Crawler hydraulic support assembling machine

A hydraulic support, crawler technology, applied in the direction of pillar/support, crane, transportation and packaging, etc., can solve the problems of low efficiency, time-consuming, labor intensity of workers and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

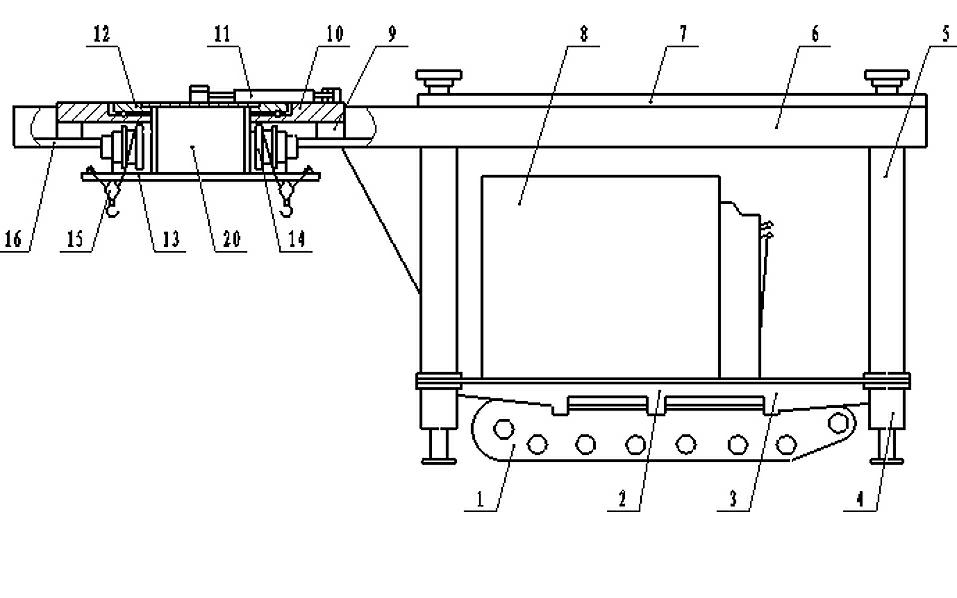

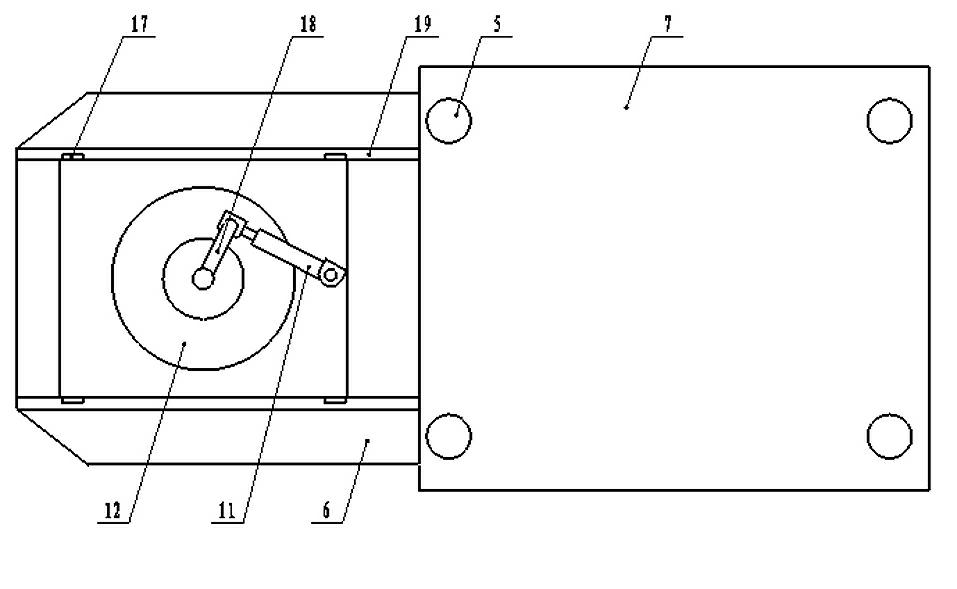

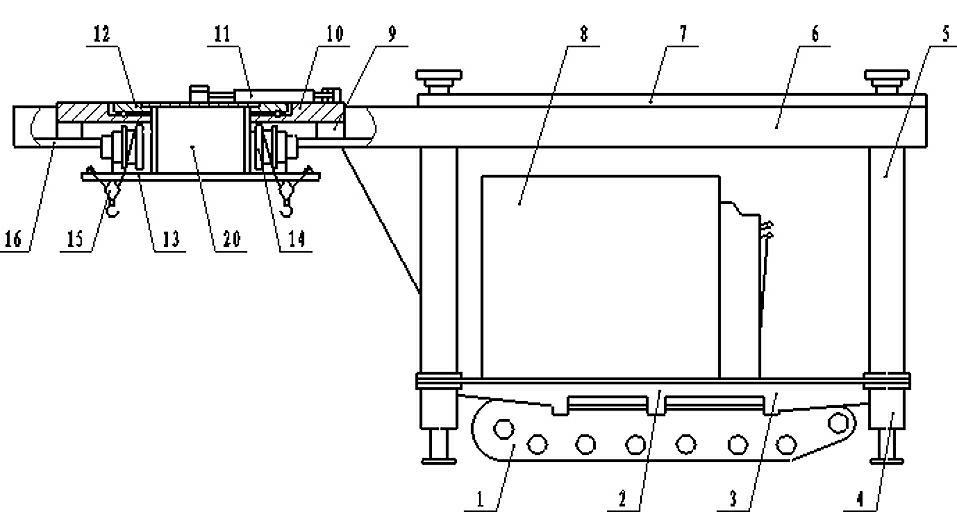

[0017] Such as figure 1 , figure 2 As shown, the crawler-type hydraulic support installation machine of the present invention includes a running part 1, a frame 2, a cantilever beam 6 and a rotatable hook part 9, and the two running parts 1 are symmetrically arranged on the lower part of the frame 2, parallel to the running part 1 The two cantilever beams 6 are symmetrically arranged on both sides of the upper part of the frame 2, and a rotatable hook part 9 is arranged between the two cantilever beams 6.

[0018] The frame 2 includes: a base 3, a support cylinder 5 and a frame top cover 7, the base 3 is fixed on the walking part 1, a support cylinder 5 is respectively fixed on the four corners of the base 3, and the support cylinder 5 is vertical Installation, the cylinder body of the support cylinder 5 is fixed on the base 3, the piston rod of the support cylinder 5 is vertically upward and higher than the frame top cover 7, the base 3, the cylinder body of the support cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com