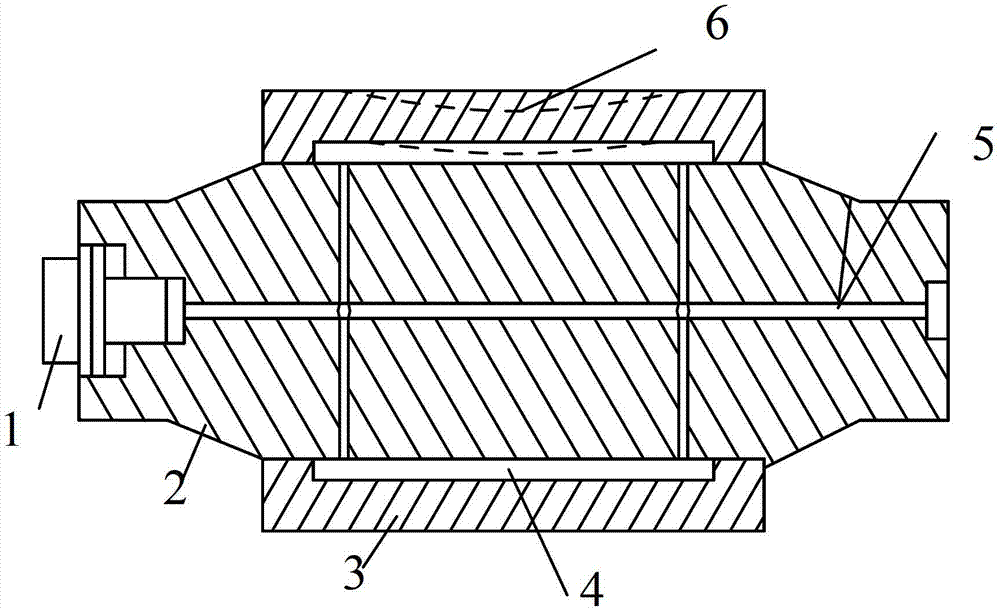

Method for designing inner roller type curve of sleeve of variable crown (VC) roller

A roll and roll shape technology, applied in the field of roll shape curve design in VC roll sleeve, can solve the problems of double-sided corrugated plate shape defects of the strip at the exit of the rolling mill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

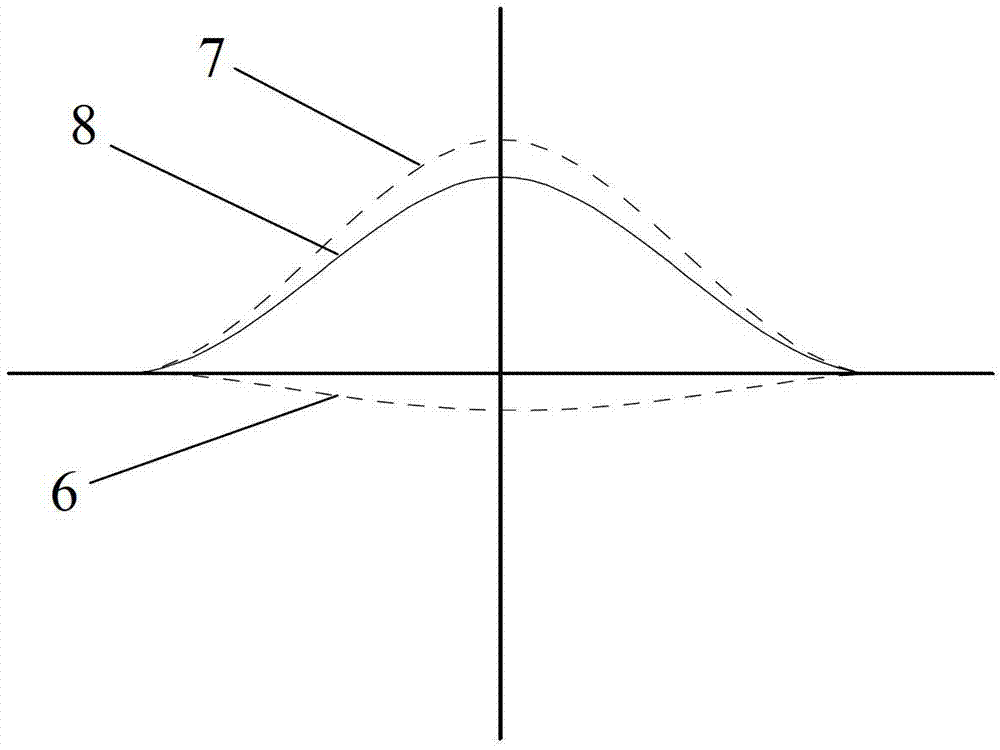

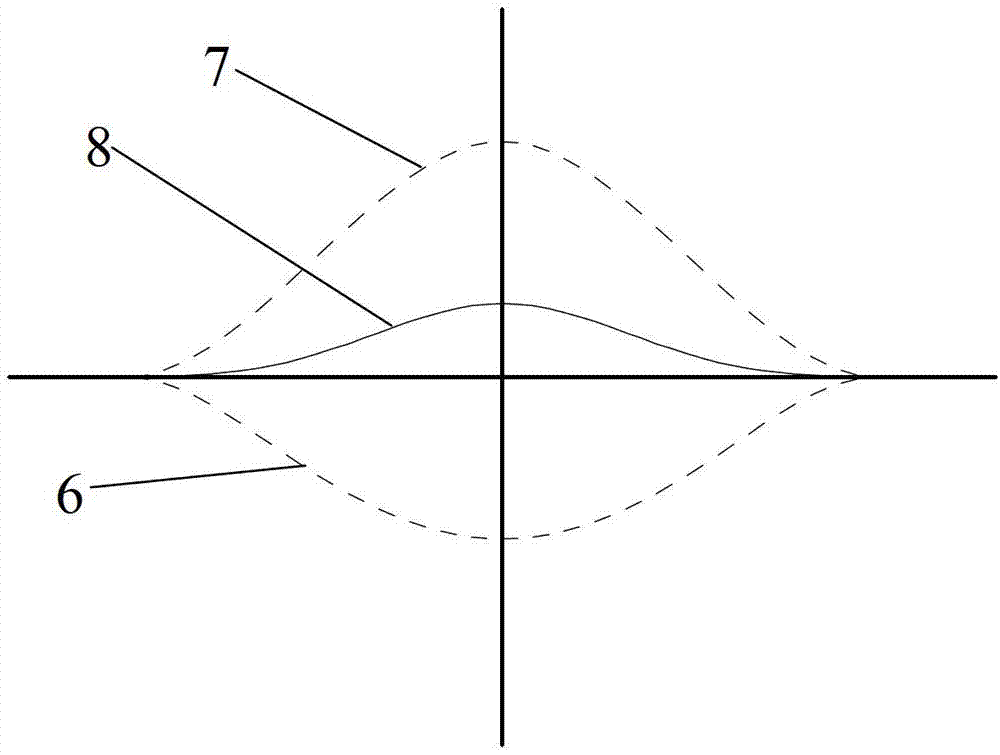

[0052] Attached Image 6 It is the general flow chart of the design method of the roller profile curve in the VC roll sleeve according to the present invention; Figure 7 It is a flow chart for calculating the parameters of the inner roll shape optimization curve in the present invention. Now take 7 groups of typical specification products as an example, with the help of attached Image 6 , Attached Figure 7 To describe the comprehensive optimization process of the roller shape in the sleeve and related effects.

[0053] First, in step 1, collect the equipment characteristic parameters of the VC rolling mill, mainly including: the diameter D of the work roll and the support roll w =510mm,D b =1400mm, original roll shape distribution value of work roll and support roll ΔD wi =0,ΔD bi =0, the length of work roll and support roll body L 1 =1650mm,L 2 =1620mm, the distance between the inner and outer bending cylinders of the work roll l 21 =2320mm,l 22 =3120mm, center moment of scre...

Embodiment 2

[0086] Attached Image 6 It is the general flow chart of the design method of the roller profile curve in the VC roll sleeve of the present invention; Figure 7 It is a flow chart for calculating the parameters of the inner roll shape optimization curve in the present invention. Now take 7 groups of typical specification products as an example, with the help of attached Image 6 , Attached Figure 7 To describe the comprehensive optimization process of the roller shape in the sleeve and related effects.

[0087] First of all, in step 1, the equipment characteristic parameters of the VC rolling mill are collected, mainly including: the diameter D of the work roll and the support roll w =510mm,D b =1400mm, original roll shape distribution value of work roll and support roll ΔD wi =0,ΔD bi =0, the length of work roll and support roll body L 1 =1650mm,L 2 =1620mm, the distance between the inner and outer bending cylinders of the work roll l 21 =2320mm,l 22 =3120mm, center moment of s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap