Process for producing unit plate of unit-type curtain wall and operation console thereof

A technology of curtain wall units and operating consoles, applied to walls, building components, buildings, etc., can solve problems such as low work efficiency, unsatisfactory, non-adjustable width and height, etc., to improve production efficiency, improve product quality, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

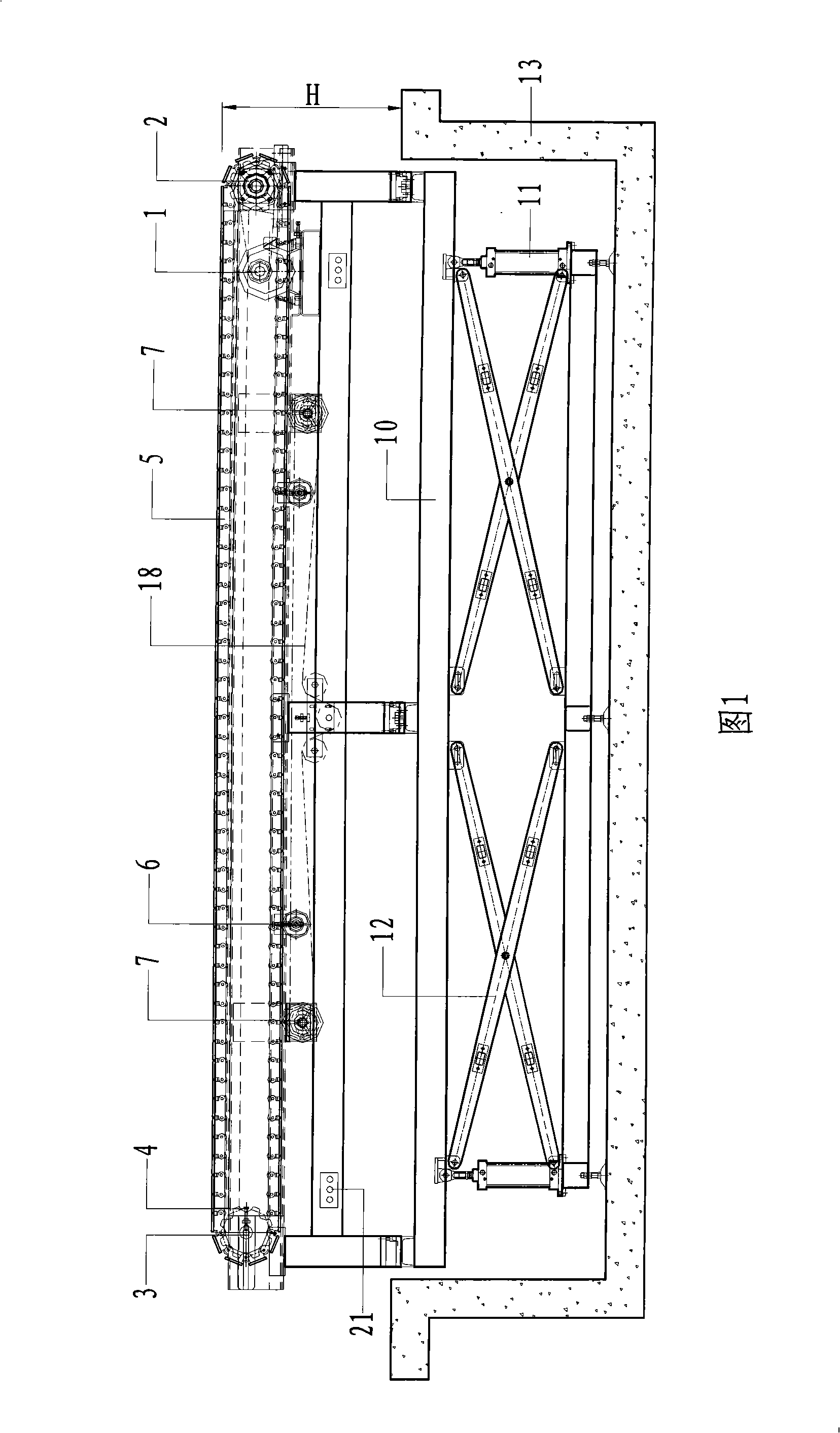

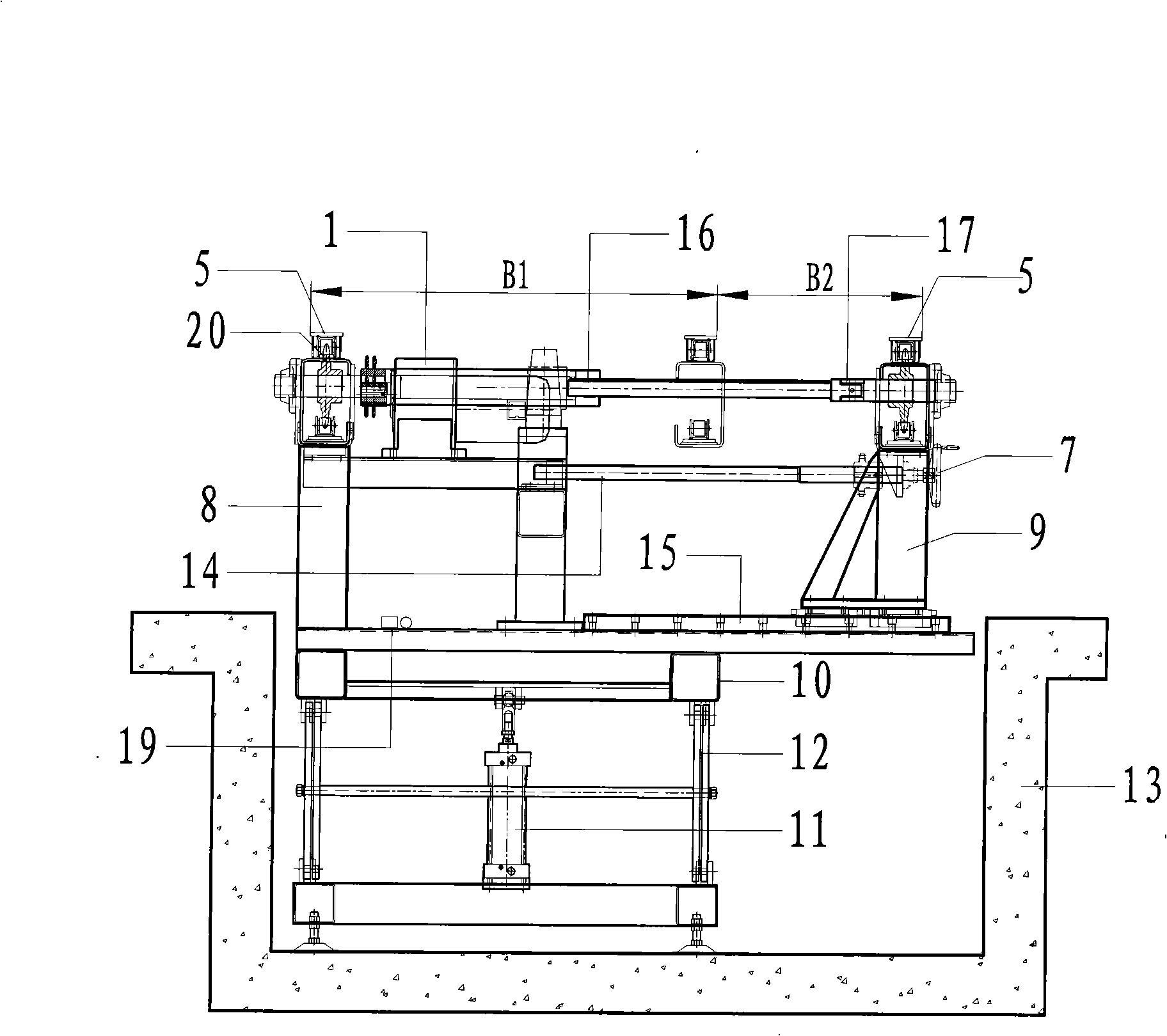

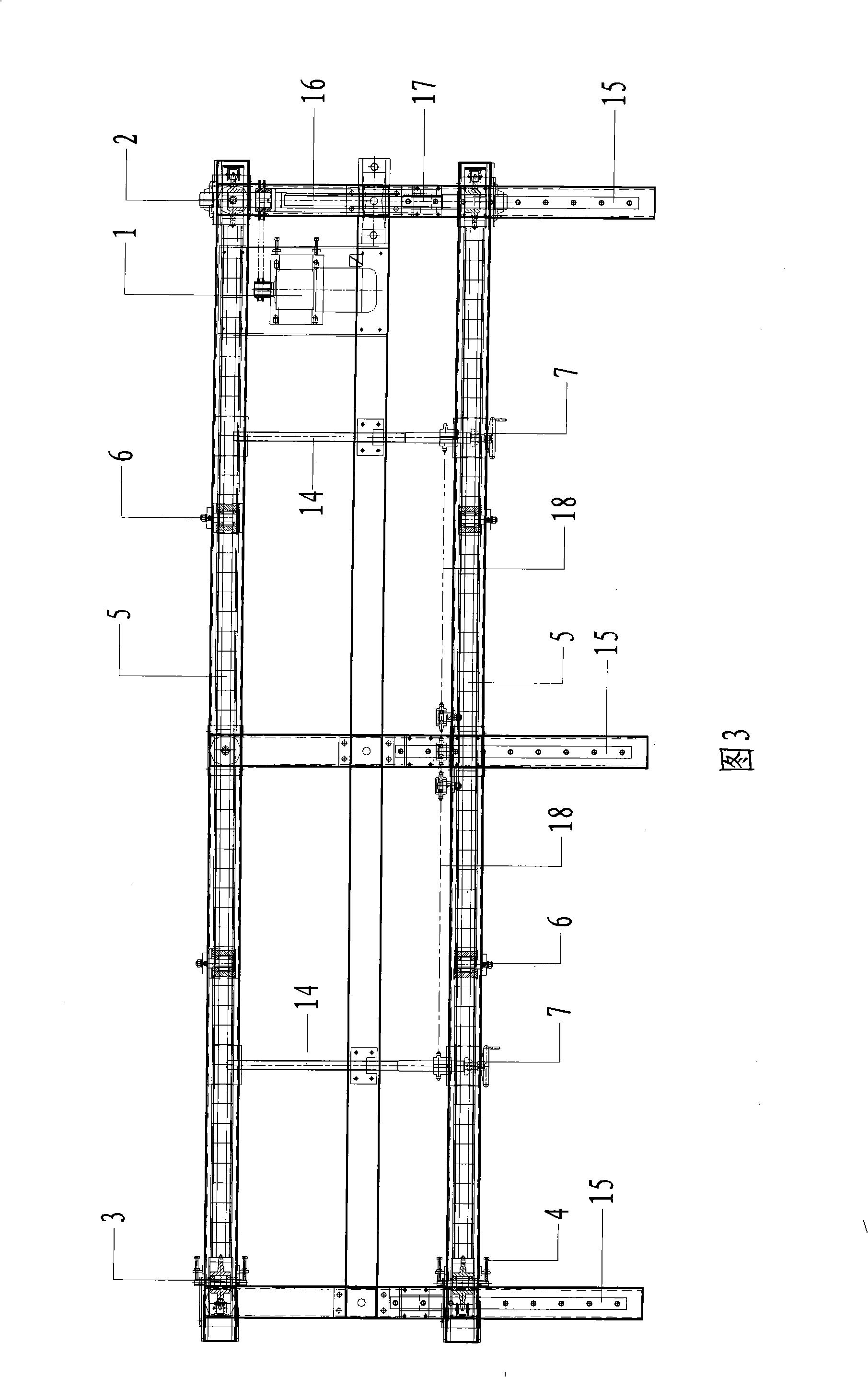

[0014] Adopt the method of the present invention to form production line, be divided into six operations. Each process can use one or more chain conveyors as the operation table, arranged in a line. The first process is the metal frame assembly, including wearing rubber strips and sealing the process holes; the second process is the installation of the inner lining board. This process is equipped with a crane, which can realize the flipping of the frame, install the inner lining board, insulation cotton, etc. and seal the glue, and the frame Film protection, after the plate is rotated, enter the next process; process three is metal frame quality inspection, fill in the quality form; process four is panel assembly, this process is also equipped with a crane, the glass is absorbed by electric suction cups, first passed the grating inspection, and then passed the inspection Placed on the unit frame; the fifth process is glue injection, which adopts a fully enclosed constant tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com