Front and rear roller crosslinked cloth-traction mechanism for quilting machine

A technology of quilting machine and rear roller, which is applied in the direction of cloth feeding mechanism, sewing machine components, sewing machine for sewing quilts, etc. It can solve the problems affecting the quilting effect, broken threads, jumping threads, etc., so as to improve the quilting effect and solve the problem. The effect of pattern distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

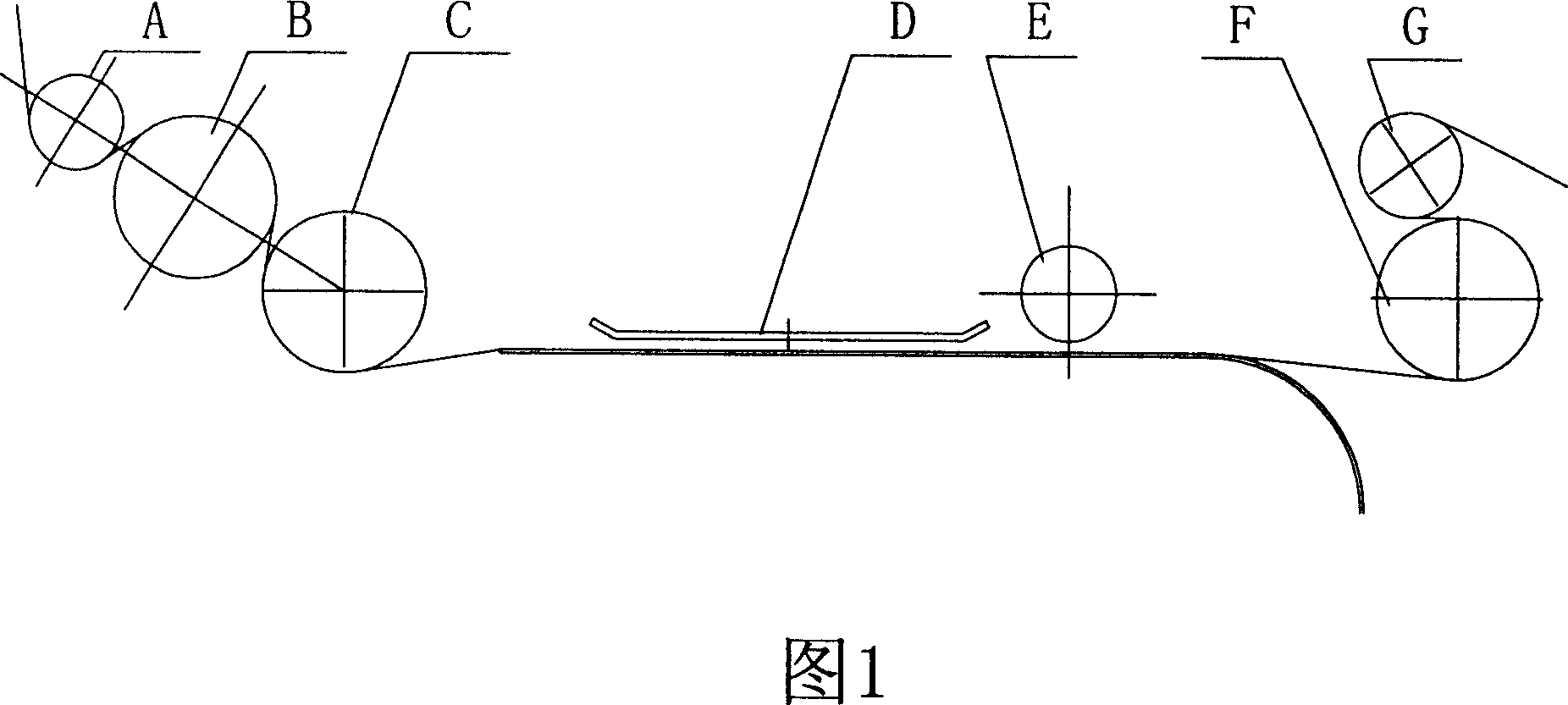

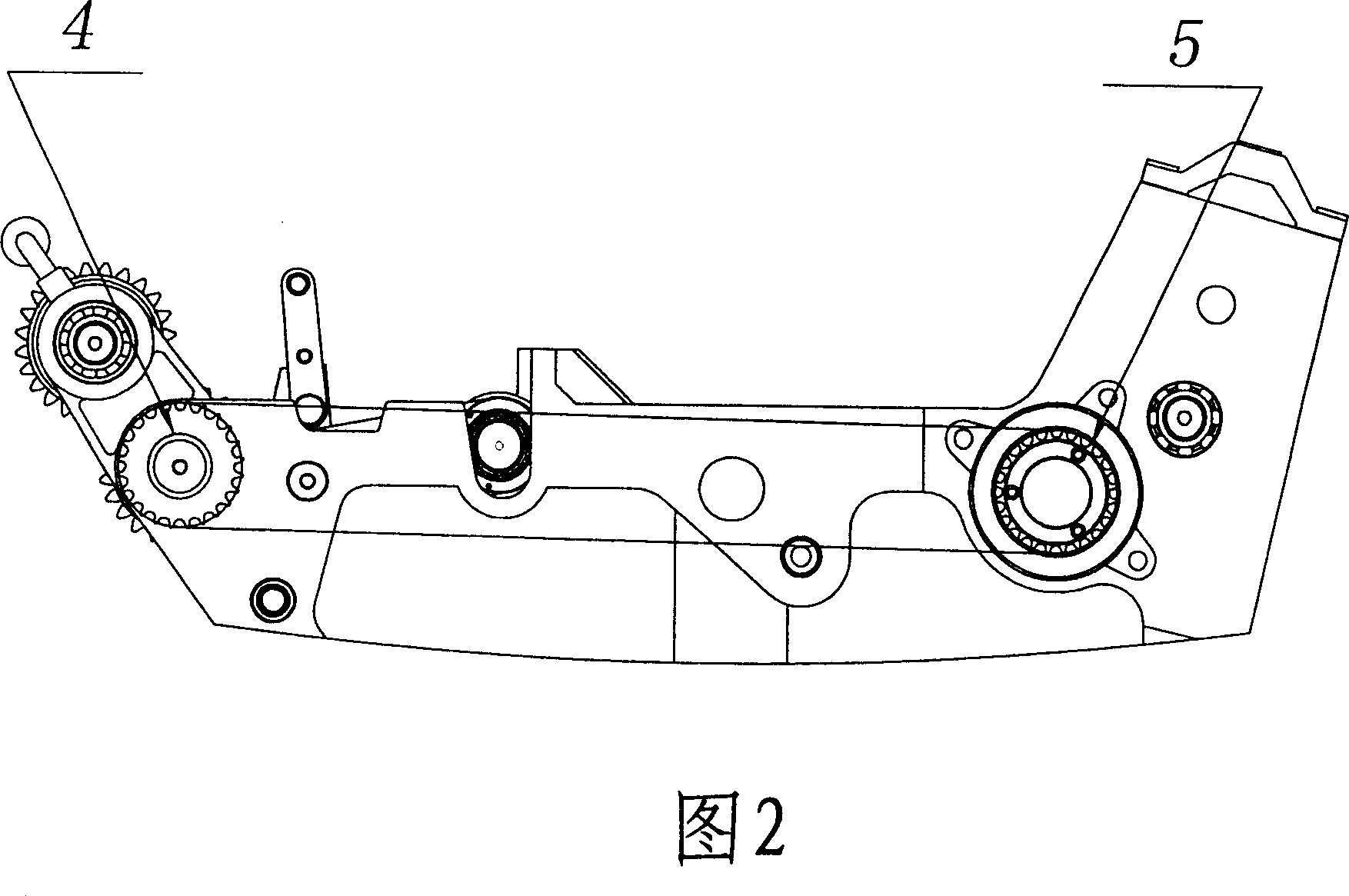

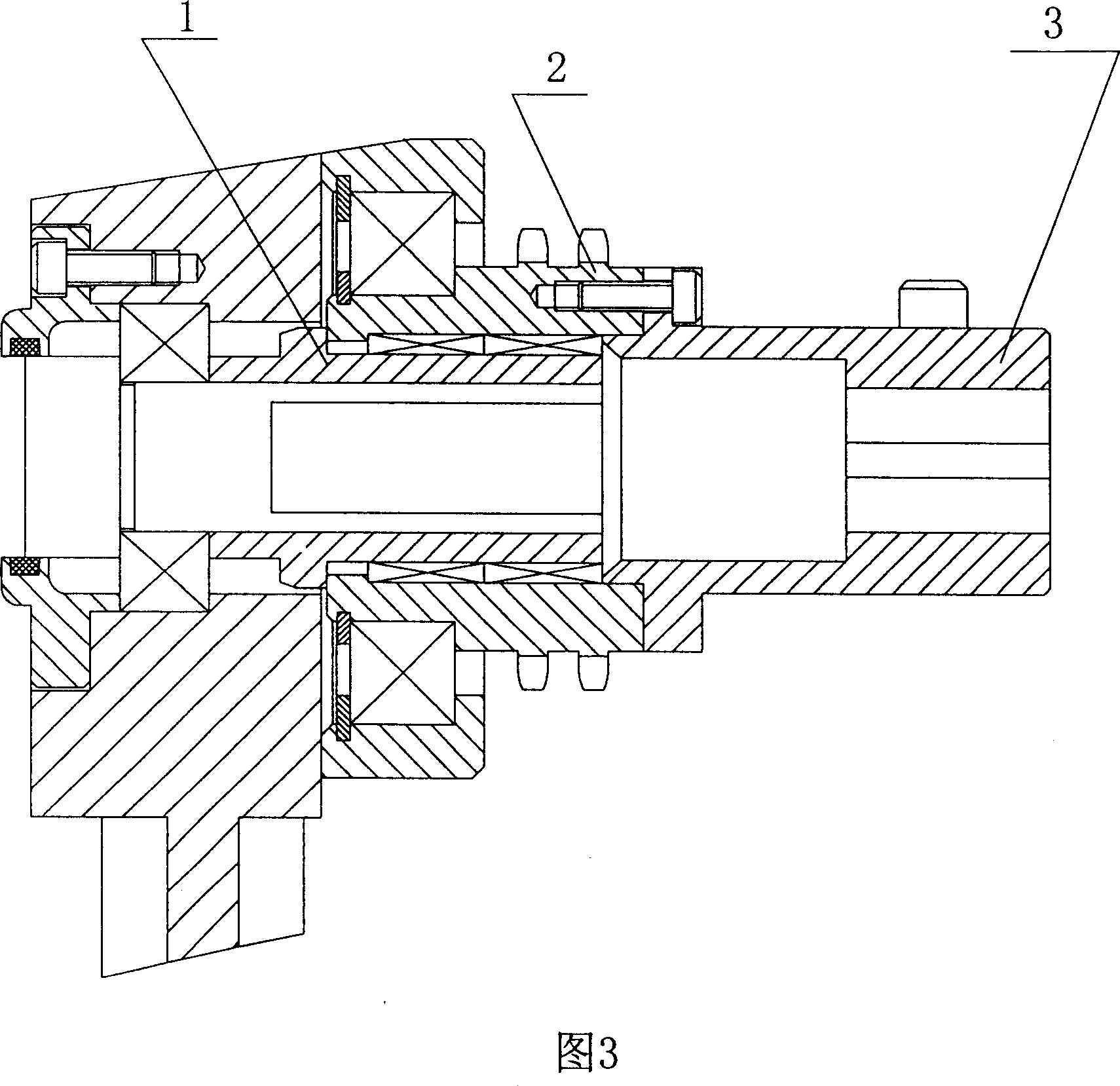

[0010] Referring to Figures 2 and 3, this embodiment has a front roller set, a rear roller set, a motor, a rolling spline, a rolling spline sleeve 3, a rear roller sprocket 2, a bearing flat hole sleeve 1. The front roller group is composed of a front main roller and a front auxiliary roller, and the rear roller group is composed of a rear main roller, a rear auxiliary roller and a rear smooth roller. The motor is a servo motor. The motor drive is connected to the input end of the rolling spline, and the auxiliary output end of the rolling spline is assembled with the rolling spline sleeve 3, the rear roller sprocket 2 and the bearing flat hole sleeve 1 in sequence. The input ends of the rear main roller and the front main roller are equipped with single The one-way rotating device 4, 5, the one-way rotating device 5 of the rear main roller is installed in the rear roller sprocket 2, and the one-way rotating device 4 of the front main roller is connected with the rear roller sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com