Pressure balance valve for liquid flow battery

A liquid flow battery and balance valve technology, applied in the direction of balance valves, fuel cells, fuel cell additives, etc., can solve problems such as blockage of battery stack flow channels, unusable applications, and polluted electrolytes, and achieve stable charge and discharge performance and extended battery life. Battery life, the effect of improving battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

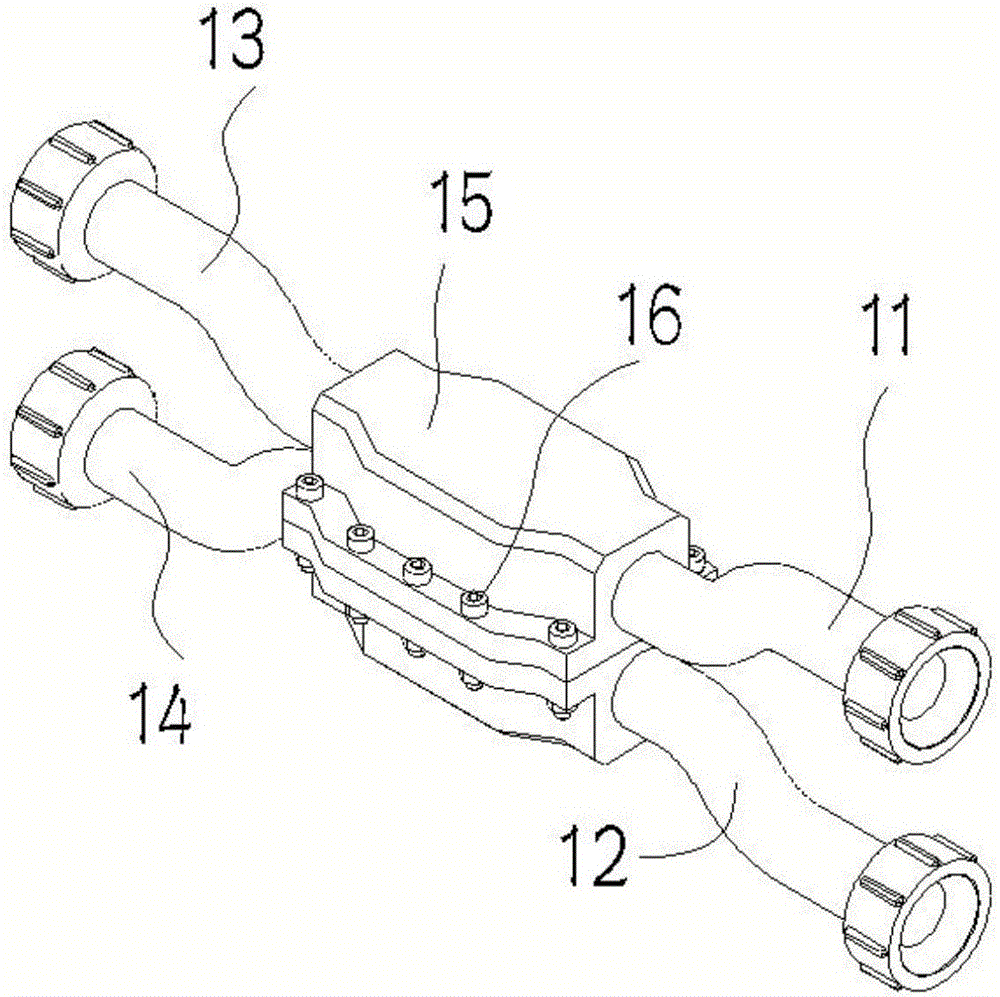

[0031] like figure 1 The shown pressure balance valve for the flow battery includes two symmetrically arranged valve bodies 15, which are connected by fasteners 16; the valve bodies 15 each have a chamber, respectively a positive electrode pressure balance chamber 221a and a negative electrode pressure balance chamber 221a. Chamber 221b, the openings of the two chambers 221a and 221b are arranged oppositely; the electrolyte flow channel, which is arranged on the two ends of the chamber, respectively includes the positive electrolyte inlet 11 and the positive electrolyte on the two ends of a chamber. outlet 13, and the negative electrode electrolyte inlet 12 and the negative electrode electrolyte outlet 14 that are arranged on the two ends of the other chamber, and the positive electrode electrolyte inlet 11 and the negative electrode electrolyte inlet 12 are respectively positioned on the same side of the valve body, and the The positive electrode electrolyte outlet 13 and the...

Embodiment 2

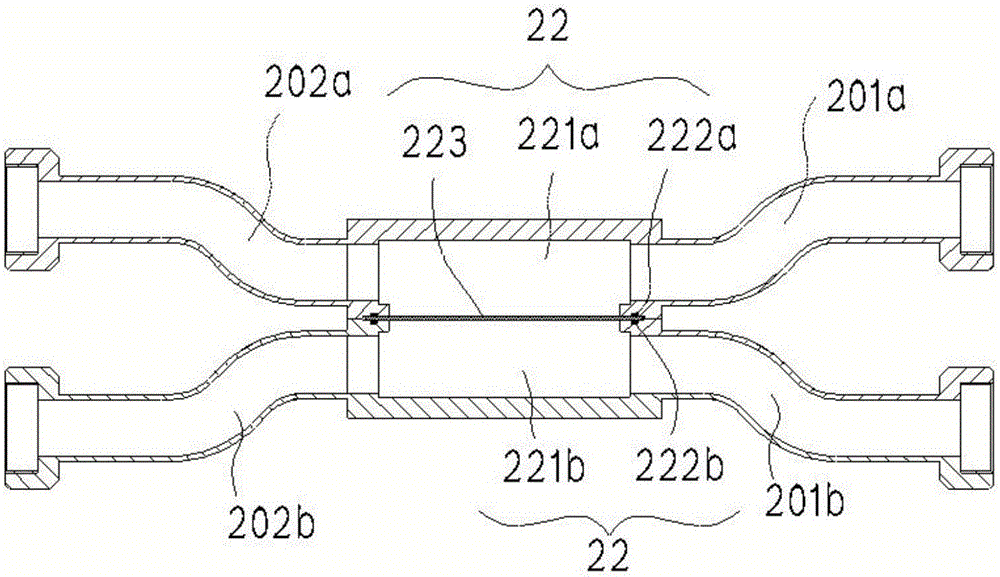

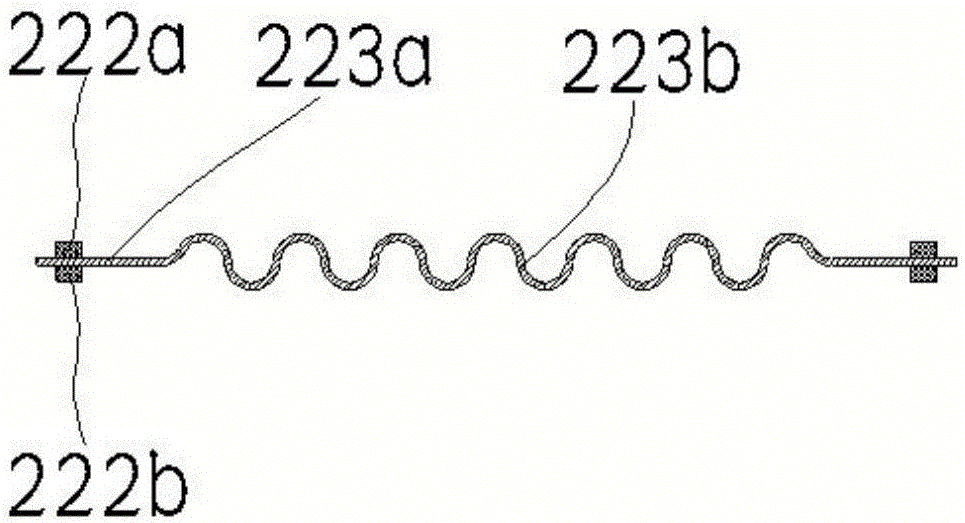

[0035] like figure 2The pressure balance valve for the flow battery with the structure shown, from the cross-section of the pressure balance valve 20 for the flow battery, includes two symmetrically arranged valve bodies 22, which are connected by fasteners; the two valve bodies respectively have a positive electrode balance The chamber 221a and the negative balance chamber 221b, the openings of the two balance chambers 221a and 221b are arranged oppositely; The positive electrode electrolyte solution inlet 201a and the positive electrode electrolyte solution outlet 202a at both ends of 221a, and the negative electrode electrolyte solution inlet 201b and the negative electrode electrolyte solution outlet 202b arranged at both ends of the negative electrode balance chamber 221b, and the positive electrode electrolyte solution inlet 201a and the negative electrode Electrolyte inlet 201b is respectively positioned on the same side of the two valve bodies 22, and positive electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com