caps and locking plates. The 208 bearing axle box has a sealing gland and an oil seal...

Embodiment 3

[0022] Embodiment 3: there are two vertical and horizontal bisectors perpendicular to each other at the center point of the upper horizontal plane in the frame platform body structure bottom of 400 centimeters in length, 256 centimeters in thickness and 40 centimeters in thickness, and a parallel line is respectively drawn at 175 centimeters away from the horizontal vertical bisector, both sides, Two reels with a length of 250 cm and a diameter of 30 cm and a diameter of 50 cm at both ends are respectively installed on the two parallel lines. The two ends of the reel shaft are respectively installed with 207 bearings. Connection, the shaft head on the left side of the 207 bearing box is installed with a TG254 sprocket at a position extending 10 cm. The sprocket and the shaft head are connected with a hook head flat key. The two sprockets on the output shaft of the aluminum alloy worm reducer with a ratio of 50 form a chain transmission structure. Hundreds of them are inlaid on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com