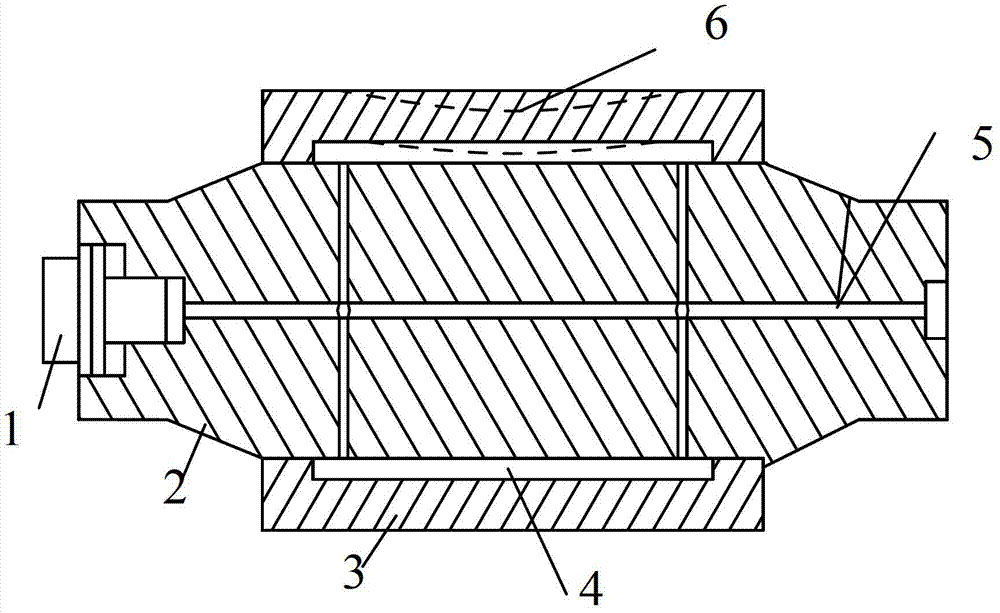

Method for designing inner roller type curve of sleeve of variable crown (VC) roller

A technology of curve design and roll sleeve, applied in computing, special data processing applications, instruments, etc., can solve problems such as double-sided corrugated plate defects of strip at the exit of the rolling mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

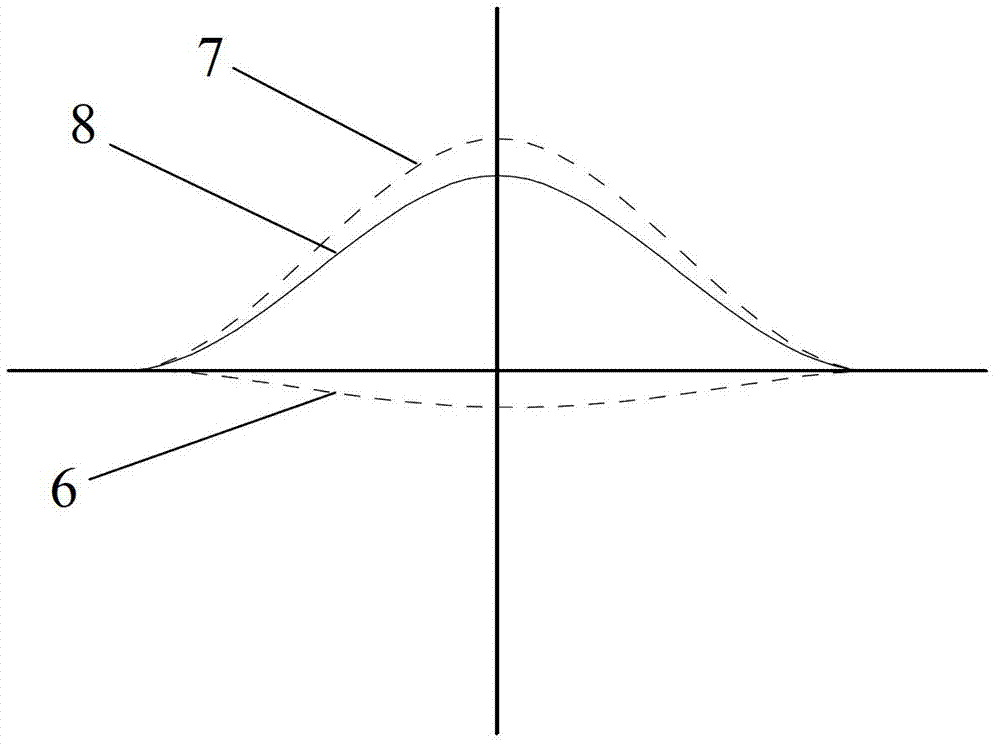

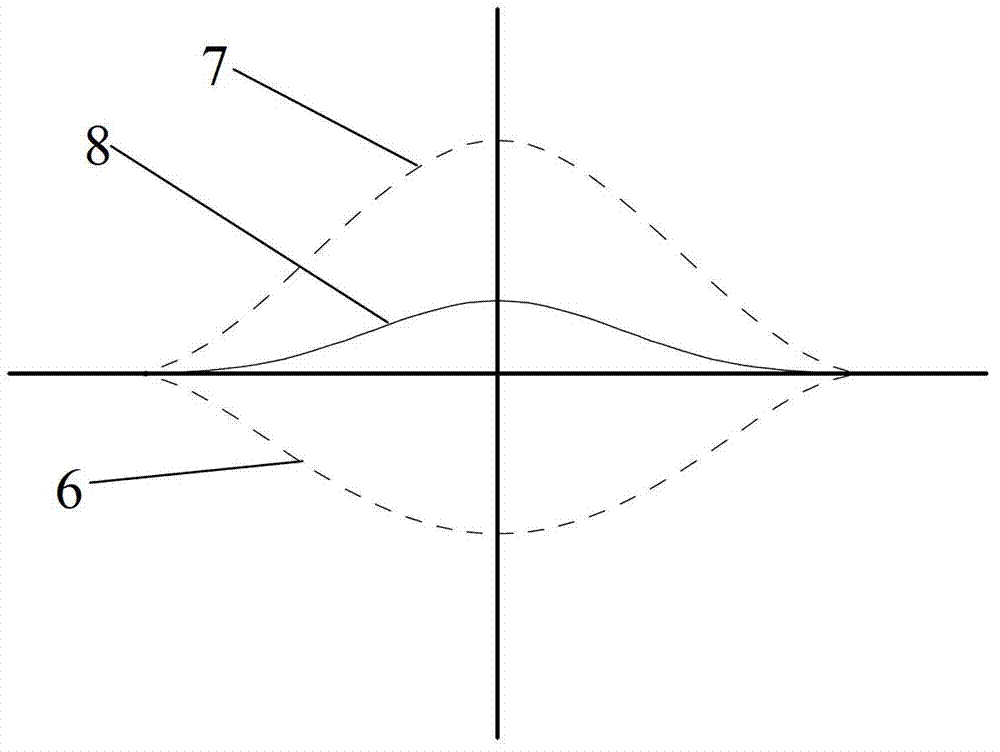

[0052] attached Figure 6 It is a general flow chart of the design method for the roll profile curve in the VC roll sleeve according to the present invention; Figure 7 It is a flow chart of calculation of inner roll shape optimization curve parameters in the present invention. Taking 7 groups of typical specification products as an example, with the help of the attached Figure 6 , attached Figure 7 To describe the comprehensive optimization process of the sleeve inner roll shape and related effects.

[0053] First, in step 1, the equipment characteristic parameters of the VC mill are collected, mainly including: diameters of work rolls and backup rolls D w =510mm,D b =1400mm, original roll shape distribution value of work roll and backup roll ΔD wi =0,ΔD bi =0, work roll and backup roll body length L 1 =1650mm,L 2 =1620mm, cylinder distance between inner and outer bending rolls of work rolls l 21 =2320mm, l 22 =3120mm, press down the screw center moment l 1 =2720...

Embodiment 2

[0086] attached Figure 6 It is a general flow chart of the design method for the roll profile curve in the VC roll sleeve according to the present invention; Figure 7 It is a flow chart of calculation of inner roll shape optimization curve parameters in the present invention. Taking 7 groups of typical specification products as an example, with the help of the attached Figure 6 , attached Figure 7 To describe the comprehensive optimization process of the sleeve inner roll shape and related effects.

[0087] First, in step 1, the equipment characteristic parameters of the VC mill are collected, mainly including: diameters of work rolls and backup rolls D w =510mm,D b =1400mm, original roll shape distribution value of work roll and backup roll ΔD wi =0,ΔD bi =0, work roll and backup roll body length L 1 =1650mm,L 2 =1620mm, cylinder distance between inner and outer bending rolls of work rolls l 21 =2320mm,l 22 =3120mm, press down the screw center moment l 1 =2720m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com