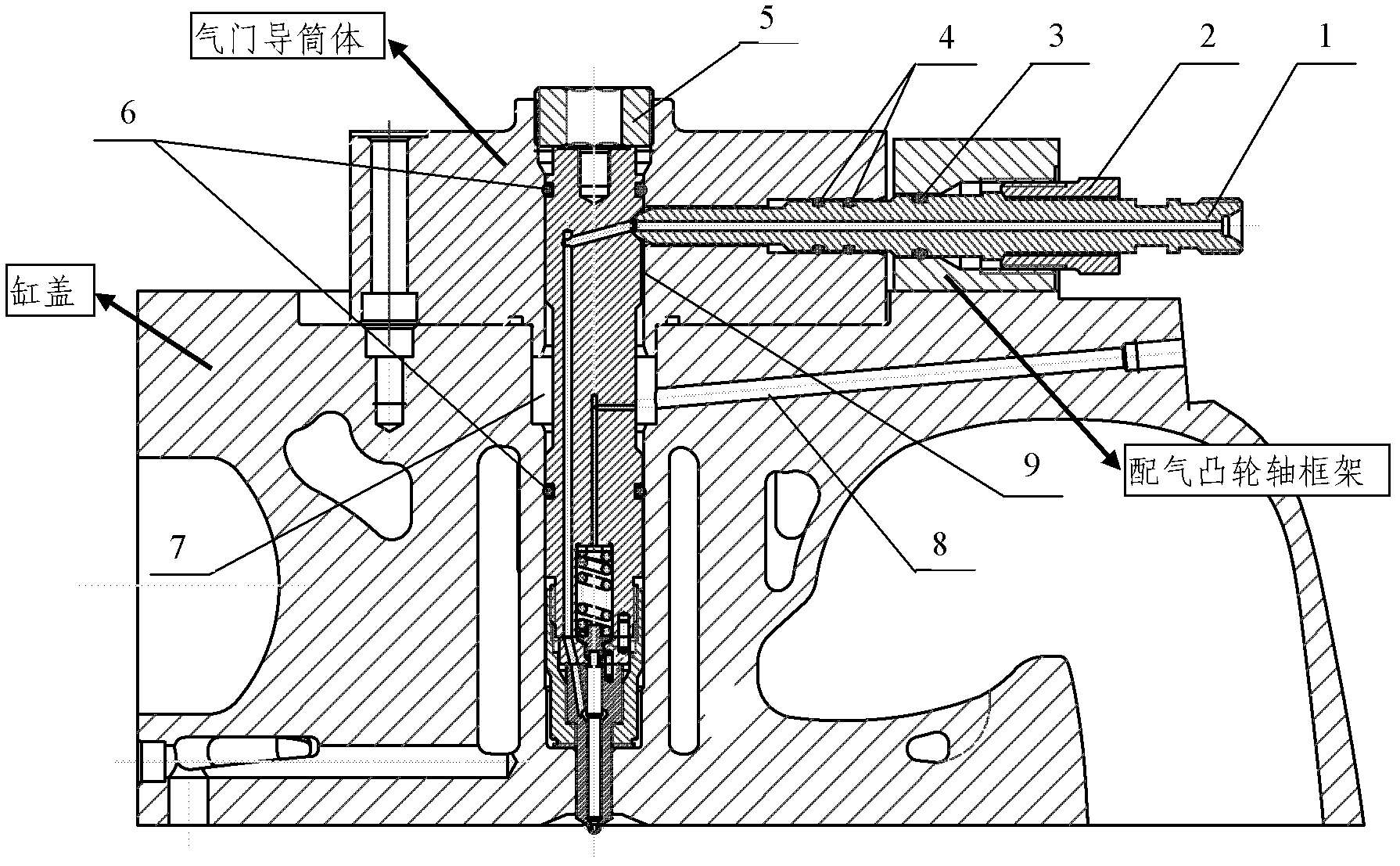

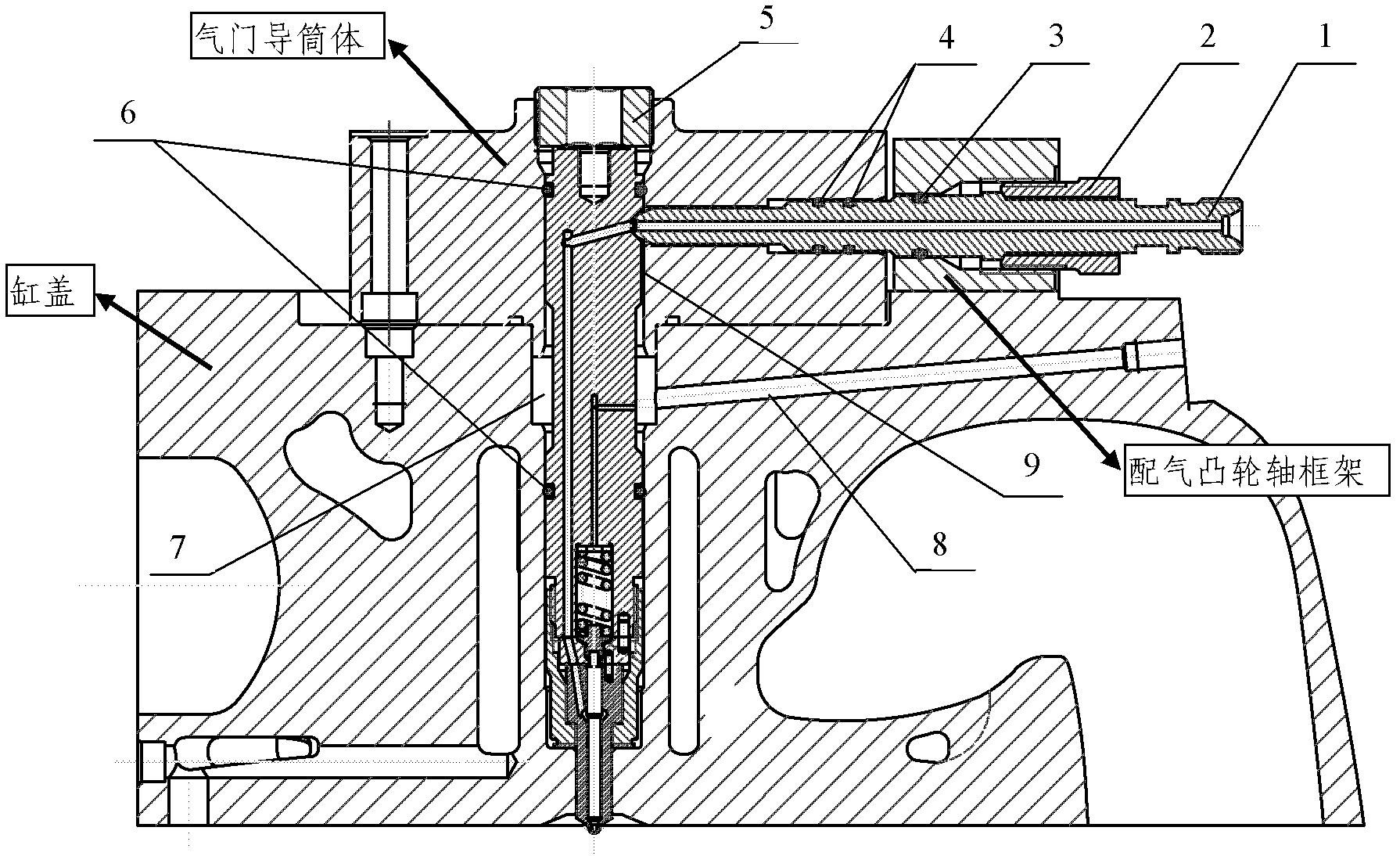

Embedded oil charging structure for high-pressure fuel oil system

A high-pressure fuel, embedded technology, applied in the charging system, fuel injection device, engine components, etc., can solve the problems of injection pressure drop, injection delay increase, control accuracy reduction, etc., to achieve smooth oil return, easy installation, short The effect of high pressure oil pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embedded oil inlet structure of a high-pressure fuel system, the related components include a side oil inlet pipe 1, a side compression nut 2, a top compression nut 5, an O-ring seal 3, an O-ring seal 4, an O-ring seal The ring 6 is characterized in that the lateral oil inlet pipe 1 is embedded in the frame of the distribution camshaft and the valve guide cylinder; Press the lateral oil inlet pipe 1 against the side wall of the fuel injector with the compression nut 2, and tighten the lateral compression nut 2 on the frame of the gas distribution camshaft; use the top compression nut 5 to compress the fuel injector assembly In the inner hole of the cylinder head, the top compression nut 5 is tightened on the valve guide cylinder body; two O-rings 4 are arranged in cooperation with the side oil inlet pipe 1 and the valve guide cylinder body, and the side oil inlet pipe 1 is connected with the valve camshaft An O-ring seal 3 is arranged on the frame, and an O-ring 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com